Question: Case 13-2 Plastic Cable Clips In mid-September Robyn Pemberton, purchasing officer in the laundry division of Fisher & Paykel Limited, lo- cated in Auckland, New

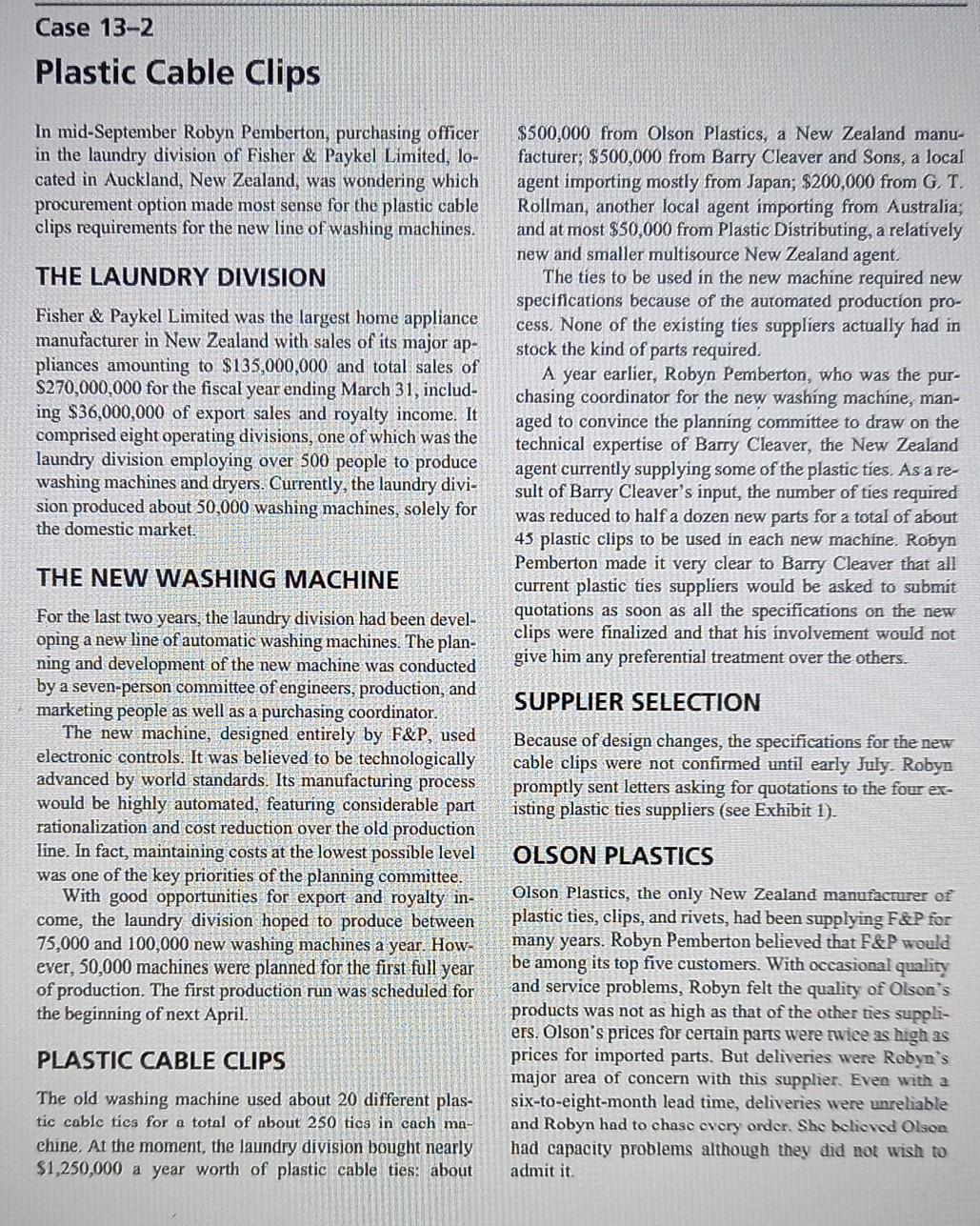

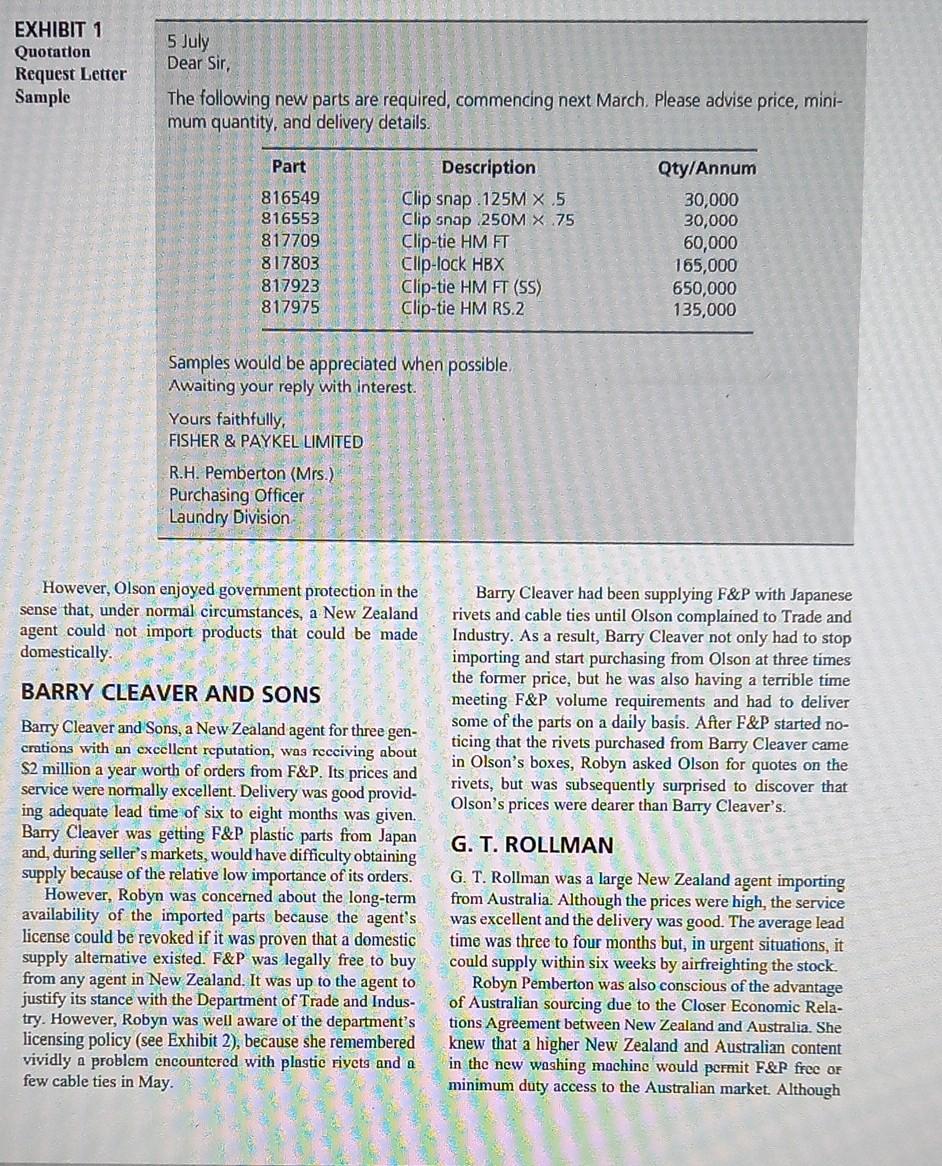

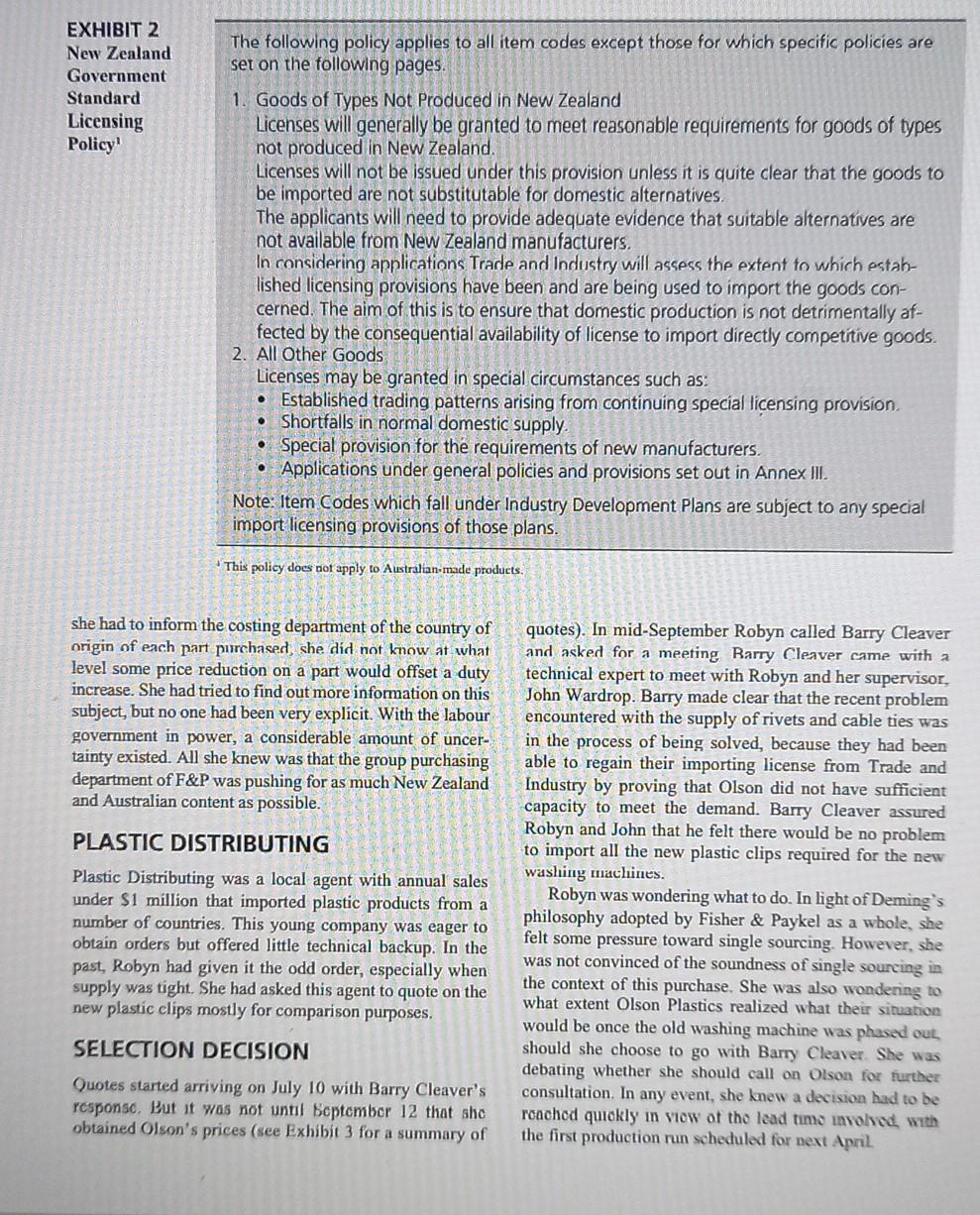

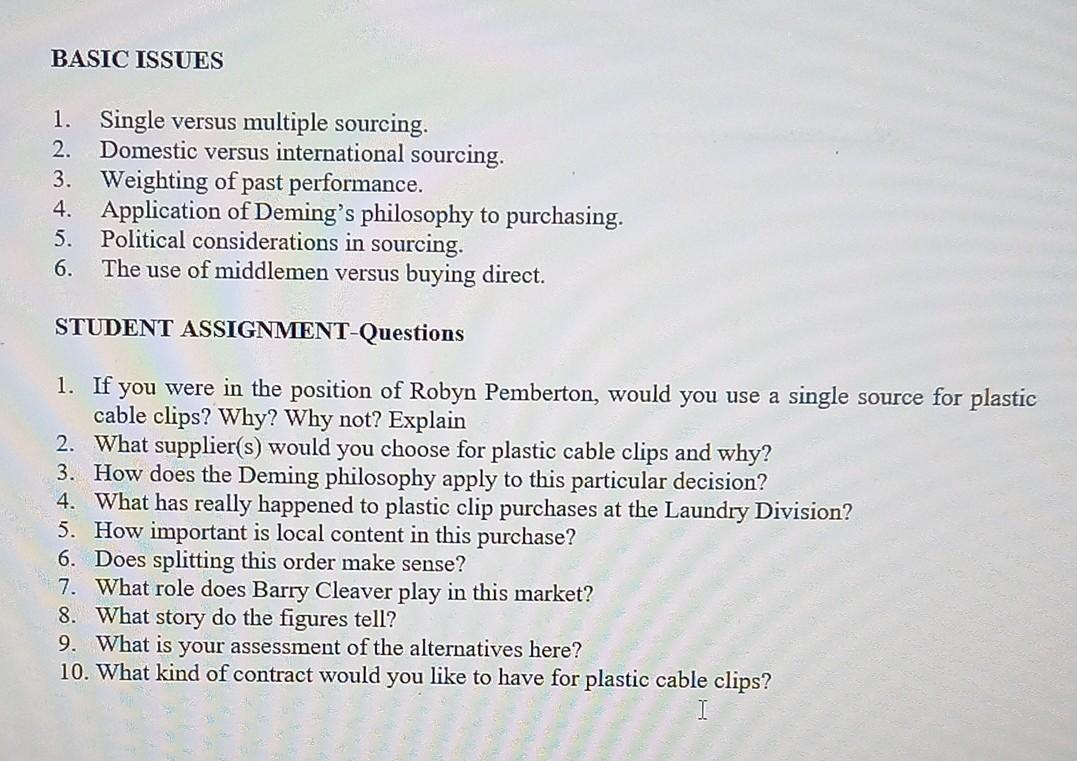

Case 13-2 Plastic Cable Clips In mid-September Robyn Pemberton, purchasing officer in the laundry division of Fisher & Paykel Limited, lo- cated in Auckland, New Zealand, was wondering which procurement option made most sense for the plastic cable clips requirements for the new line of washing machines. THE LAUNDRY DIVISION Fisher & Paykel Limited was the largest home appliance manufacturer in New Zealand with sales of its major ap- pliances amounting to $135,000,000 and total sales of S270,000,000 for the fiscal year ending March 31, includ- ing $36,000,000 of export sales and royalty income. It comprised eight operating divisions, one of which was the laundry division employing over 500 people to produce washing machines and dryers. Currently, the laundry divi- sion produced about 50,000 washing machines, solely for the domestic market. $500,000 from Olson Plastics, a New Zealand manu- facturer; $500,000 from Barry Cleaver and Sons, a local agent importing mostly from Japan; $200,000 from G.T. Rollman, another local agent importing from Australia; and at most $50,000 from Plastic Distributing, a relatively new and smaller multisource New Zealand agent. The ties to be used in the new machine required new specifications because of the automated production pro- cess. None of the existing ties suppliers actually had in stock the kind of parts required. A year earlier, Robyn Pemberton, who was the pur- chasing coordinator for the new washing machine, man- aged to convince the planning committee to draw on the technical expertise of Barry Cleaver, the New Zealand agent currently supplying some of the plastic ties. As a re- sult of Barry Cleaver's input, the number of ties required was reduced to half a dozen new parts for a total of about 45 plastic clips to be used in each new machine. Robyn Pemberton made it very clear to Barry Cleaver that all current plastic ties suppliers would be asked to submit quotations as soon as all the specifications on the new clips were finalized and that his involvement would not give him any preferential treatment over the others. THE NEW WASHING MACHINE SUPPLIER SELECTION For the last two years, the laundry division had been devel- oping a new line of automatic washing machines. The plan- ning and development of the new machine was conducted by a seven-person committee of engineers, production, and marketing people as well as a purchasing coordinator. The new machine, designed entirely by F&P, used electronic controls. It was believed to be technologically advanced by world standards. Its manufacturing process would be highly automated, featuring considerable part rationalization and cost reduction over the old production line. In fact, maintaining costs at the lowest possible level was one of the key priorities of the planning committee. With good opportunities for export and royalty in- come, the laundry division hoped to produce between 75,000 and 100,000 new washing machines a year. How- ever, 50,000 machines were planned for the first full year of production. The first production run was scheduled for the beginning of next April. Because of design changes, the specifications for the new cable clips were not confirmed until early July. Robyn promptly sent letters asking for quotations to the four ex isting plastic ties suppliers (see Exhibit 1). OLSON PLASTICS Olson Plastics, the only New Zealand manufacturer of plastic ties, clips, and rivets, had been supplying F&P for many years. Robyn Pemberton believed that F&P would be among its top five customers. With occasional quality and service problems, Robyn felt the quality of Olson's products was not as high as that of the other ties suppli- ers. Olson's prices for certain parts were twice as high as prices for imported parts. But deliveries were Robyn's major area of concern with this supplier. Even with a six-to-eight-month lead time, deliveries were unreliable and Robyn had to chase cvery order. She believed Olson had capacity problems although they did not wish to admit it. PLASTIC CABLE CLIPS The old washing machine used about 20 different plas- tic cable tics for a total of about 250 tics in cach ma- chine. At the moment, the laundry division bought nearly $1,250,000 a year worth of plastic cable ties: about EXHIBIT 1 Quotation Request Letter Sample 5 July Dear Sir, The following new parts are required, commencing next March. Please advise price, mini- mum quantity, and delivery details. Part 816549 916553 817709 817803 817923 817975 Description Clip snap.125M X.5 Clip snap 250M X 75 Clip-tie HM FT Clip-lock HBX Clip-tie HM FT (SS) Clip-tie HM RS.2 Qty/Annum 30,000 30,000 60,000 165,000 650,000 135,000 Samples would be appreciated when possible Awaiting your reply with interest Yours faithfully, FISHER & PAYKEL LIMITED R.H. Pemberton (Mrs.) Purchasing Officer Laundry Division However, Olson enjoyed government protection in the sense that, under normal circumstances, a New Zealand agent could not import products that could be made domestically. Barry Cleaver had been supplying F&P with Japanese rivets and cable ties until Olson complained to Trade and Industry. As a result, Barry Cleaver not only had to stop importing and start purchasing from Olson at three times the former price, but he was also having a terrible time meeting F&P volume requirements and had to deliver some of the parts on a daily basis. After F&P started no- ticing that the rivets purchased from Barry Cleaver came in Olson's boxes, Robyn asked Olson for quotes on the rivets, but was subsequently surprised to discover that Olson's prices were dearer than Barry Cleaver's. BARRY CLEAVER AND SONS Barry Cleaver and Sons, a New Zealand agent for three gen- crations with an excellent reputation, was receiving about $2 million a year worth of orders from F&P. Its prices and service were normally excellent. Delivery was good provid- ing adequate lead time of six to eight months was given. Barry Cleaver was getting F&P plastic parts from Japan and, during seller's markets, would have difficulty obtaining supply because of the relative low importance of its orders. However, Robyn was concerned about the long-term availability of the imported parts because the agent's license could be revoked if it was proven that a domestic supply alternative existed. F&P was legally free to buy from any agent in New Zealand. It was up to the agent to justify its stance with the Department of Trade and Indus- try. However, Robyn was well aware of the department's licensing policy (see Exhibit 2), because she remembered vividly a problem encountered with plastic riycts and a few cable ties in May. G. T. ROLLMAN G. T. Rollman was a large New Zealand agent importing from Australia. Although the prices were high, the service was excellent and the delivery was good. The average lead time was three to four months but, in urgent situations, it could supply within six weeks by airfreighting the stock. Robyn Pemberton was also conscious of the advantage of Australian sourcing due to the Closer Economic Rela- tions Agreement between New Zealand and Australia. She knew that a higher New Zealand and Australian content in the new washing machine would permit F&P free of minimum duty access to the Australian market. Although EXHIBIT 2 New Zealand Government Standard Licensing Policy The following policy applies to all item codes except those for which specific policies are set on the following pages 1. Goods of Types Not Produced in New Zealand Licenses will generally be granted to meet reasonable requirements for goods of types not produced in New Zealand, Licenses will not be issued under this provision unless it is quite clear that the goods to be imported are not substitutable for domestic alternatives. The applicants will need to provide adequate evidence that suitable alternatives are not available from New Zealand manufacturers. In considering applications Trade and Industry will assess the extent to which estab- lished licensing provisions have been and are being used to import the goods con- cerned. The aim of this is to ensure that domestic production is not detrimentally af- fected by the consequential availability of license to import directly competitive goods. 2. All Other Goods Licenses may be granted in special circumstances such as: Established trading patterns arising from continuing special licensing provision Shortfalls in normal domestic supply Special provision for the requirements of new manufacturers. Applications under general policies and provisions set out in Annex III. Note: Item Codes which fall under Industry Development Plans are subject to any special import licensing provisions of those plans. This policy does not apply to Australian-made products, she had to inform the costing department of the country of origin of each part purchased, she did not know at what level some price reduction on a part would offset a duty increase. She had tried to find out more information on this subject, but no one had been very explicit. With the labour government in power, a considerable amount of uncer- tainty existed. All she knew was that the group purchasing department of F&P was pushing for as much New Zealand and Australian content as possible. PLASTIC DISTRIBUTING Plastic Distributing was a local agent with annual sales under $1 million that imported plastic products from a number of countries. This young company was eager to obtain orders but offered little technical backup. In the past, Robyn had given it the odd order, especially when supply was tight. She had asked this agent to quote on the new plastic clips mostly for comparison purposes. quotes). In mid-September Robyn called Barry Cleaver and asked for a meeting Barry Cleaver came with a technical expert to meet with Robyn and her supervisor, John Wardrop. Barry made clear that the recent problem encountered with the supply of rivets and cable ties was in the process of being solved, because they had been able to regain their importing license from Trade and Industry by proving that Olson did not have sufficient capacity to meet the demand. Barry Cleaver assured Robyn and John that he felt there would be no problem to import all the new plastic clips required for the new washing machines. Robyn was wondering what to do. In light of Deming's philosophy adopted by Fisher & Paykel as a whole, she felt some pressure toward single sourcing. However, she was not convinced of the soundness of single sourcing in the context of this purchase. She was also wondering to what extent Olson Plastics realized what their situation would be once the old washing machine was phased out should she choose to go with Barry Cleaver. She was debating whether she should call on Olson for further consultation. In any event, she knew a decision had to be roached quickly i viow of the lead time involved with the first production run scheduled for next April SELECTION DECISION Quotes started arriving on July 10 with Barry Cleaver's response. But it was not until Beptember 12 that sho obtained Olson's prices (see Exhibit 3 for a summary of EXHIBIT 3 Summary of Quotes/Prices Part No Barry Cleaver 76.00 Olson Plastic Dist. Rollman per 1,000 816549 54.00 99.95 816553 76.00 119.80 99.95 817709 Description Clip snap 1.25M X.5 Clip snap 250M X .75 Clip-tie HM FT Clip-lock HBX Clip-tie HM FT(SS) Clip-tie HM RS2 25.20 36.80 28.26 134.40 817803 817923 39.20 23.06 61.82 20.40 28.12 817975 38.40 50.00 63.22 BASIC ISSUES 1. Single versus multiple sourcing. 2. Domestic versus international sourcing. 3. Weighting of past performance. 4. Application of Deming's philosophy to purchasing. 5. Political considerations in sourcing. 6. The use of middlemen versus buying direct. STUDENT ASSIGNMENT-Questions 1. If you were in the position of Robyn Pemberton, would you use a single source for plastic cable clips? Why? Why not? Explain 2. What supplier(s) would you choose for plastic cable clips and why? 3. How does the Deming philosophy apply to this particular decision? 4. What has really happened to plastic clip purchases at the Laundry Division? 5. How important is local content in this purchase? 6. Does splitting this order make sense? 7. What role does Barry Cleaver play in this market? 8. What story do the figures tell? 9. What is your assessment of the alternatives here? 10. What kind of contract would you like to have for plastic cable clips

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock