Question: CASE STUDY ASSIGNMENT Piccadilly Hardware in a large distributor of tools and building supplies to major home renovation retailers like Home Hardware and Lowes. It

CASE STUDY ASSIGNMENT

Piccadilly Hardware in a large distributor of tools and building supplies to major home renovation retailers like Home Hardware and Lowes. It has a 45-door warehouse located in Niagara Falls Canada. Its strategic location close to the US border allows the warehouse to serve parts of Southern Ontario along with upstate New York USA. Recently Piccadilly stores in the USA and Canada have launched complaints regarding the quality of their shipment deliveries. Reasons for their displeasure range from late shipments to incorrect bill of ladings. The operations manager at Piccadilly was alarmed to realize that its major customer was providing her the only information available on shipment quality.

Knowing that she had to improve her quality management processes she decided to collect data on the details of the problems. Implementing quality management tools will be necessary to understand the issues better and take corrective actions. She started with issuing check sheets to each of her drivers. The drivers were required to fill out check sheets for every delivery they made in a 7-week period.

The details of what they recorded for the last 7 weeks of deliveries is provided for your analysis. She added other variables to the sheets to see if there are relationships between these and the quality problems.

| Project Name: | |||||||

| Name of Data Recorder: | |||||||

| Location: | |||||||

| Data Collection Dates: | |||||||

| Defect Types/ Event Occurrence | Weeks | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | |

| Number of shipments | 23 | 31 | 28 | 37 | 35 | 40 | 41 |

| Defect Type/Occurrence | |||||||

| Incorrect Bill of Lading | 2 | 3 | 2 | 3 | 2 | 3 | 2 |

| Quantity shipped wrong | 1 | 1 | 2 | 2 | 2 | 2 | 2 |

| Damaged Product | 1 | 2 | 1 | 3 | 2 | ||

| Late Shipment | 2 | 3 | 2 | 3 | 3 | 3 | 3 |

| Unprofessional Driver | 1 | 1 | 2 | 1 | |||

| Wrong Packaging | 1 | 1 | 2 | ||||

| Employee Turnover | 1 | 2 | 4 | 6 | 6 | 7 | 8 |

| Cross Border Shipments | 12 | 10 | 8 | 8 | 6 | 4 | 4 |

USE THE STUDY AND TABLE ABOVE TO ANSWER THE QUESTIONS

1.Read the case 'Piccadilly'. 2.Analyze the provided check sheet to find facts and patterns in the data. Complete the check sheet by adding totals to the data. |

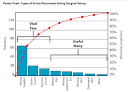

| 3.Using the check sheet data to create a Pareto chart that shows totals for each of the defect types. Also include the accumulated % of the defects. |

| 4.Develop 2 scatter plot diagrams that would show a relationship between the number of defective products per week and another variable that might have an effect on the defect. |

| 5.Draw a fishbone diagram to show the possible underlying causes of the defects when shipping. |

| 6.Highlight the findings of each of your 3 charts. Use the data to draw conclusions surrounding your quality problem. |

| 7.Conduct online research for common quality problems that both shippers and carriers face. |

\f

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts