Question: Case study : Psycho Sports Ltd Peter Townsend knew that he would have to make some decisions pretty soon. His sports goods manufacturing business, Psycho

Case study : Psycho Sports Ltd

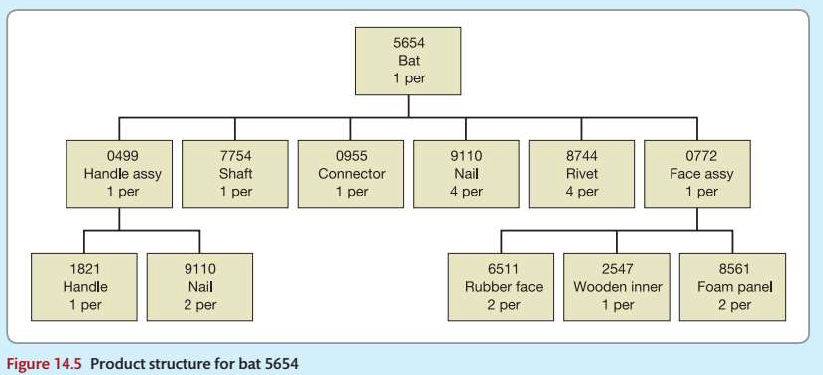

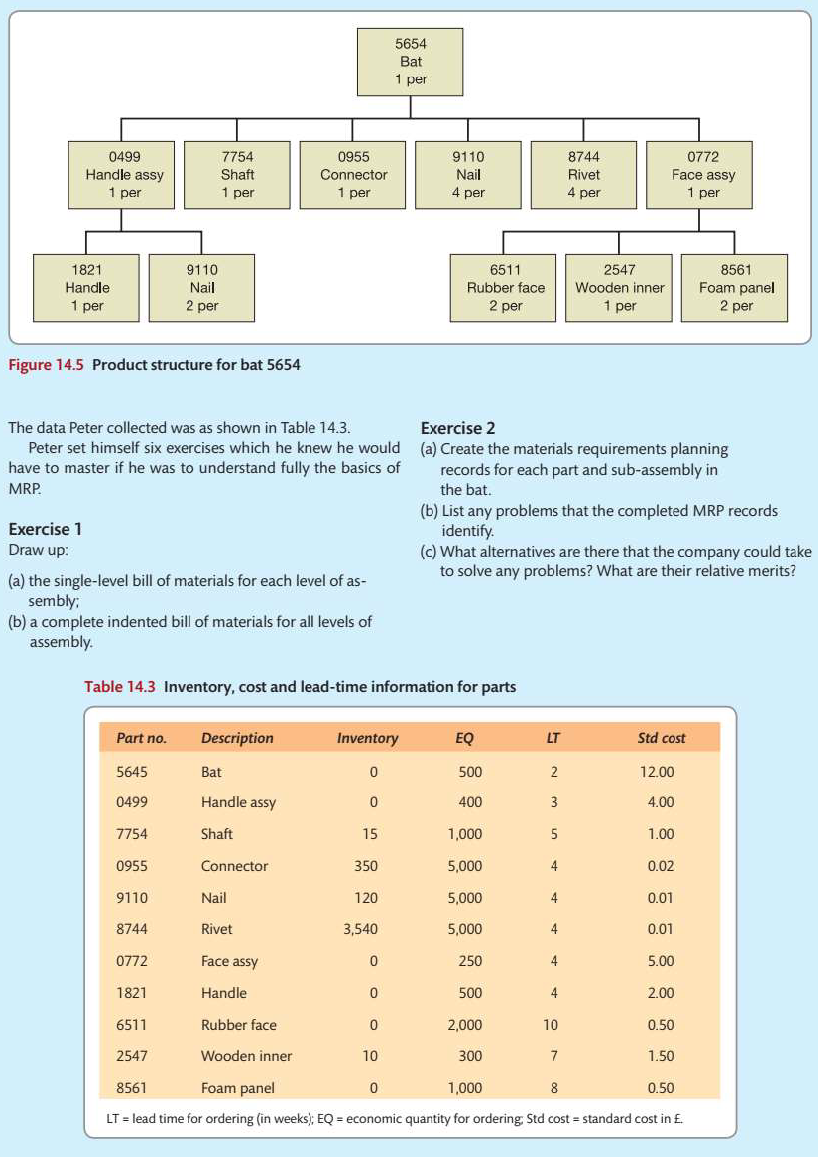

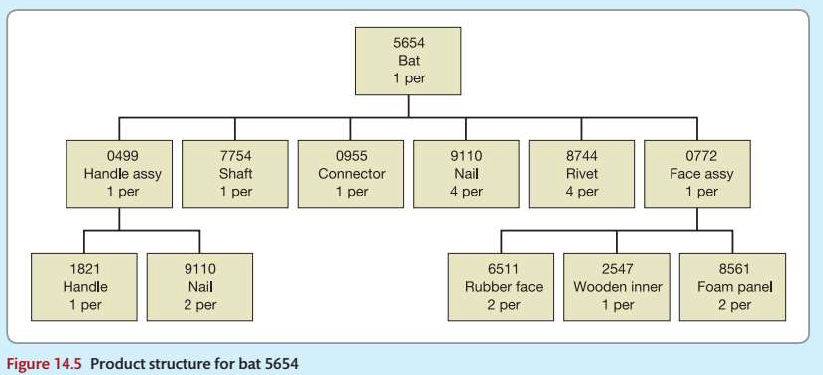

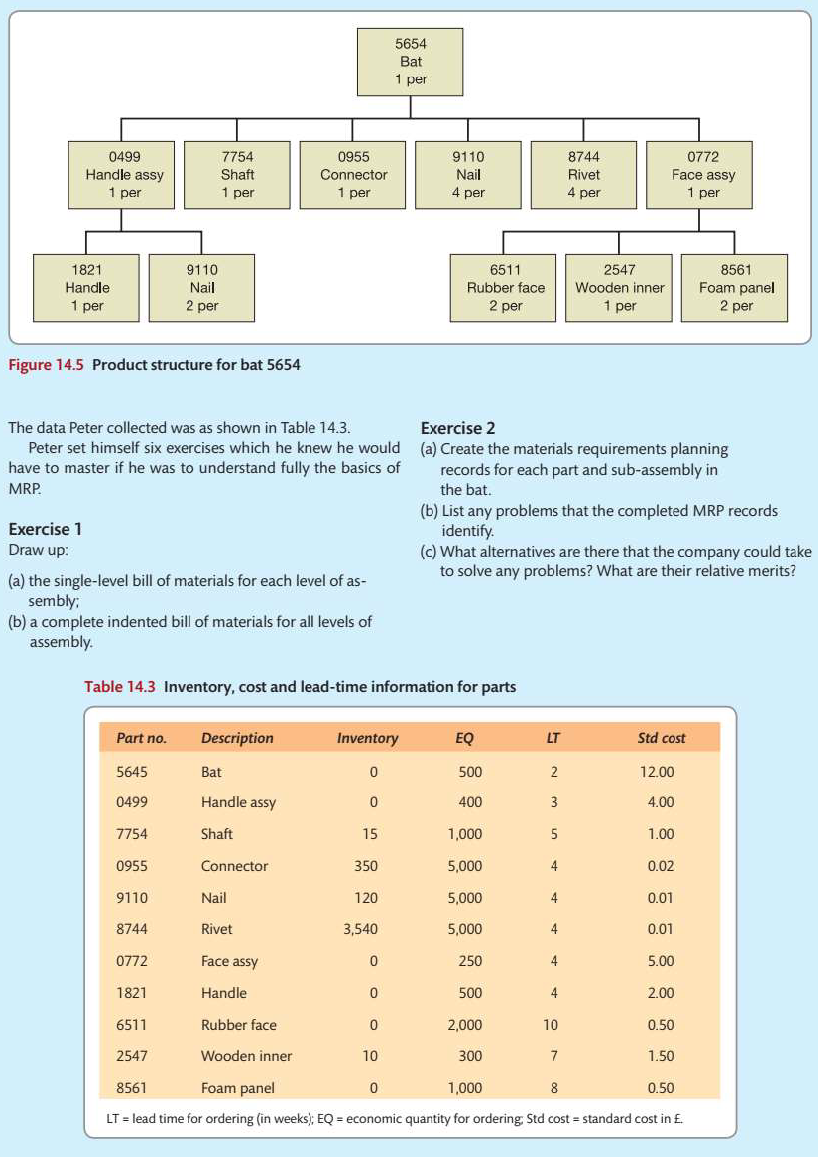

Peter Townsend knew that he would have to make some decisions pretty soon. His sports goods manufacturing business, Psycho sports, had grown so rapidly over the last two years that he would soon have to install some systematic procedures and routines to manage the business. His biggest problem was in manufacturing control. He had started making specialist high-quality table tennis bats but now made a wide range of sports products, including tennis balls, darts and protective equipment for various games. Furthermore, his customers, once limited to specialist sports shops, now included some of the major sports retail chains. We really do have to get control of our manufacturing. I keep getting told that we need what seems to be called an MRP system. I wasnt sure what this meant and so I have bought a specialist production control book from our local bookshop and read all about MRP principles. I must admit, these academics seem to delight in making simple things complicated. And there is so much jargon associated with the technique, I feel more confused now than I did before. Perhaps the best way forward is for me to take a very simple example from my own production unit and see whether I can work things out manually. If I can follow the process through on paper then I will be far better equipped to decide what kind of computer-based system we should get, if any! Peter decided to take as his example one of his new products: a table tennis bat marketed under the name of the high-resolution bat, but known within the manufacturing unit more prosaically as Part number 5654. Figure 14.9 shows the product structure for this table tennis bat, showing the bat made up of two main assemblies: a handle assembly

and a face assembly. in order to bring the two main assemblies together to form the finished bat, various fixings are required, such as nails, connectors, etc. the gross requirements for this particular bat are shown below. the bat is not due to be launched until Week 13 (it is now Week 1), and sales forecasts have been made for the first 23 weeks of sales:

Weeks 1321 inclusive, 100 per

week Weeks 2229 inclusive, 150 per

week Weeks 3035 inclusive, 200 per week

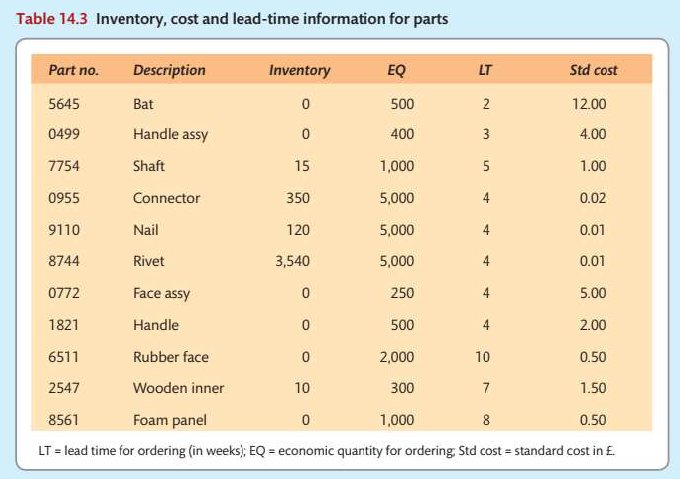

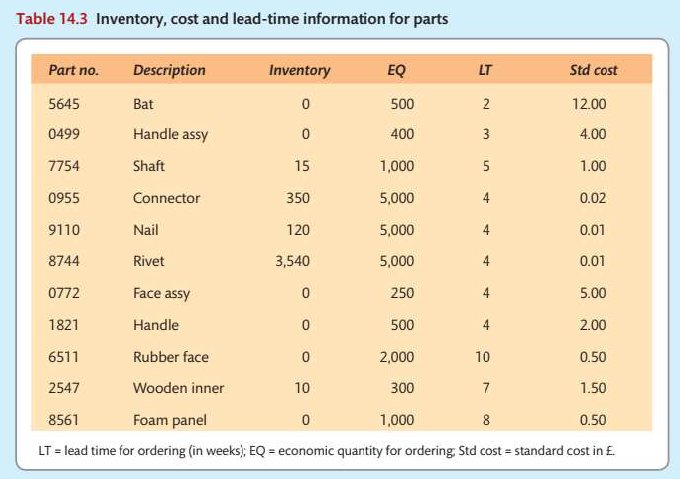

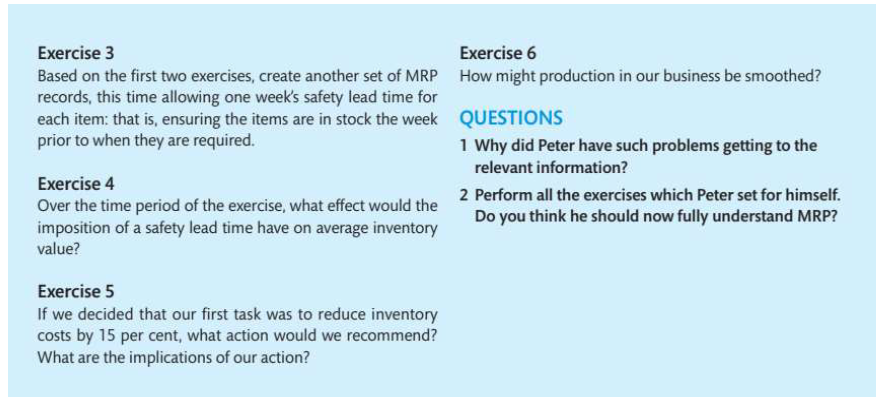

Peter also managed to obtain information on the current inventory levels of each of the parts which made up the finished bat, together with cost data and lead times. He was surprised, however, how long it took him to obtain this information. It has taken me nearly two days to get hold of all the information I need. Different people held it, nowhere was it conveniently put together, and sometimes it was not even written down. To get the inventory data, I actually had to go down to the stores and count how many parts were in the boxes. The data Peter collected was as shown in Table 14.3. Peter set himself six exercises which he knew he would have to master if he was to understand fully the basics of MRP.

Exercise 1

Draw up:

(a) the single-level bill of materials for each level of assembly;

(b) a complete indented bill of materials for all levels of assembly.

Exercise 2

(a) Create the materials requirements planning records for each part and sub-assembly in the bat.

(b) List any problems that the completed MRP records identify.

(c) What alternatives are there that the company could take to solve any problems? What are their relative merits?

Exercise 3

Based on the first two exercises, create another set of MRP records, this time allowing one weeks safety lead time for each item: that is, ensuring the items are in stock the week prior to when they are required.

Exercise 4

Over the time period of the exercise, what effect would the imposition of a safety lead time have on average inventory value?

Exercise 5

If we decided that our first task was to reduce inventory costs by 15 per cent, what action would we recommend? What are the implications of our action?

Exercise 6

How might production in our business be smoothed?

Questions

1) Why did Peter have such problems getting to the relevant information?

2) Perform all the exercises which Peter set for himself. Do you think he should now fully understand MRP

This is the full case study copy. No information left.

This is the full case study copy. No information left.

5654 Bat 1 per 0499 Handle assy 1 per 7754 Shaft 1 per 0955 Connector 1 per 9110 Nail 4 per 8744 Rivet 0772 Face assy 1 per 4 per 1821 Handle 1 per 9110 Nail 2 per 6511 Rubber face 2 per 2547 Wooden inner 1 per 8561 Foam panel 2 per Figure 14.5 Product structure for bat 5654 Table 14.3 Inventory, cost and lead-time information for parts Part no. Description Inventory EQ LT Std cost 5645 0 500 2 12.00 0499 Bat Handle assy Shaft 0 400 3 4.00 7754 15 1,000 5 1.00 0955 Connector 350 5,000 4 0.02 9110 Nail 120 5,000 4 0.01 8744 Rivet 3,540 5,000 4 0.01 0 0 0772 Face assy 250 4 5.00 1821 Handle 500 4 2.00 6511 Rubber face 0 2,000 10 0.50 2547 Wooden inner 10 300 7 1.50 8561 Foam panel 0 1,000 8 0.50 LT = lead time for ordering (in weeks), EQ = economic quantity for ordering Std cost = standard cost in . CASE STUDY Psycho Sports Ltd Source: Shutterstock.com/Chen WS Peter Townsend knew that he would have to make some decisions pretty soon. His sports goods manufacturing business, Psycho Sports, had grown so rapidly over the last two years that he would soon have to install some sys- tematic procedures and routines to manage the business. His biggest problem was in man- ufacturing control. He had started off making specialist high-quality table tennis bats but now made a wide range of sports products, including tennis balls, darts and protective equipment for various games. Furthermore, his customers, once limited to specialist sports shops, now included some of the major sports retail chains.'We really do have to get control of our manufacturing. I keep getting told that we need what seems to be called an MRP sys- tem. I wasn't sure what this meant and so I have bought a specialist production control book from our local bookshop and read all about MRP principles. I must The gross requirements for this particular bat are shown admit, these academics seem to delight in making simple below. The bat is not due to be launched until Week 13 (it things complicated. And there is so much jargon associated is now Week 1), and sales forecasts have been made for the with the technique, I feel more confused now than I did before. first 23 weeks of sales: 'Perhaps the best way forward is for me to take a very sim- Weeks 13-21 inclusive, 100 per week ple example from my own production unit and see whether Weeks 22-29 inclusive, 150 per week I can work things out manually. If I can follow the process Weeks 30-35 inclusive, 200 per week. through on paper then I will be far better equipped to decide what kind of computer-based system we should get, if any! Peter also managed to obtain information on the current Peter decided to take as his example one of his new inventory levels of each of the parts which made up the fin- products: a table tennis bat marketed under the name of ished bat, together with cost data and lead times. He was the 'high-resolution' bat, but known within the manufactur- surprised, however, how long it took him to obtain this ing unit more prosaically as Part Number 5654. Figure 14.5 information. 'It has taken me nearly two days to get hold of shows the product structure for this table tennis bat, show- all the information I need. Different people held it, nowhere ing the table tennis bat made up of two main assemblies: a was it conveniently put together, and sometimes it was not handle assembly and a face assembly. In order to bring the even written down. To get the inventory data, I actually had two main assemblies together to form the finished bat, vari- to go down to the stores and count how many parts were in ous fixings are required, such as nails, connectors, etc. the boxes.' 5654 Bat 1 per 0499 0772 7754 Shaft 1 per Handle assy 1 per 0955 Connector 1 per 9110 Nail 8744 Rivet 4 per Face assy 1 per 4 per 1821 Handle 1 per 9110 Nail 2 per 6511 Rubber face 2 per 2547 Wooden inner 1 per 8561 Foam panel 2 per Figure 14.5 Product structure for bat 5654 The data Peter collected was as shown in Table 14.3. Exercise 2 Peter set himself six exercises which he knew he would (a) Create the materials requirements planning have to master if he was to understand fully the basics of records for each part and sub-assembly in MRP. the bat. (b) List any problems that the completed MRP records Exercise 1 identify Draw up: (c) What alternatives are there that the company could take to solve any problems? What are their relative merits? (a) the single-level bill of materials for each level of as- sembly: (b) a complete indented bill of materials for all levels of assembly Table 14.3 Inventory, cost and lead-time information for parts Part no. Description Inventory EQ LT Std cost 5645 Bat 0 500 2 12.00 0499 Handle assy 0 400 3 4.00 7754 Shaft 15 1,000 5 1.00 0955 Connector 350 5,000 4 0.02 9110 Nail 120 5,000 4 0.01 8744 Rivet 3,540 5,000 4 0.01 0772 Face assy 0 250 4 5.00 1821 Handle 0 500 4 2.00 6511 Rubber face 0 2,000 10 0.50 2547 Wooden inner 10 300 7 1.50 8561 Foam panel 0 1,000 8 0.50 LT = lead time for ordering (in weeksEQ = economic quantity for ordering Std cost = standard cost in . Exercise 3 Exercise 6 Based on the first two exercises, create another set of MRP How might production in our business be smoothed? records, this time allowing one week's safety lead time for each item: that is, ensuring the items are in stock the week QUESTIONS prior to when they are required. 1 Why did Peter have such problems getting to the relevant information? Exercise 4 Over the time period of the exercise, what effect would the 2 Perform all the exercises which Peter set for himself. Do you think he should now fully understand MRP? imposition of a safety lead time have on average inventory value? Exercise 5 If we decided that our first task was to reduce inventory costs by 15 per cent, what action would we recommend? What are the implications of our action

This is the full case study copy. No information left.

This is the full case study copy. No information left.