Question: Case Study: Quality Management The following case study emphasizes the quality aspects of Lean Six including the dimensions of quality, developing an in-process quality cost

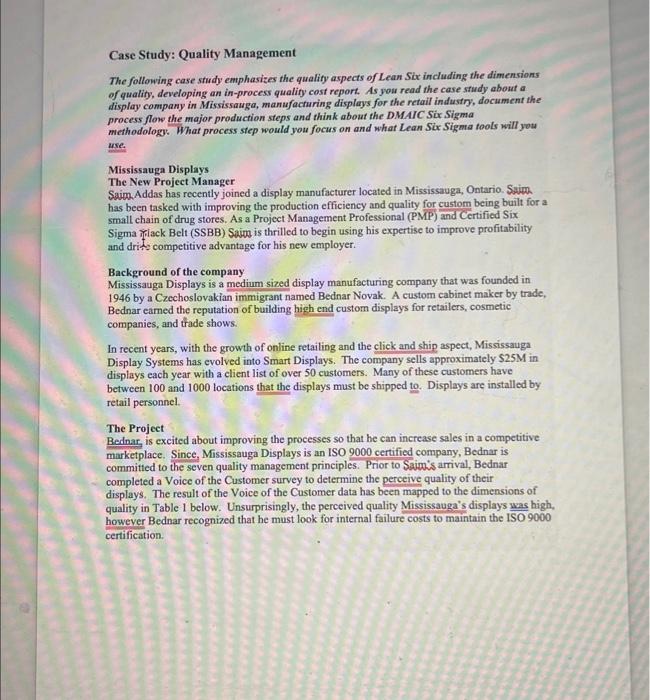

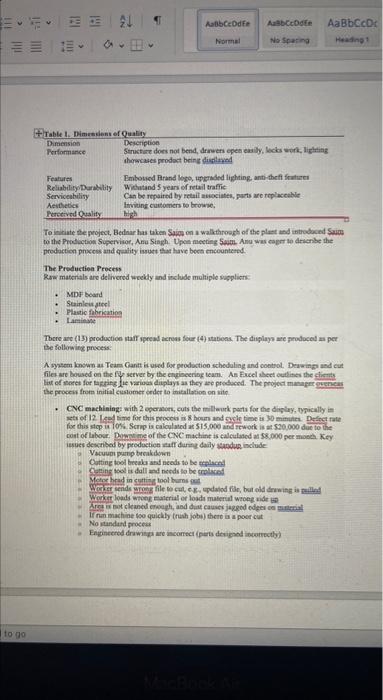

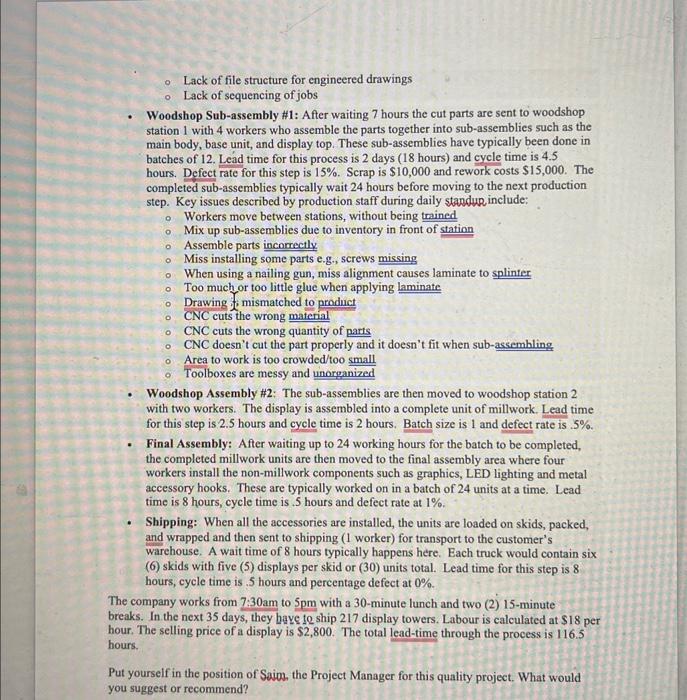

Case Study: Quality Management The following case study emphasizes the quality aspects of Lean Six including the dimensions of quality, developing an in-process quality cost report. As you read the case study about a display company in Mississauga, manufacturing displays for the retail industry, document the process flow the major production steps and think about the DMAIC Six Sigma methodology. What process step would you focus on and what Lean Six Sigma tools will you use Mississauga Displays The New Project Manager Saim.Addas has recently joined a display manufacturer located in Mississauga, Ontario. Ssim has been tasked with improving the production efficiency and quality for custom being built for a small chain of drug stores. As a Project Management Professional (PMP) and Certified Six Sigma rfiack Belt (SSBB) Saim is thrilled to begin using his expertise to improve profitability and drits competitive advantage for his new employer. Background of the company Mississauga Displays is a medium sized display manufacturing company that was founded in 1946 by a Czechoslovakian immigrant named Bednar Novak. A custom cabinet maker by trade, Bednar eamed the reputation of building high end custom displays for retailers, cosmetic companies, and trade shows. In recent years, with the growth of online retailing and the click and ship aspect, Mississauga Display Systems has evolved into Smart Displays. The company sells approximately $25M in displays each year with a client list of over 50 customers. Many of these customers have between 100 and 1000 locations that the displays must be shipped to. Displays are installed by retail personnel. The Project Bednar, is excited about improving the processes so that he can increase sales in a competitive marketplace. Since, Mississauga Displays is an ISO 9000 certified company, Bednar is committed to the seven quality management principles. Prior to Saim's arrival, Bednar completed a Voice of the Customer survey to determine the perceive quality of their displays. The result of the Voice of the Customer data has been mapped to the dimensions of quality in Table 1 below. Unsurprisingly, the perceived quality Mississauga's displays was high, however Bednar recognized that he must look for internal failure costs to maintain the 1SO 9000 certification. The Preduction Process Raw materals are delivered weekly and inchude multiple sugplisth: + MDI beart - Seinlens ateel - Platic fibricatiog - Larminge There arc (13) production itaff speed acruas four (4) atabens. The dipglays aee produced a per the tolleming process: A syztem kown at Team Gant is verd ber peoduction schedaliag and cootrol. Deawing and cut files are boused on the fIY server by the enpineering team. An Eucel abeet cellines the clicrint lith of neses for tagring lie varibus dipplays as they are predeced. The project managme orencas the process frem inifial cishomer ocder to inicallotion on wite - CVC machinings with 2 eperanort, cuts the millaurk parts for the dipliny, tyoucally i= sets of 12 . 1 ced lime for this peoces is 8 houn and sycle time is 30 mimunter Defoct rate fior this stop is 105 . Scmp is calculated ar 515,000 afic Frwork is at 520,000 due to the cont of labour. Dowrtime of the CNC mactine is calculased at 58.000 per moech Keyy issues descriped by prodectien anft durat daily asaduR inchude Vacuupt panp breakdown Cutting tool teeck arst needs to be teplacet Gething sod is dall and necds to be irplices Metrer hrad in cutting tool hums ont Wosker loads wicen elaterial of losdl material weoe wide is * Crit a not cleanod erwelh, and dive causes japged ed ces ce minterial * If rem machine too quiclty (ruah jobie) thert a a poor cut 2. No itanderd proceses - Engineered drawitp are incortect (pets deviged ictarwectly) - Lack of file structure for engineered drawings Lack of sequencing of jobs - Woodshop Sub-assembly \#1: After waiting 7 hours the cut parts are sent to woodshop station 1 with 4 workers who assemble the parts together into sub-assemblics such as the main body, base unit, and display top. These sub-assemblies have typically been done in batches of 12. Lead time for this process is 2 days ( 18 hours) and cycle time is 4.5 hours. Defect rate for this step is 15%. Scrap is $10,000 and rework costs $15,000. The completed sub-assemblies typically wait 24 hours before moving to the next production step. Key issues described by production staff during daily standup include: - Workers move between stations, without being tmined. - Mix up sub-assemblies due to inventory in front of station - Assemble parts incorrectly - Miss installing some parts e.g., screws missing - When using a nailing gun, miss alignment causes laminate to splinter - Too much or too little glue when applying laminate - Drawing + mismatched to product - CNC cuts the wrong material - CNC cuts the wrong quantity of parts - CNC doesn't cut the part properly and it doesn't fit when sub-assembling - Area to work is too crowded/too small - Toolboxes are messy and unorganized 5. Develop a Quality Cost Report for the internal failure costs. 6. Describe which tools will be used to improve the process so that it stays within an acceptable range of defects. 7. What is your preferred solution? Give at least two pros and two cons to your preferred solution

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts