Question: Case Study: Quality Management The following case study emphasizes the quality aspects of Lean Six including the dimensions of quallits, developing an in-process quality cost

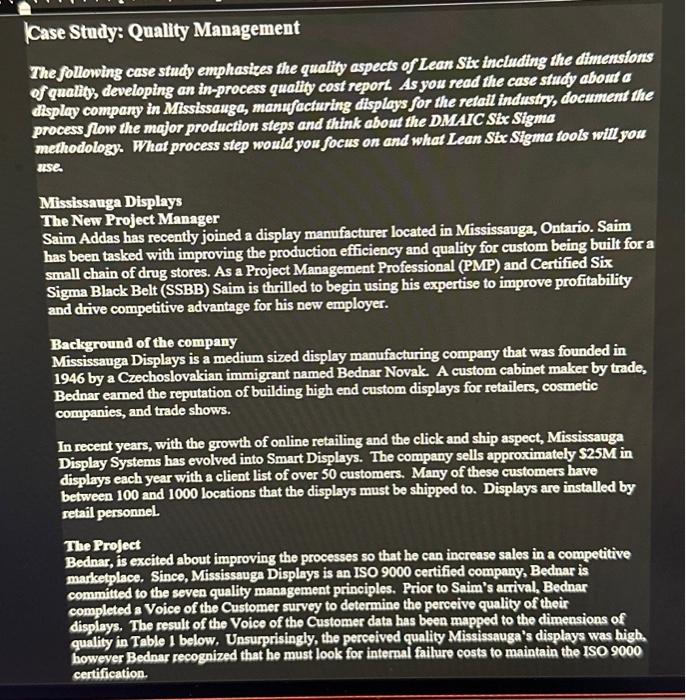

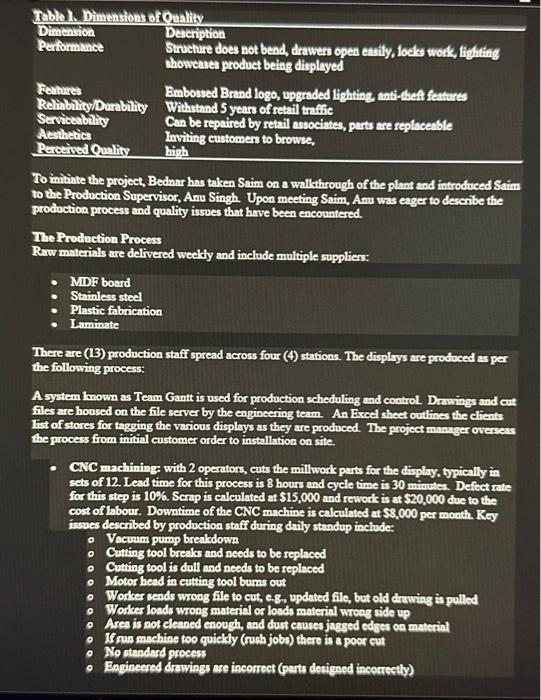

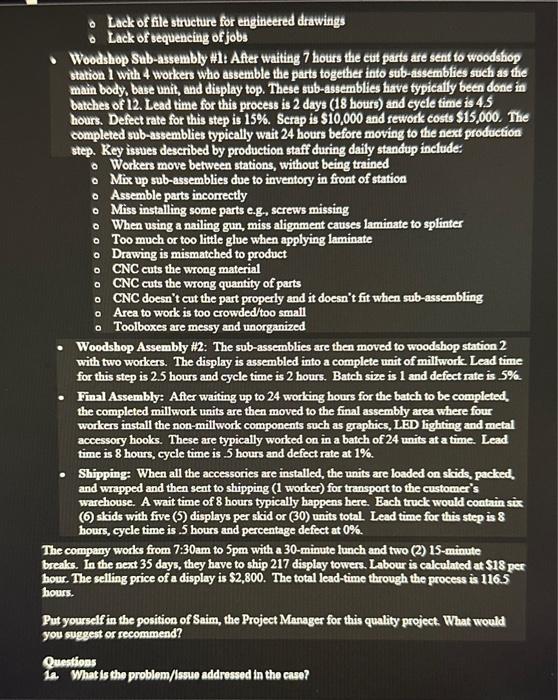

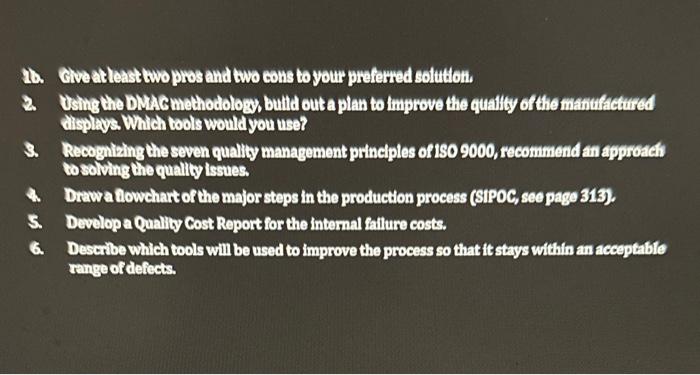

Case Study: Quality Management The following case study emphasizes the quality aspects of Lean Six including the dimensions of quallits, developing an in-process quality cost report. As you read the case study about a displey company in Mississauga, manufacturing disploys for the retatl industry, document the process flow the major production steps and think about the DMAIC Six Sigma methodologg. What process step womid you focus on and what Lean Stx Stgme toots will you use. Mississauga Displays The New Project Manager Saim Addas has recently joined a display manufacturer located in Mississauga, Ontario. Saim has been tasked with improving the production efficiency and quality for custom being built for a small chain of drug stores. As a Project Management Professional (PMP) and Certified Six Sigma Black Belt (SSBB) Saim is thrilled to begin using his expertise to improve profitability and drive competitive advantage for his new employer. Background of the company Mississauga Displays is a medium sized display manufacturing company that was founded in 1946 by a Czechoslovakian immigrant named Bednar Novak. A custom cabinet maker by trade, Bednar eamed the reputation of building high end custom displays for retailers, cosmetic companies, and trade shows. In recent years, with the growth of online retailing and the click and ship aspect, Mississauga Display Systems has evolved into Smart Displays. The company sells approximately S25M in displays each year with a client list of over 50 customers. Many of these customers have between 100 and 1000 locations that the displays must be shipped to. Displays are installed by retail personnel. The Rrolect Bednar, is excited about improving the processes so that he can increase sales in a competitive marketplace. Since, Mississauga Displays is an ISO 9000 certified company, Bednar is committed to the seven quality management principles. Prior to Saim's arrival, Bednar completed a Voice of the Customer survey to determine the perceive quality of their displays. The result of the Voice of the Customer data has been mapped to the dimensions of quality in Table 1 below. Unsurprisingly, the perceived quality Mississauga's displays was high, howeyer Bednar recognized that he must look for internal failure costs to maintain the ISO 9000 certification. Teble 1. Dimensions of Ouality thoweates product being displayed Reahures Embossed Brand logo, upgraded lighting, anti-feft features Relibbility/Durability Withstand 5 years of retail trafice ServiceabilityAestheticsReroervedOualivyCanberepairedbyretailassoclavitingcustomerstobrowse,high To initiate the project, Bednar has taken Saim on a wallthrough of the plant and introduced Saim to the Production Supervisor, Amu Singh. Upon meeting Saim, Anu was eager to deseribe the production process and quality issues that have been encountered. The Prodiction Process Row materials are delivered weekly and include multiple suppliers: - MDF board - Stainless steel - Plastic fabrication - Laminate There are (13) production staff spread across four (4) stations. The displays are produced as per the following process: A system known as Team Gantt is used for production scheduling and control. Drawings and cut files are housed on the file server by the engineering team. An Excel sheet outlines the clients list of stores for tagging the various displays as they are produced. The project masager overseas the process from initial customer order to installation on site. - CNC machining with 2 operators, cuts the millwork parts for the display, typically in sets of 12 . Lead time for this process is 8 hours and cycle time is 30 minutes. Defect rate for this step is 10%. Scrap is calculated at $15,000 and rewodk is at $20,000 due to the cost of labour. Downtime of the CNC machine is calculated at 58,000 per month. Key isspes described by production staff during daily standup include: - Vacuum pump breakdown - Cutting tool breaks and needs to be replaced - Cutting tool is dull and needs to be replaced - Motor head in cutting tool bums out a Worker sends wrong file to cut, e.g, updated file, but old drawing is pulled - Worker loads wrong material or loads material wrong side op - Area is not cleaned enough, and dust causes jagged edges on material - If rus machine too quickly (rush jobb) there is a poor cut - No standard process - Engineered drawings are incorrect (parts designed incorrectly) - Lack of file struchure for engineered drawings - Lack of sequencing of jobs - Woodshop Sub-assembly A1t After waiting 7 hours the cut parts are sent to woodshop station 1 with 4 workers who assemble the parts together into sub-assemblies such as the main body, base unit, and display top. These sub-assemblies have typicatly been done in batches of 12 . Lead time for this process is 2 days ( 18 hours) and cyele time is 4.5 hours. Defect rate for this step is 15%. Scrap is $10,000 and rework costs $15,000. The completed sub-assemblies typically wait 24 hours before moving to the next production step. Key issues described by production staff during daily standup include: - Workers move between stations, without being trained - Mix up sub-assemblies due to inventory in front of station - Assemble parts incorrectly - Miss installing some parts e.g., screws missing - When using a nailing gun, miss alignment causes laminate to splinter - Too moch or too little glue when applying laminate - Drawing is mismatched to product - CNC cuts the wrong material - CNC cuts the wrong quantity of parts - CNC doesn't cut the part properly and it doesn't fit when sub-assembling - Area to work is too crowded/too small - Toolboxes are messy and unorganized - Woodshop Assembly \#2: The sub-assemblies are then moved to woodshop station 2 with two workers. The display is assembled into a complete unit of millwork Lead time for this step is 2.5 hours and cycle time is 2 hours. Batch size is 1 and defect rate is 5%. - Final Assembly: After waiting up to 24 working hours for the batch to be completed, the completed millwork units are then moved to the final assembly area where four workers install the non-millwork components such as graphics, LED lighting and metal accessory hooks. These are typically worked on in a batch of 24 units at a time. Lead time is 8 hours, cycle time is 5 hours and defect rate at 1%. - Shipping: When all the accessories are installed, the units are loaded on skids, packed, and wrapped and then sent to shipping (1 worker) for transport to the customer's warehouse. A wait time of 8 hours typically happens here. Each truck would contain six (6) skids with five (5) displays per skid or (30) units total. Lead time for this step is 8 hours, cycle time is .5 hours and percentage defect at 0%. The company works from 7:30am to 5pm with a 30-minute lunch and two (2) 15 -minute breaks. In the next 35 days, they have to ship 217 display towers. Labour is calculated at $18 per hour. The selling price of a display is $2,800. The total lead-time through the process is 116.5 hours. Put yourself in the position of Saim, the Project Manager for this quality project. What would you suggest or recommend? Questions 12. What is the problom/lssue addressed in the case? Ib. Clveatleast two pros and two cons toyour preferred solution. 2. Using the DMA Gmethodologs, build out a plan to improve the qualty of the manuffictured elispliys. Which tools would you use? 3. Recognizing the soven quality management principles of 1509000 , recommend an approseli tosolving the qually issues. 4. Drew allowchart of the malor steps in the production process (SIPOC, see page 313). 5. Devolop a Quality Cost Report for the internal fallure costs. 6. Describe which tools will be used to improve the process so that it stays withln an acceptable renge of defects

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts