Question: Chapter 12: Scheduling Operations Assignment 3 of 3: How should I schedule my jobs? WS Here's an example to test your skills at creating an

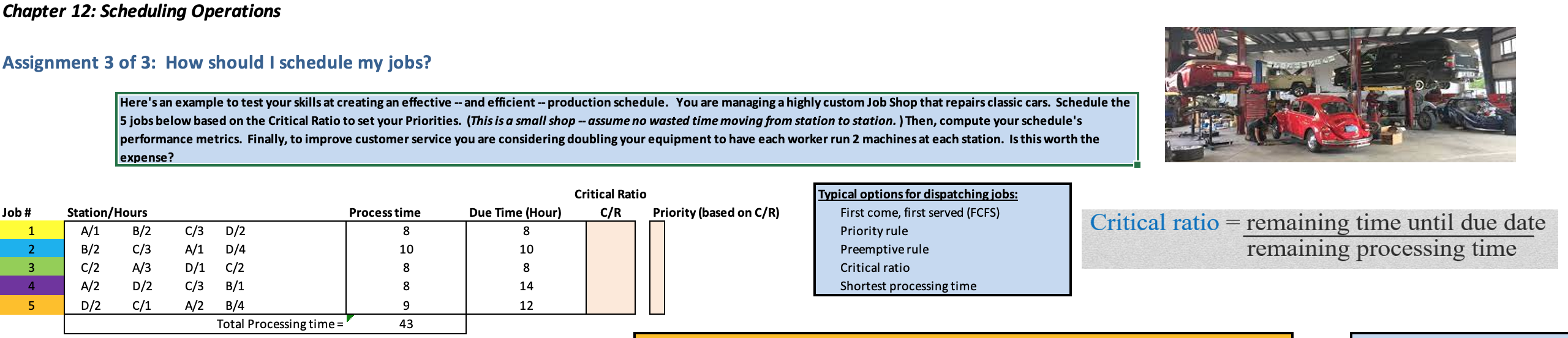

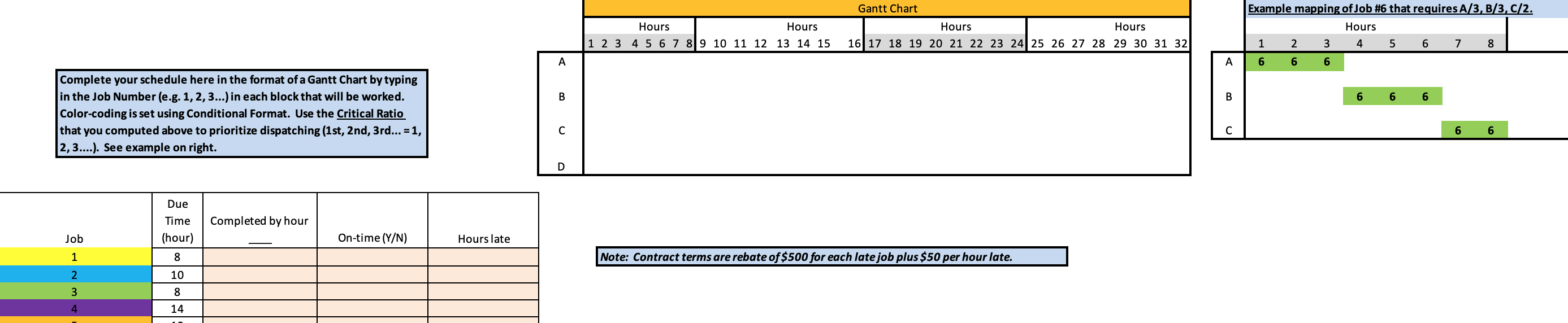

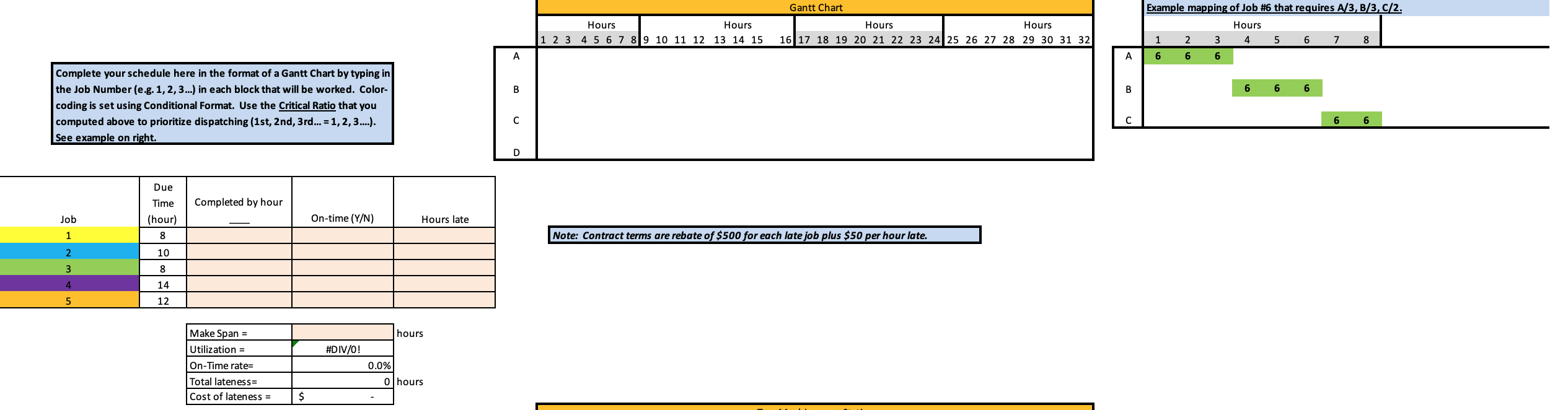

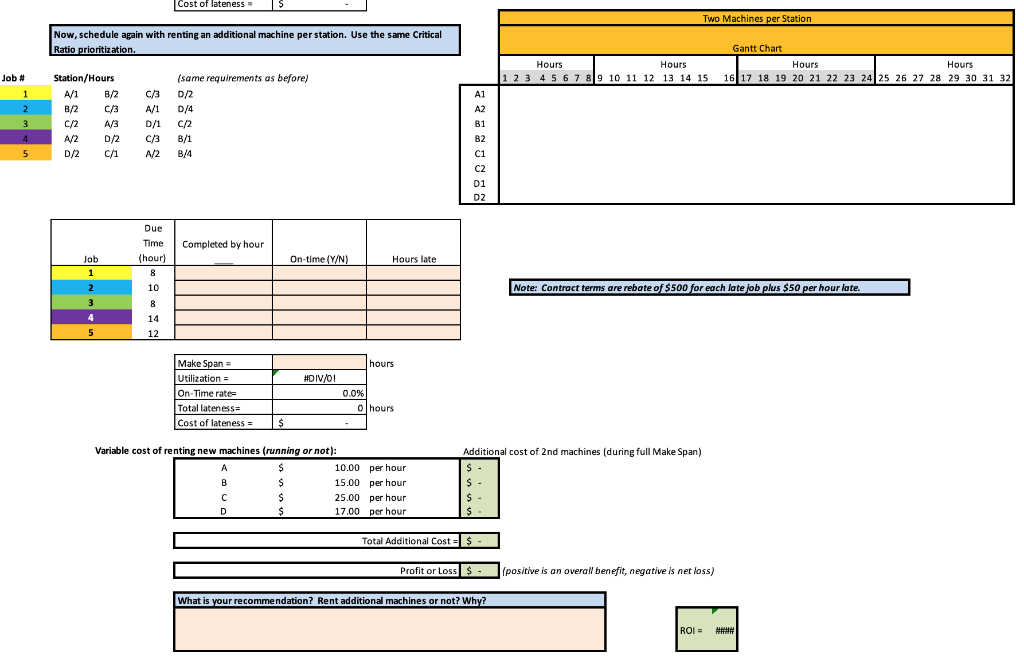

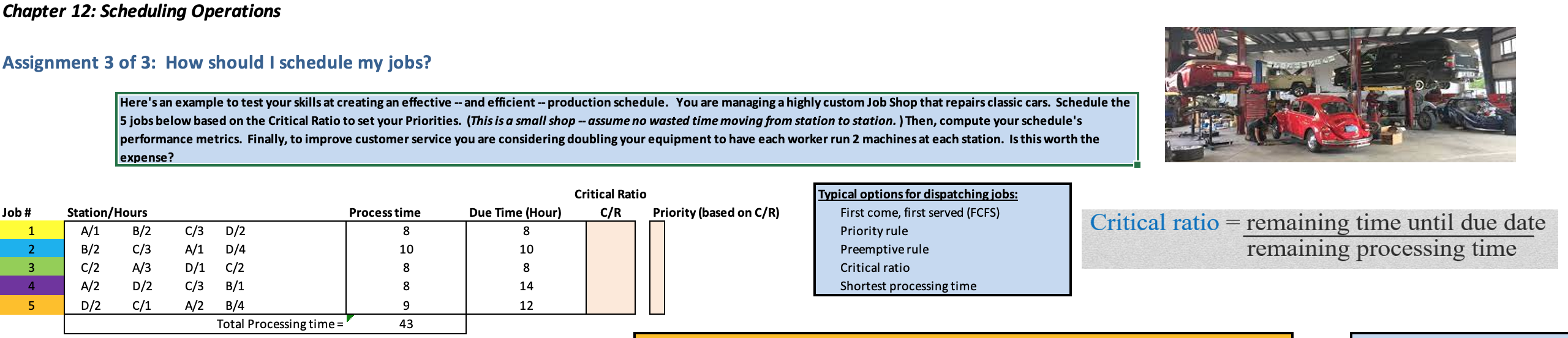

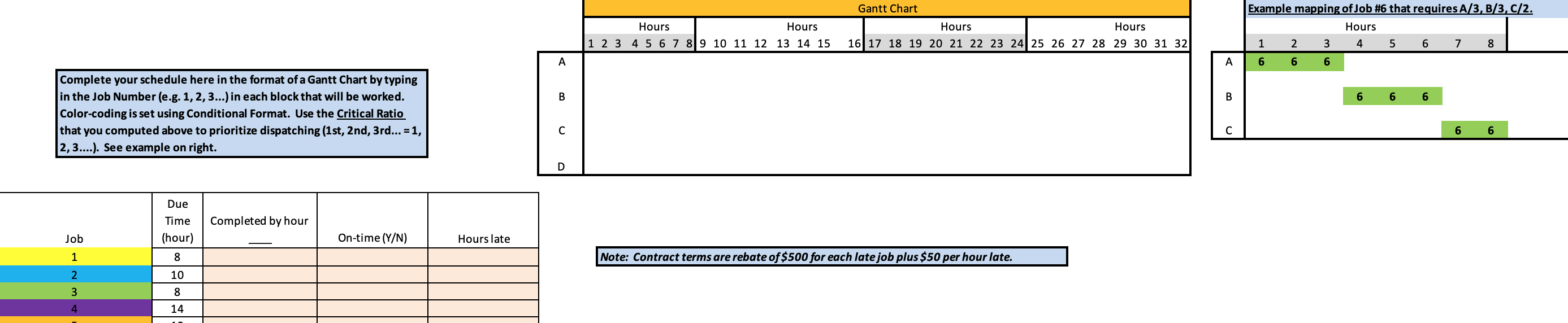

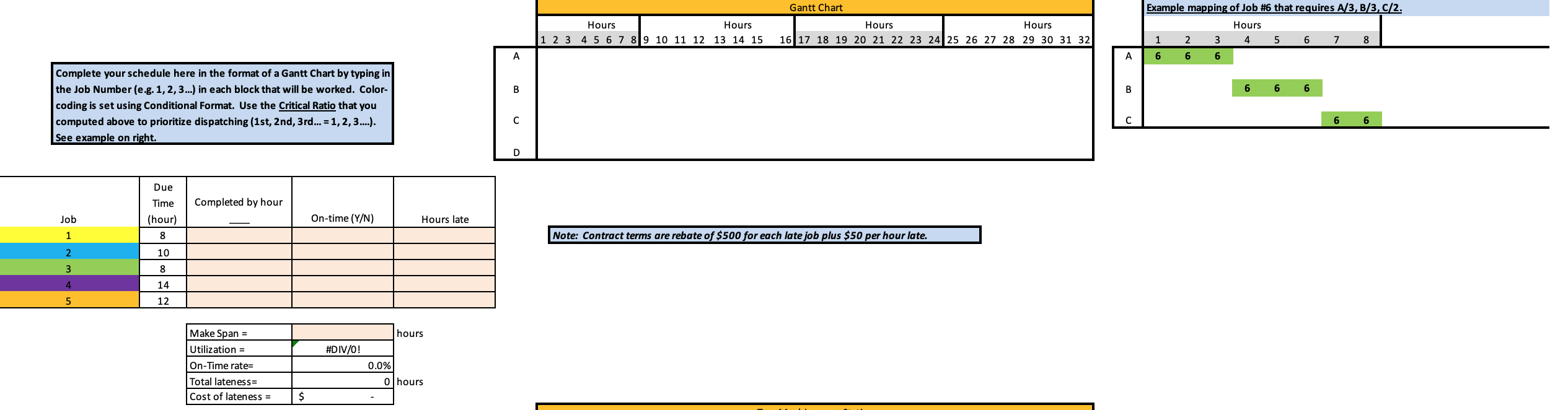

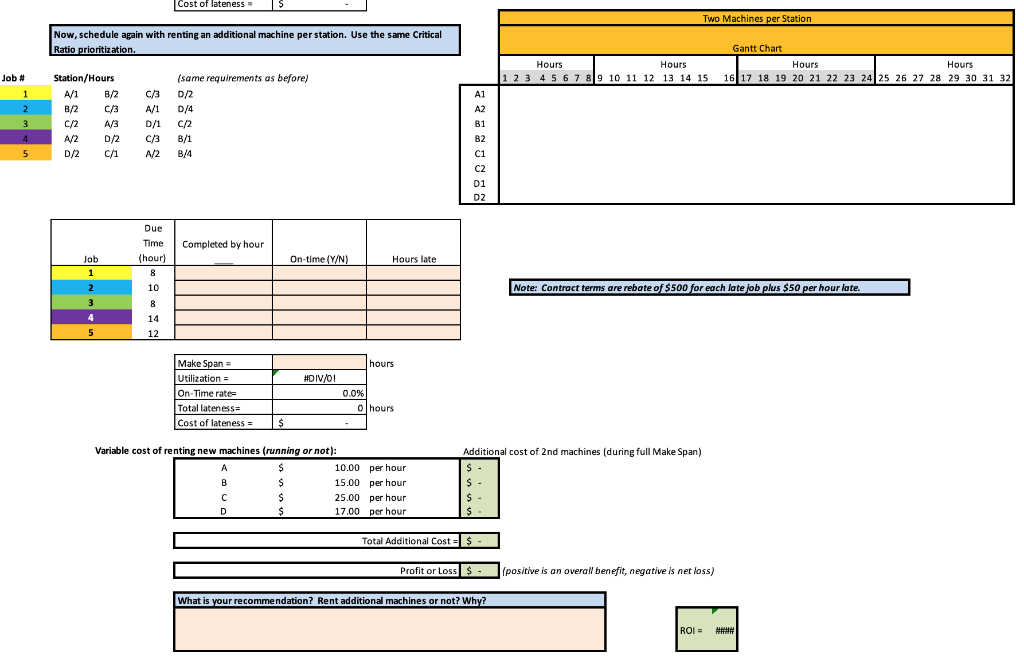

Chapter 12: Scheduling Operations Assignment 3 of 3: How should I schedule my jobs? WS Here's an example to test your skills at creating an effective -- and efficient -- production schedule. You are managing a highly custom Job Shop that repairs classic cars. Schedule the 5 jobs below based on the Critical Ratio to set your Priorities. (This is a small shop -- assume no wasted time moving from station to station. ) Then, compute your schedule's performance metrics. Finally, to improve customer service you are considering doubling your equipment to have each worker run 2 machines at each station. Is this worth the expense? Critical Ratio C/R Process time Priority (based on C/R) Job # 1 Due Time (Hour) 8 A/1 D/2 8 Critical ratio = remaining time until due date remaining processing time 2 Typical options for dispatching jobs: First come, first served (FCFS) Priority rule Preemptive rule Critical ratio Shortest processing time C/3 10 Station/Hours B/2 B/2 C/2 A/3 A/2 D/2 D/2 C/1 10 u w NP C/3 A/1 D/1 C/3 A/2 3 8 8 4 D/4 C/2 B/1 B/4 Total Processing time = 8 14 9 12 43 Hours Hours 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Gantt Chart Hours Hours 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 Example mapping of Job #6 that requires A/3, B/3, C/2. Hours 1 2 3 4 5 6 7 8 A A 6 6 6 B B 6 6 6 Complete your schedule here in the format of a Gantt Chart by typing in the Job Number (e.g. 1, 2, 3...) in each block that will be worked. Color-coding is set using Conditional Format. Use the Critical Ratio that you computed above to prioritize dispatching (1st, 2nd, 3rd... = 1, 2, 3....). See example on right. C 6 6 D Due Time (hour) Completed by hour Job On-time (Y/N) Hours late 1 8 Note: Contract terms are rebate of $500 for each late job plus $50 per hour late. 2. 10 8 3 4 14 Hours Hours 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Gantt Chart Hours Hours 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 Example mapping of Job #6 that requires A/3,B/3, C/2. Hours 1 2 3 4 5 6 7 8 A A 6 6 6 B B 6 6 6 Complete your schedule here in the format of a Gantt Chart by typing in the Job Number (e.g. 1,2,3...) in each block that will be worked. Color- coding is set using Conditional Format. Use the Critical Ratio that you computed above to prioritize dispatching (1st, 2nd, 3rd... = 1, 2, 3 ....). See example on right. C 6 6 D Completed by hour Due Time (hour) 8 Job On-time (Y/N) Hours late 1 Note: Contract terms are rebate of $500 for each late job plus $50 per hour late. 2 10 3 8 4 5 14 12 hours #DIV/0! Make Span = Utilization = On-Time rate= Total lateness Cost of lateness = 0.0% 0 hours $ Cost of lateness Two Machines per Station Now, schedule again with renting an additional machine per station. Use the same Critical Ratio prioritization. Gantt Chart Hours Hours Hours Hours 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 Job # A1 1 2 3 4 5 Station/Hours A/1 B/2 B/2 B C C/3 C/2 A/3 A/2 D/2 D/2 CA1 C/3 A/1 1 D/1 C/3 A/2 (same requirements as before) D/2 D/4 C/2 B/1 B/4 A2 B1 B2 c1 C2 D1 D2 Completed by hour Due Time (hour) 8 8 10 On-time (Y/N) Job 1 1 2 3 Hours late Note: Contract terms are rebate of $500 for each late job plus $50 per hour late. 4 8 14 12 5 hours #DIV/01 Make Span= Utilization = On-Time rates Total lateness Cost of lateness = = 0.0% O hours 0 $ Variable cost of renting new machines (running or not): A $ 10.00 per hour B $ 15.00 per hour C $ 25.00 per hour D $ 17.00 per hour Additional cost of 2nd machines (during full Make Span) $ S- $- $ Total Additional Cost = $. Profit or Loss $. (positive is an overall benefit, negative is net loss) , What is your recommendation? Rent additional machines or not? Why? ROI = #### Chapter 12: Scheduling Operations Assignment 3 of 3: How should I schedule my jobs? WS Here's an example to test your skills at creating an effective -- and efficient -- production schedule. You are managing a highly custom Job Shop that repairs classic cars. Schedule the 5 jobs below based on the Critical Ratio to set your Priorities. (This is a small shop -- assume no wasted time moving from station to station. ) Then, compute your schedule's performance metrics. Finally, to improve customer service you are considering doubling your equipment to have each worker run 2 machines at each station. Is this worth the expense? Critical Ratio C/R Process time Priority (based on C/R) Job # 1 Due Time (Hour) 8 A/1 D/2 8 Critical ratio = remaining time until due date remaining processing time 2 Typical options for dispatching jobs: First come, first served (FCFS) Priority rule Preemptive rule Critical ratio Shortest processing time C/3 10 Station/Hours B/2 B/2 C/2 A/3 A/2 D/2 D/2 C/1 10 u w NP C/3 A/1 D/1 C/3 A/2 3 8 8 4 D/4 C/2 B/1 B/4 Total Processing time = 8 14 9 12 43 Hours Hours 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Gantt Chart Hours Hours 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 Example mapping of Job #6 that requires A/3, B/3, C/2. Hours 1 2 3 4 5 6 7 8 A A 6 6 6 B B 6 6 6 Complete your schedule here in the format of a Gantt Chart by typing in the Job Number (e.g. 1, 2, 3...) in each block that will be worked. Color-coding is set using Conditional Format. Use the Critical Ratio that you computed above to prioritize dispatching (1st, 2nd, 3rd... = 1, 2, 3....). See example on right. C 6 6 D Due Time (hour) Completed by hour Job On-time (Y/N) Hours late 1 8 Note: Contract terms are rebate of $500 for each late job plus $50 per hour late. 2. 10 8 3 4 14 Hours Hours 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Gantt Chart Hours Hours 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 Example mapping of Job #6 that requires A/3,B/3, C/2. Hours 1 2 3 4 5 6 7 8 A A 6 6 6 B B 6 6 6 Complete your schedule here in the format of a Gantt Chart by typing in the Job Number (e.g. 1,2,3...) in each block that will be worked. Color- coding is set using Conditional Format. Use the Critical Ratio that you computed above to prioritize dispatching (1st, 2nd, 3rd... = 1, 2, 3 ....). See example on right. C 6 6 D Completed by hour Due Time (hour) 8 Job On-time (Y/N) Hours late 1 Note: Contract terms are rebate of $500 for each late job plus $50 per hour late. 2 10 3 8 4 5 14 12 hours #DIV/0! Make Span = Utilization = On-Time rate= Total lateness Cost of lateness = 0.0% 0 hours $ Cost of lateness Two Machines per Station Now, schedule again with renting an additional machine per station. Use the same Critical Ratio prioritization. Gantt Chart Hours Hours Hours Hours 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 Job # A1 1 2 3 4 5 Station/Hours A/1 B/2 B/2 B C C/3 C/2 A/3 A/2 D/2 D/2 CA1 C/3 A/1 1 D/1 C/3 A/2 (same requirements as before) D/2 D/4 C/2 B/1 B/4 A2 B1 B2 c1 C2 D1 D2 Completed by hour Due Time (hour) 8 8 10 On-time (Y/N) Job 1 1 2 3 Hours late Note: Contract terms are rebate of $500 for each late job plus $50 per hour late. 4 8 14 12 5 hours #DIV/01 Make Span= Utilization = On-Time rates Total lateness Cost of lateness = = 0.0% O hours 0 $ Variable cost of renting new machines (running or not): A $ 10.00 per hour B $ 15.00 per hour C $ 25.00 per hour D $ 17.00 per hour Additional cost of 2nd machines (during full Make Span) $ S- $- $ Total Additional Cost = $. Profit or Loss $. (positive is an overall benefit, negative is net loss) , What is your recommendation? Rent additional machines or not? Why? ROI = ####