Question: Chemical engineering process design question here are some tips: There are some common small mistakes, such as no purge and leaking compressor when recycle gas,

Chemical engineering process design question here are some tips:

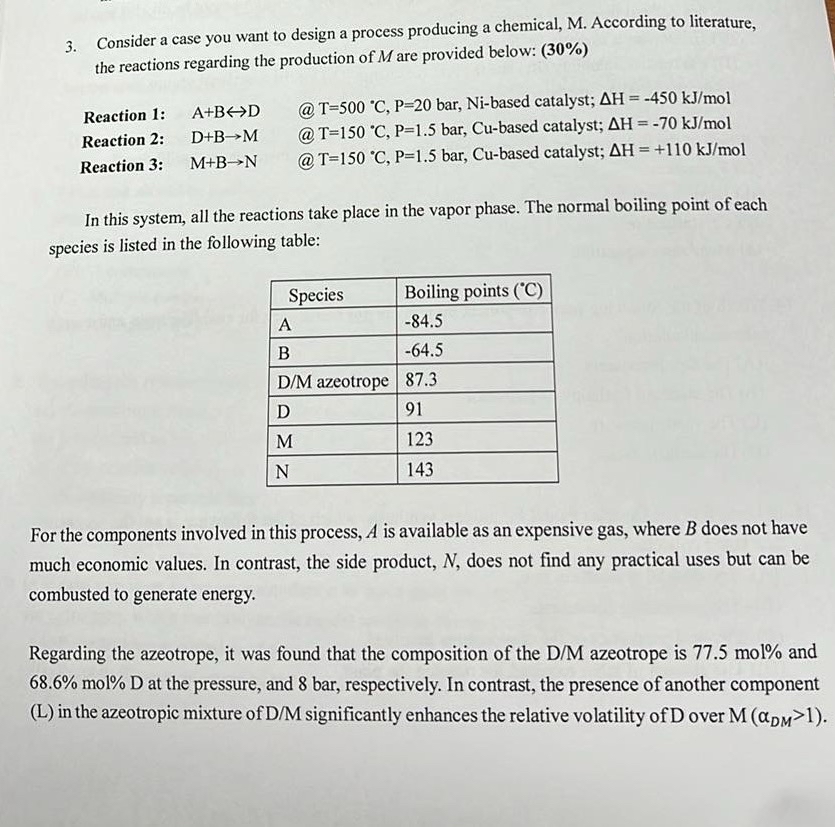

There are some common small mistakes, such as no purge and leaking compressor when recycle gas, the extractive distillation trainer does not feed the material from the top of the tower, is refluxed to the front end of the process actually it should be sent to the burner and then heat energy is obtained heating and cooling There will be some small loss of points if the markings are not clear enough...etc. However, if you make the following mistakes the answer might be wrong:

The two reaction stages are not drawn Gases A and B are separated by cryogenic distillation and are not specified to be separated by azeotropic distillation

Excess B is not designed but it is not mentioned that reflow A is required. Please come up with a reasonable process structure based on the information provided. Also try to specify the equipment that you maybwant to use. Some descriptions that clarify your idea when constructing the process may be helpful. Note that there is no correct answer to this question but a good process configuration should be simple and cost saving.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock