Question: Components for a liquid detergent ( = 10 centipoise) are blended in the pilot plant in 10-gallon, baffled, flat-bottomed tank 10 inches in diameter. A

Components for a liquid detergent ( = 10 centipoise) are blended in the pilot plant in 10-gallon, baffled, flat-bottomed tank 10 inches in diameter. A double-turbine agitator with blades 6 inches in diameter is used. A 1/2 hp motor turns the agitator at 500 rpm for 30 minutes to attain complete dispersion.

In the plant a geometrically similar unit is planned to blend 200-gallon batches of this solution. Determine consistent values of agitator and tank diameter, revolutions per minute, power requirement, and batch time for the plant unit. Base the design on:

a. Constant Reynolds Number b. Constant agitator peripheral speed c. Constant RPM

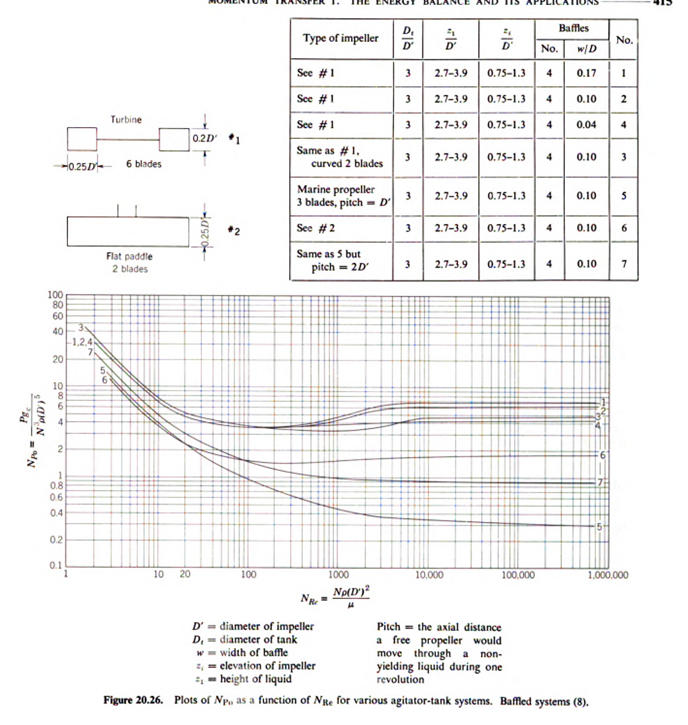

D Baffles Type of impeller D No. D D No. WD 3 2.7-3.9 0.75-1.3 4 See #1 See #1 0.17 0.10 1 2 3 2.7-3.9 0.75-1.3 4 2 Turbine 3 2.7-3.9 0.75-1.3 4 0.04 4 0.2D 1 3 2.7-3.9 0.75-1.3 4 4 0.10 -0.25 6 blades See #1 Same as # 1 curved 2 blades Marine propeller 3 blades, pitch - D See #2 3 2.7-3.9 0.75-1.3 4 0.10 5 2 -0.25D- 3 2.7-3.9 0.75-1.3 4 0.10 6 Same as 5 but Fiat paddle 2 blades 3 2.7-3.9 0.75-1.3 4 pitch - 2D 0.10 7 100 80 60 40 3 -1.2.4 20 10 8 6 4 PS WNUN 2 1 0.8 0.6 04 Oo 02 0.1 10 20 100 10.000 100.000 1,000,000 1000 NRC NPD") D' -diameter of impeller Pitch = the axial distance D. -diameter of tank a free propeller would w = width of baffle move through a non- 2 = elevation of impeller yielding liquid during one 5:- height of liquid revolution Figure 20.26. Plots of Npo as a function of Nne for various agitator-tank systems. Baffled systems (8)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts