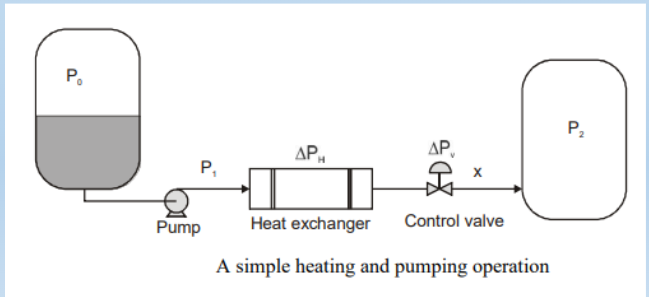

Question: -Consider a heating process (shown below) where liquid with specific gravity 1 is pumped from a feed tank to a final tank. The flow rate

-Consider a heating process (shown below) where liquid with specific gravity 1 is pumped from a feed tank to a final tank. The flow rate at design condition is 100 gpm, the pressure 0 in the tank is atmospheric , the pressure drop over the heat exchanger at the design flow rate is 40 psi, and the pressure in the final tank 2 is 150 psig. The control valve is half open ( () =.) at the design flow. -The process engineer wants to design a system that has a low pressure drop across the control valve. However, the control engineer wants to take a large pressure drop over the valve since the large pressure drop will allow a large range of flow rate through the valve. -The control valve is originally designed to take a 20 psig pressure drop at the design flow rate of 100gpm when the valve is half open. -The pressure drop over the heat exchanger at a given flow rate F is given: =40( /)^2 -Important Assumption: The total pressure drop across the heat exchanger and the valve needs to remain constant. -Part A) What is the maximum possible and minimum possible flow rate through the valve? What is the turndown ratio (the ratio of maximum to minimum flow rate through the valve)?

Part B) We want to stay at the design condition, but we also want the valve experience a range of pressure drops (various pressure drops across the valve). Calculate the valve coefficient and turndown ratios for the control valve at a range of pressure drop from 10 to 100 psi

Thank you

A smmpie neanng and punpur operation

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts