Question: Consider the following distribution system: - Single product. - Two plants, referred to as plant p1 and plant p2. - Plant p2 has an annual

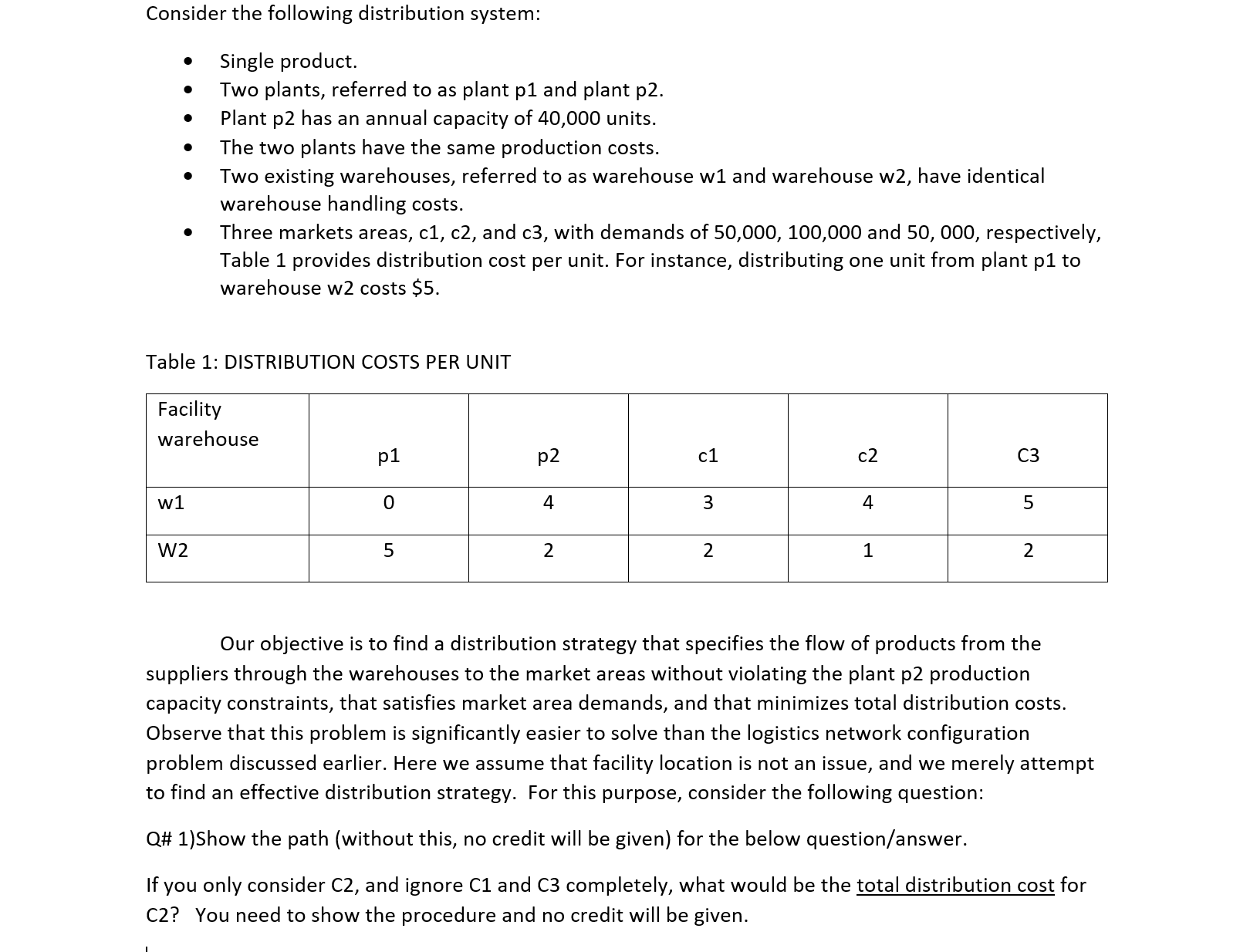

Consider the following distribution system: - Single product. - Two plants, referred to as plant p1 and plant p2. - Plant p2 has an annual capacity of 40,000 units. - The two plants have the same production costs. - Two existing warehouses, referred to as warehouse w1 and warehouse w2, have identical warehouse handling costs. - Three markets areas, c1, c2, and c3, with demands of 50,000, 100,000 and 50, 000, respectively, Table 1 provides distribution cost per unit. For instance, distributing one unit from plant p1 to warehouse w2 costs $5. Table 1: DISTRIBUTION COSTS PER UNIT Our objective is to find a distribution strategy that specifies the flow of products from the suppliers through the warehouses to the market areas without violating the plant p2 production capacity constraints, that satisfies market area demands, and that minimizes total distribution costs. Observe that this problem is significantly easier to solve than the logistics network configuration problem discussed earlier. Here we assume that facility location is not an issue, and we merely attempt to find an effective distribution strategy. For this purpose, consider the following question: Q\# 1)Show the path (without this, no credit will be given) for the below question/answer. If you only consider C2, and ignore C1 and C3 completely, what would be the total distribution cost for C2 ? You need to show the procedure and no credit will be given

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts