Question: Design Project 1: Process Control CNG633 Process Control & Industrial Safety A key aspect of the design and continuous improvement of processes is successful process

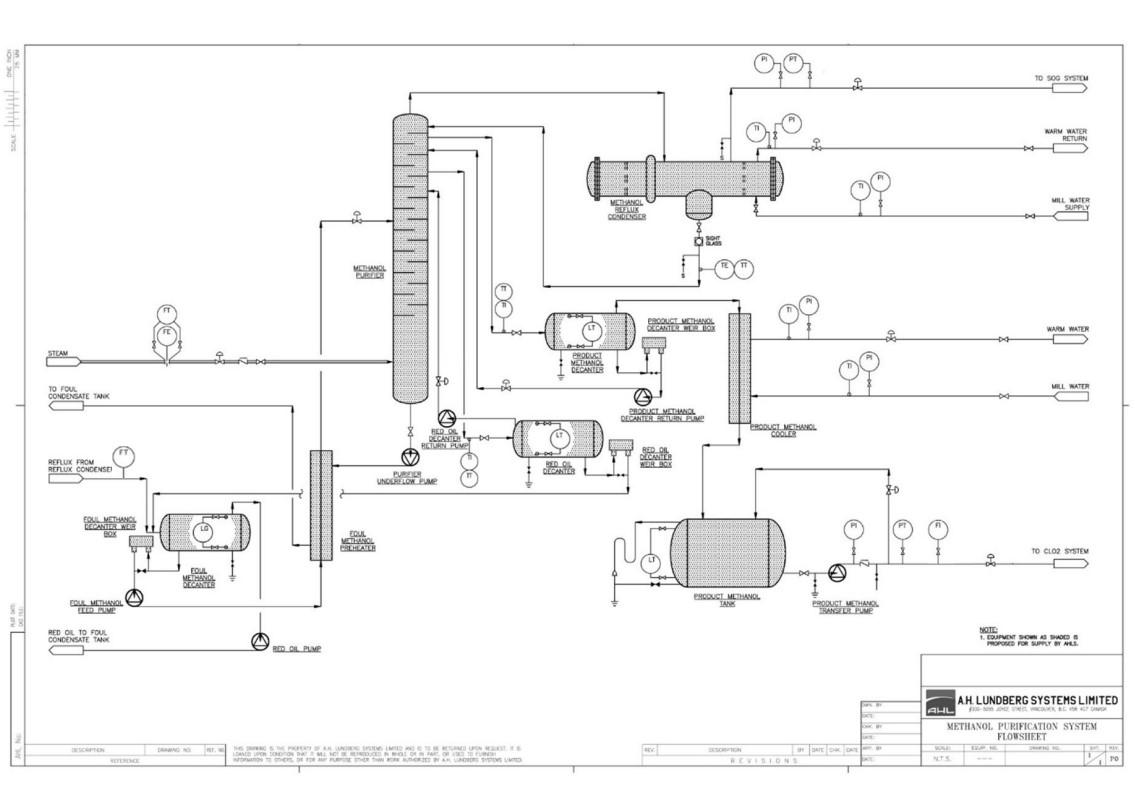

Design Project 1: Process Control CNG633 Process Control & Industrial Safety A key aspect of the design and continuous improvement of processes is successful process control. This requires an engineer and/or technologist to assess critical process variables and design loops to control them within desired limits. In this Project, you will be designing control loops for a real industrial process used for methanol purification as part of a larger plant which produces chlorine dioxide (CIO2). This process converts "foul" methanol (containing impurities such as turpentine) to purified methanol that can be used in the CIO2 production process which follows. A partially-completed P&ID is attached for this purification process. Control System Design The methanol purification process contains several control systems designed to keep it running safely, while producing methanol of the desired purity. In this section, each incomplete control system associated with a transmitter (e.g. TT, LT) shown in the methanol purification plant P&ID is to be designed, as well as the control variables it is using to maintain control of the process. Indicate and label each loop on the P&ID provided. Add the control strategy (dashed line between sensor and instrument) on the P&ID as well. The following must also be listed/described for each control loop: Measured variable Manipulated variable Loop type (open, feedforward, or feedback) Gain type (positive or negative) Suggested control method or sub-type (PI, PID, etc.) . . 10 SOG SYSTEM WARM WATER RETURN . MEANAL CONDENSER MILL WATER SUPPLY Open METANOL CELLE GULMETHANOL CALELOR WARM WATER STEAM PROCUCI METHANOL CECANTE XD VILL WATER TO FOUL CONDENSATE TAMK HOUT NOTAL DECA ILALLINE FEOL RECANTER PRODUCT METHANOL COOLER RERUK FROM REFLUX CONDENS ROL DECIR LEGE DOL DER PU UNGALOWPUM 3-0 EOUL METINGE LEBANTENG BOX TUL METHANOL PREHLAH TO CLO2 SYSTEM EOL METHANOL BECANTER EL METAAL PRODUCT METHANOL TANK PRODUCE METHANOL ELANGOR RED OL TO FOUL CONDENSATE TAI SOTE 1. DUPVET SOHO PROPORED FOR SUPPLY WILL RED OIL PUMP AH. LUNDBERG SYSTEMS LIMITED AHL METHANOL, PURIFICATION SYSTEM FLOWSHEET ON PO Design Project 1: Process Control CNG633 Process Control & Industrial Safety A key aspect of the design and continuous improvement of processes is successful process control. This requires an engineer and/or technologist to assess critical process variables and design loops to control them within desired limits. In this Project, you will be designing control loops for a real industrial process used for methanol purification as part of a larger plant which produces chlorine dioxide (CIO2). This process converts "foul" methanol (containing impurities such as turpentine) to purified methanol that can be used in the CIO2 production process which follows. A partially-completed P&ID is attached for this purification process. Control System Design The methanol purification process contains several control systems designed to keep it running safely, while producing methanol of the desired purity. In this section, each incomplete control system associated with a transmitter (e.g. TT, LT) shown in the methanol purification plant P&ID is to be designed, as well as the control variables it is using to maintain control of the process. Indicate and label each loop on the P&ID provided. Add the control strategy (dashed line between sensor and instrument) on the P&ID as well. The following must also be listed/described for each control loop: Measured variable Manipulated variable Loop type (open, feedforward, or feedback) Gain type (positive or negative) Suggested control method or sub-type (PI, PID, etc.) . . 10 SOG SYSTEM WARM WATER RETURN . MEANAL CONDENSER MILL WATER SUPPLY Open METANOL CELLE GULMETHANOL CALELOR WARM WATER STEAM PROCUCI METHANOL CECANTE XD VILL WATER TO FOUL CONDENSATE TAMK HOUT NOTAL DECA ILALLINE FEOL RECANTER PRODUCT METHANOL COOLER RERUK FROM REFLUX CONDENS ROL DECIR LEGE DOL DER PU UNGALOWPUM 3-0 EOUL METINGE LEBANTENG BOX TUL METHANOL PREHLAH TO CLO2 SYSTEM EOL METHANOL BECANTER EL METAAL PRODUCT METHANOL TANK PRODUCE METHANOL ELANGOR RED OL TO FOUL CONDENSATE TAI SOTE 1. DUPVET SOHO PROPORED FOR SUPPLY WILL RED OIL PUMP AH. LUNDBERG SYSTEMS LIMITED AHL METHANOL, PURIFICATION SYSTEM FLOWSHEET ON PO

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts