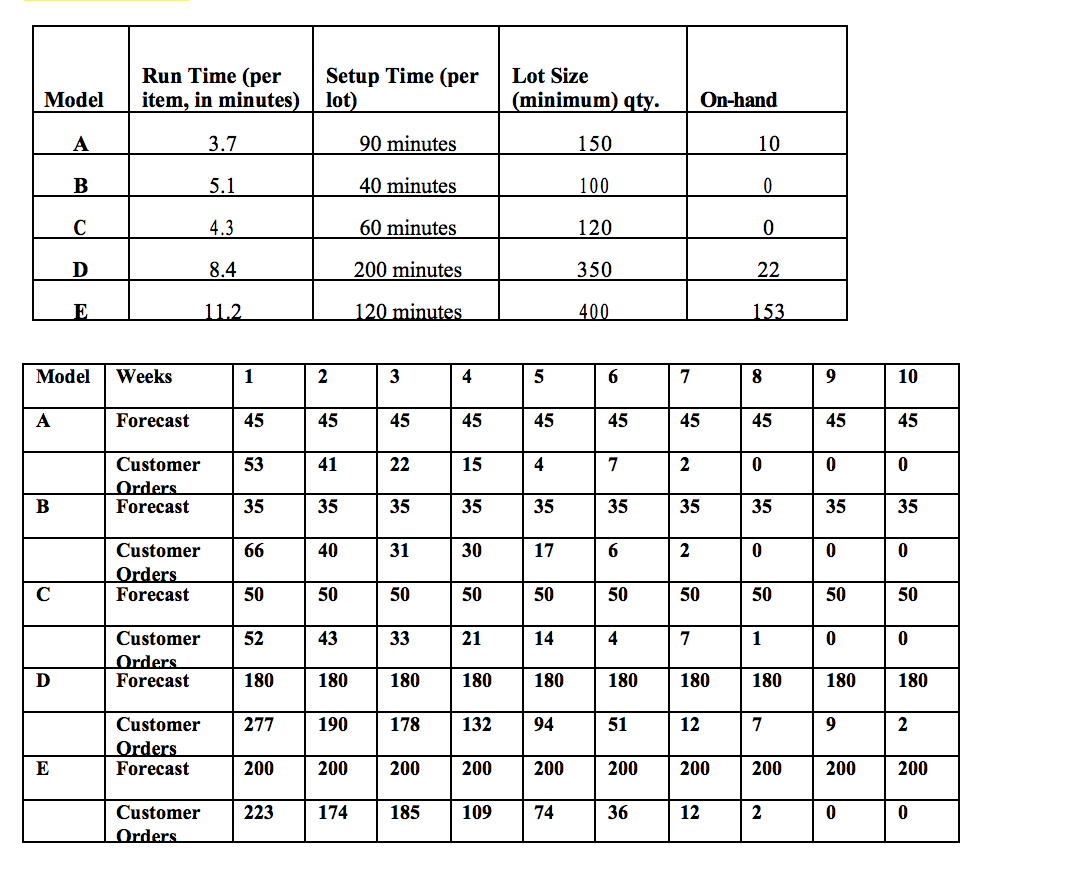

Question: Develop an MPS/ATP schedule based on the forecast and order data provided. Develop a rough-cut capacity plan based on the MPS schedule and the data

- Develop an MPS/ATP schedule based on the forecast and order data provided.

- Develop a rough-cut capacity plan based on the MPS schedule and the data provided.

- Discuss any issues that you notice based on the two plans that you have developed. Also, if you were to tweak your production schedule to work around some of the constraints, how would you do that?

Run Time (per item, in minutes) Setup Time (per lot) Lot Size (minimum) aty. Model On-hand A 3.7 90 minutes 150 10 B 5.1 40 minutes 100 0 4.3 60 minutes 120 0 D 8.4 200 minutes 350 22 . 11.2. 120 minutes 400 153 Model Weeks 1 2 3 4 5 6 7 8 9 10 A Forecast 45 45 45 45 45 45 45 45 45 45 53 41 22 15 4 7 2 0 0 0 Customer Orders Forecast B 35 35 35 35 35 35 35 35 35 35 66 40 31 30 17 6 2 0 0 0 Customer Orders Forecast C 50 50 50 50 50 50 50 50 50 50 52 43 33 21 14 4 7 1 0 0 Customer Orders Forecast D 180 180 180 180 180 180 180 180 180 180 277 190 178 132 94 51 12 9 2 Customer Orders Forecast E 200 200 200 200 200 200 200 200 200 200 223 174 185 109 74 36 12 2 0 0 Customer Orders Run Time (per item, in minutes) Setup Time (per lot) Lot Size (minimum) aty. Model On-hand A 3.7 90 minutes 150 10 B 5.1 40 minutes 100 0 4.3 60 minutes 120 0 D 8.4 200 minutes 350 22 . 11.2. 120 minutes 400 153 Model Weeks 1 2 3 4 5 6 7 8 9 10 A Forecast 45 45 45 45 45 45 45 45 45 45 53 41 22 15 4 7 2 0 0 0 Customer Orders Forecast B 35 35 35 35 35 35 35 35 35 35 66 40 31 30 17 6 2 0 0 0 Customer Orders Forecast C 50 50 50 50 50 50 50 50 50 50 52 43 33 21 14 4 7 1 0 0 Customer Orders Forecast D 180 180 180 180 180 180 180 180 180 180 277 190 178 132 94 51 12 9 2 Customer Orders Forecast E 200 200 200 200 200 200 200 200 200 200 223 174 185 109 74 36 12 2 0 0 Customer Orders

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts