Question: Develop Linear Program models to minimize costs for the followings: Extruders The extrusion process is capital intensive, as is the investment in the facilities required

Develop Linear Program models to minimize costs for the followings:

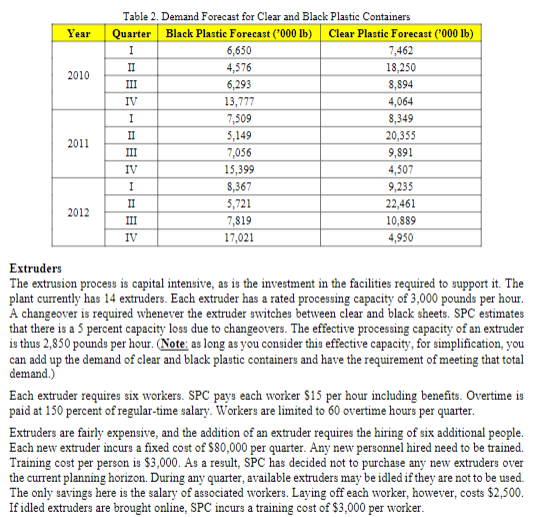

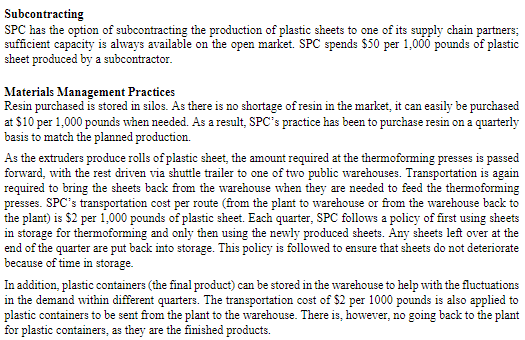

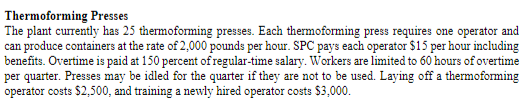

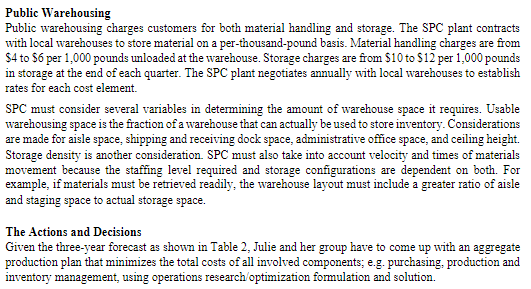

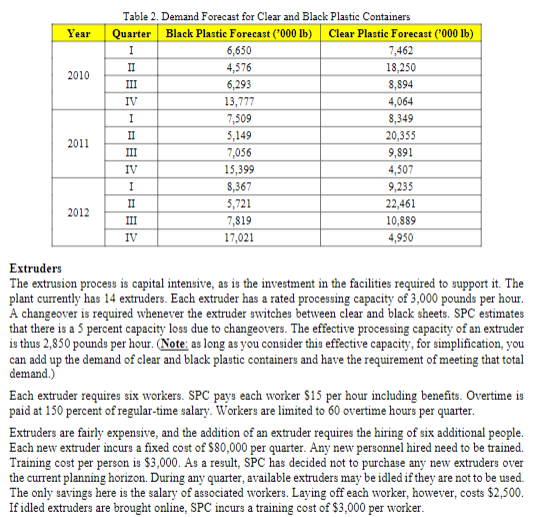

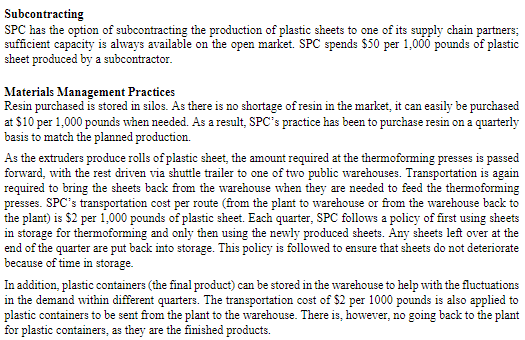

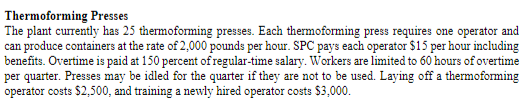

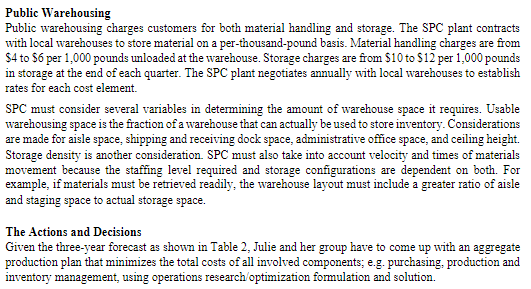

Extruders The extrusion process is capital intensive, as is the investment in the facilities required to support it. The plant currently has 14 extruders. Each extruder has a rated processing capacity of 3,000 pounds per hour. A changeover is required whenever the extruder switches between clear and black sheets. SPC estimates that there is a 5 percent capacity loss due to changeovers. The effective processing capacity of an extruder is thus 2,850 pounds per hour. (Note: as long as you consider this effective capacity, for simplification, you can add up the demand of clear and black plastic containers and have the requirement of meeting that total demand.) Each extruder requires six workers. SPC pays each worker $15 per hour including benefits. Overtime is paid at 150 percent of regular-time salary. Workers are limited to 60 overtime hours per quarter. Extruders are fairly expensive, and the addition of an extruder requires the hiring of six additional people. Each new extruder incurs a fixed cost of $80,000 per quarter. Any new personnel hired need to be trained. Training cost per person is $3,000. As a result, $PC has decided not to purchase any new extruders over the current planning horizon. During any quarter, available extruders may be idled if they are not to be used. The only savings here is the salary of associated workers. Laying off each worker, however, costs $2,500. If idled extruders are brought online, SPC incurs a training cost of $3,000 per worker. Subcontracting SPC has the option of subcontracting the production of plastic sheets to one of its supply chain partners; sufficient capacity is always available on the open market. SPC spends $50 per 1,000 pounds of plastic sheet produced by a subcontractor. Materials Management Practices Resin purchased is stored in silos. As there is no shortage of resin in the market, it can easily be purchased at $10 per 1,000 pounds when needed. As a result, SPC's practice has been to purchase resin on a quarterly basis to match the planned production. As the extruders produce rolls of plastic sheet, the amount required at the thermoforming presses is passed forward, with the rest driven via shuttle trailer to one of two public warehouses. Transportation is again required to bring the sheets back from the warehouse when they are needed to feed the thermoforming presses. SPC's transportation cost per route (from the plant to warehouse or from the warehouse back to the plant) is $2 per 1,000 pounds of plastic sheet. Each quarter, SPC follows a policy of first using sheets in storage for thermoforming and only then using the newly produced sheets. Any sheets left over at the end of the quarter are put back into storage. This policy is followed to ensure that sheets do not deteriorate because of time in storage. In addition, plastic containers (the final product) can be stored in the warehouse to help with the fluctuations in the demand within different quarters. The transportation cost of $2 per 1000 pounds is also applied to plastic containers to be sent from the plant to the warehouse. There is, however, no going back to the plant for plastic containers, as they are the finished products. Thermoforming Presses The plant currently has 25 thermoforming presses. Each thermoforming press requires one operator and can produce containers at the rate of 2,000 pounds per hour. SPC pays each operator $15 per hour including benefits. Overtime is paid at 150 percent of regular-time salary. Workers are limited to 60 hours of overtime per quarter. Presses may be idled for the quarter if they are not to be used. Laying off a thermoforming operator costs $2,500, and training a newly hired operator costs $3,000. Public Warehousing Public warehousing charges customers for both material handling and storage. The SPC plant contracts with local warehouses to store material on a per-thousand-pound basis. Material handling charges are from $4 to $6 per 1,000 pounds unloaded at the warehouse. Storage charges are from $10 to $12 per 1,000 pounds in storage at the end of each quarter. The SPC plant negotiates annually with local warehouses to establish rates for each cost element. SPC must consider several variables in determining the amount of warehouse space it requires. Usable warehousing space is the fraction of a warehouse that can actually be used to store inventory. Considerations are made for aisle space, shipping and receiving dock space, administrative office space, and ceiling height. Storage density is another consideration. SPC must also take into account velocity and times of materials movement because the staffing level required and storage configurations are dependent on both. For example, if materials must be retrieved readily, the warehouse layout must include a greater ratio of aisle and staging space to actual storage space. The Actions and Decisions Given the three-year forecast as shown in Table 2, Julie and her group have to come up with an aggregate production plan that minimizes the total costs of all involved components; e.g. purchasing, production and inventory management, using operations research/optimization formulation and solution