Question: Do organizations know how to evaluate their suppliers? Do they use the right data? Is there a consistent approach by different departments within an organization?

Do organizations know how to evaluate their suppliers? Do they use the right data? Is there a consistent approach by different departments within an organization? The case study on pp shows that evaluating suppliers is itself a risk. TABLE

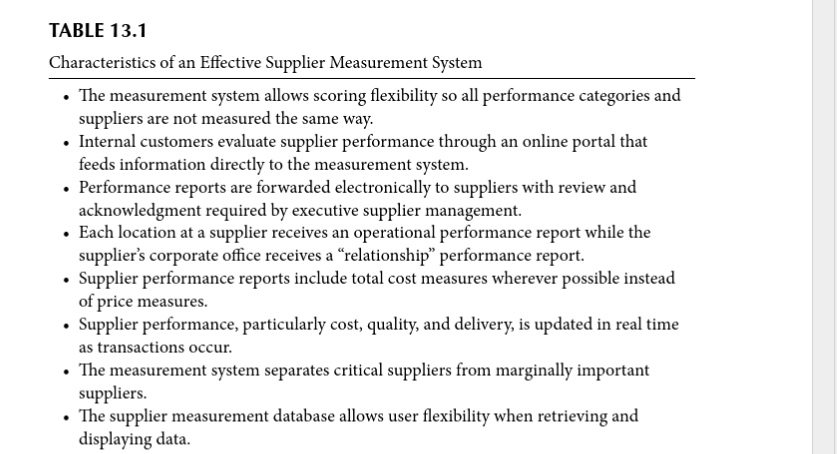

Characteristics of an Effective Supplier Measurement System

The measurement system allows scoring flexibility so all performance categories and

suppliers are not measured the same way.

Internal customers evaluate supplier performance through an online portal that

feeds information directly to the measurement system.

Performance reports are forwarded electronically to suppliers with review and

acknowledgment required by executive supplier management.

Each location at a supplier receives an operational performance report while the

supplier's corporate office receives a "relationship" performance report.

Supplier performance reports include total cost measures wherever possible instead

of price measures.

Supplier performance, particularly cost, quality, and delivery, is updated in real time

as transactions occur.

The measurement system separates critical suppliers from marginally important

suppliers.

The supplier measurement database allows user flexibility when retrieving and

displaying data.Table shows characteristics of an effective supply measurement system. Choose up to three of these characteristics that you would prioritize as the most important and provide reasons why. Use of real life examples is helpful, if you can obtain them.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock