Question: Electronics Assembly Inc. is a contract manufacturer that assembles consumer electronics for a number of companies. Currently, the operations manager is assessing the capacity requirements

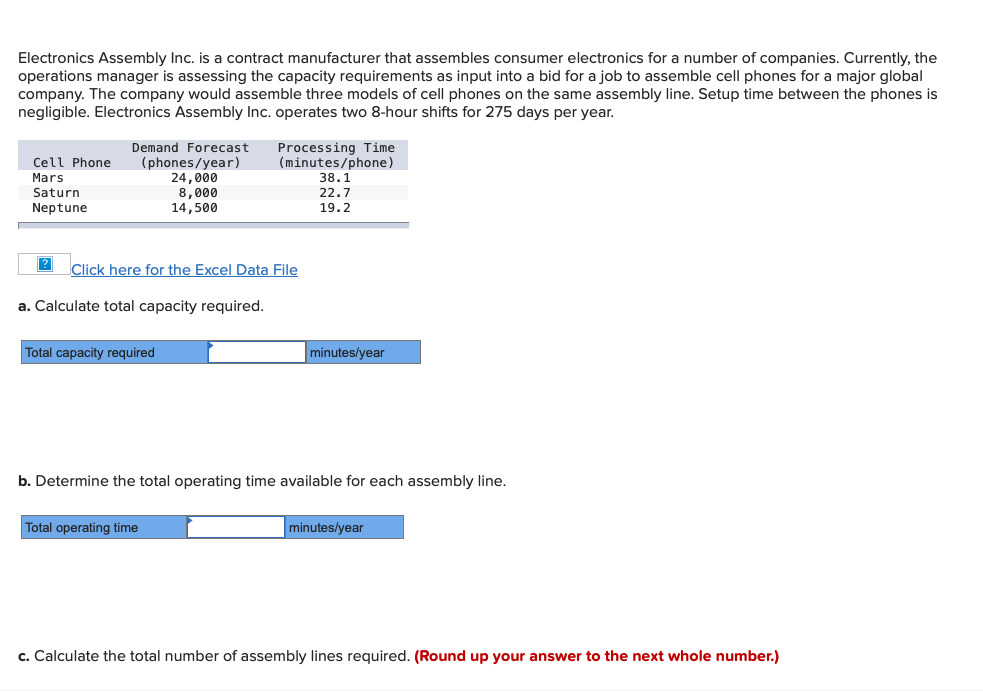

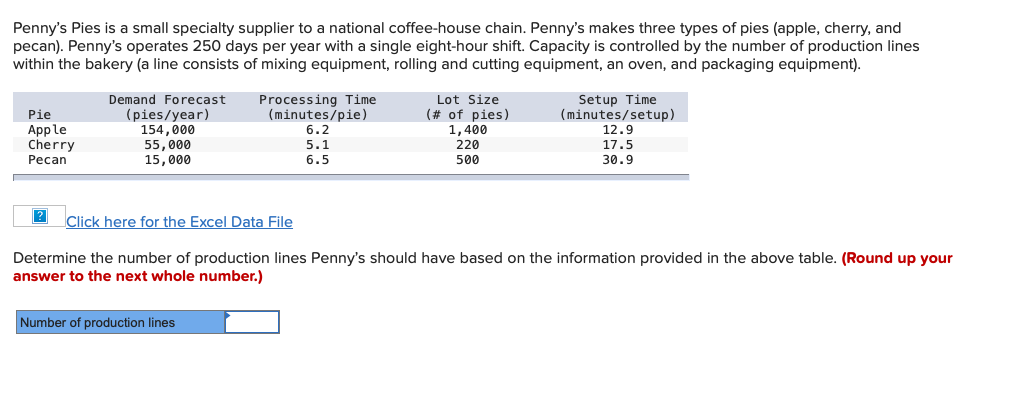

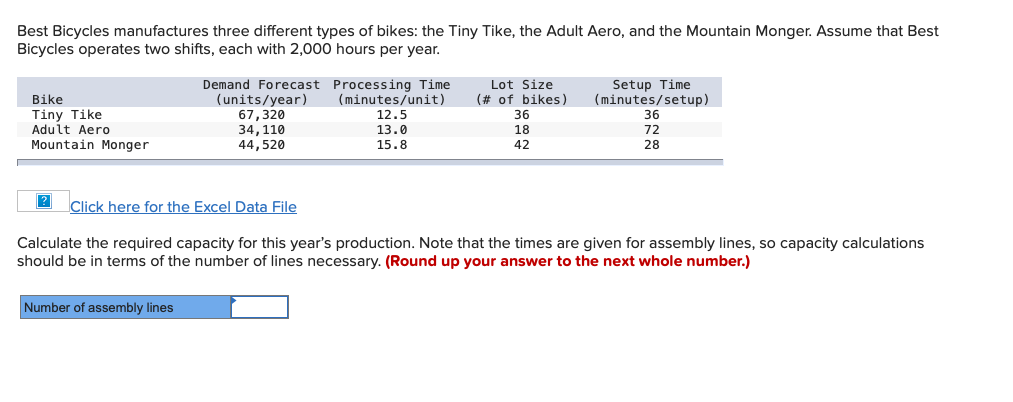

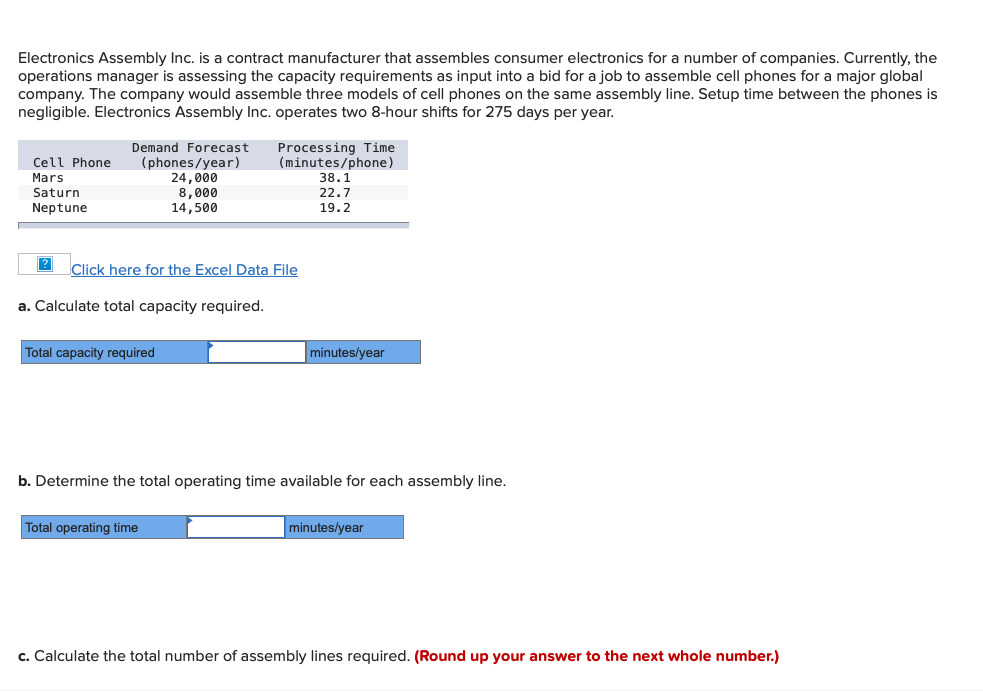

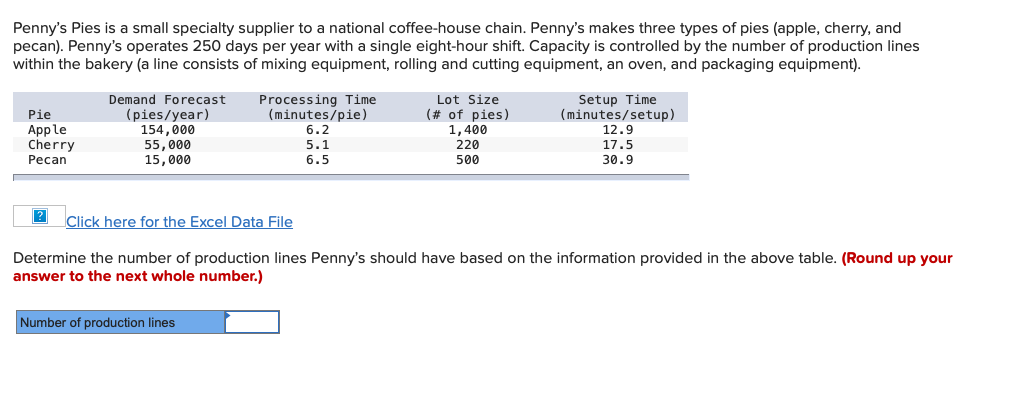

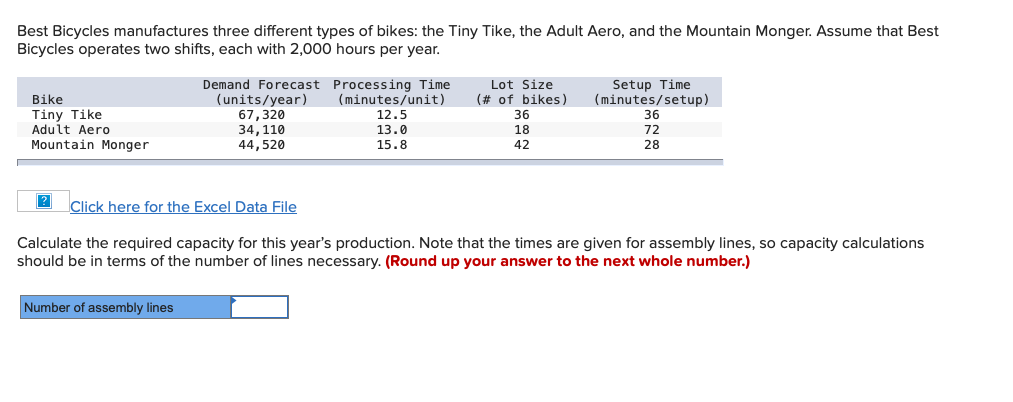

Electronics Assembly Inc. is a contract manufacturer that assembles consumer electronics for a number of companies. Currently, the operations manager is assessing the capacity requirements as input into a bid for a job to assemble cell phones for a major global company. The company would assemble three models of cell phones on the same assembly line. Setup time between the phones is negligible. Electronics Assembly Inc. operates two 8-hour shifts for 275 days per year. Cell Phone Mars Saturn Neptune Demand Forecast (phones/year) 24,000 8,000 14,500 Processing Time (minutes/phone) 38.1 22.7 19.2 ? Click here for the Excel Data File a. Calculate total capacity required. Total capacity required minutes/year b. Determine the total operating time available for each assembly line. Total operating time minutes/year c. Calculate the total number of assembly lines required. (Round up your answer to the next whole number.) Penny's Pies is a small specialty supplier to a national coffee-house chain. Penny's makes three types of pies (apple, cherry, and pecan). Penny's operates 250 days per year with a single eight-hour shift. Capacity is controlled by the number of production lines within the bakery (a line consists of mixing equipment, rolling and cutting equipment, an oven, and packaging equipment). Pie Apple Cherry Pecan Demand Forecast (pies/year) 154,000 55,000 15,000 Processing Time (minutes/pie) 6.2 5.1 6.5 Lot Size (# of pies) 1,400 220 500 Setup Time (minutes/setup) 12.9 17.5 30.9 Click here for the Excel Data File Determine the number of production lines Penny's should have based on the information provided in the above table. (Round up your answer to the next whole number.) Number of production lines Best Bicycles manufactures three different types of bikes: the Tiny Tike, the Adult Aero, and the Mountain Monger. Assume that Best Bicycles operates two shifts, each with 2,000 hours per year. Bike Tiny Tike Adult Aero Mountain Monger Demand Forecast Processing Time (units/year) (minutes/unit) 67,320 12.5 34,110 44,520 15.8 Lot Size (# of bikes) 36 18 42 Setup Time (minutes/setup) 36 72 28 13.0 Click here for the Excel Data File Calculate the required capacity for this year's production. Note that the times are given for assembly lines, so capacity calculations should be in terms of the number of lines necessary. (Round up your answer to the next whole number.) Number of assembly lines