Question: Exercise 2 is a quality cost analysis assignment. It consists of two parts, each worth 5 points. Important Note: You must complete Exercise 2A with

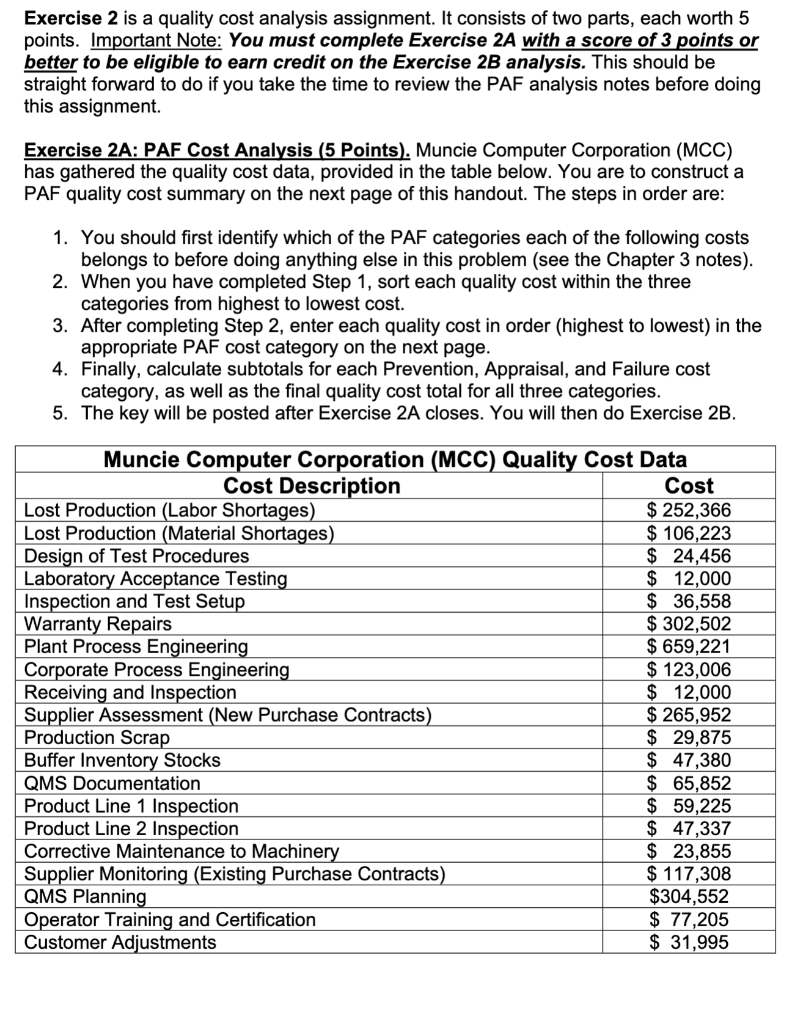

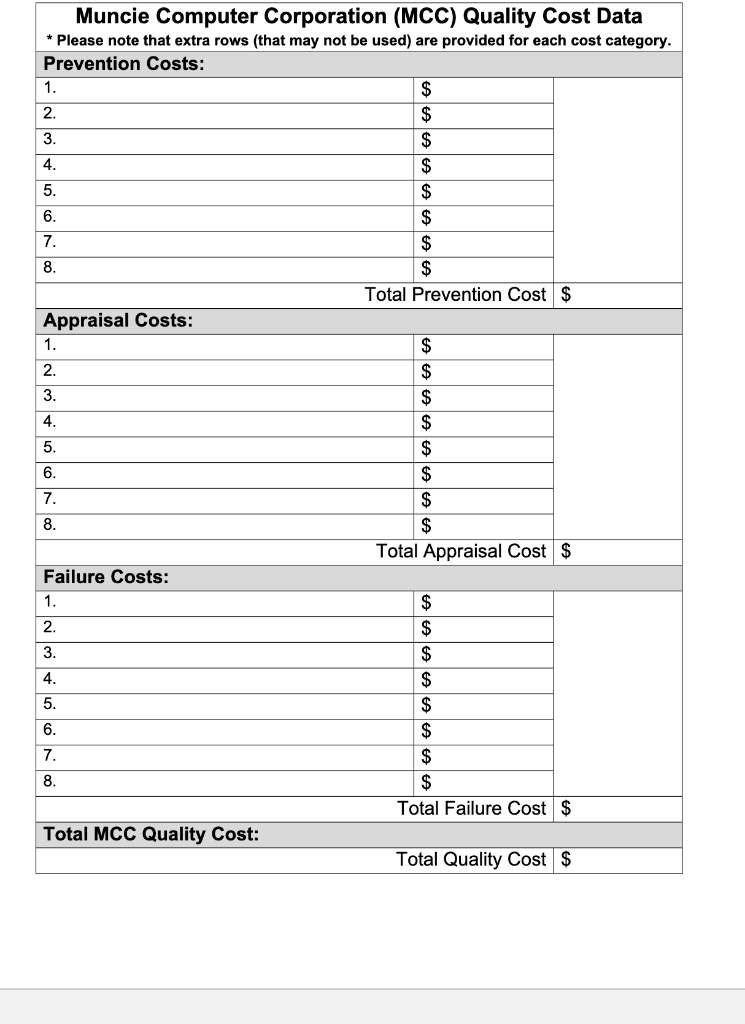

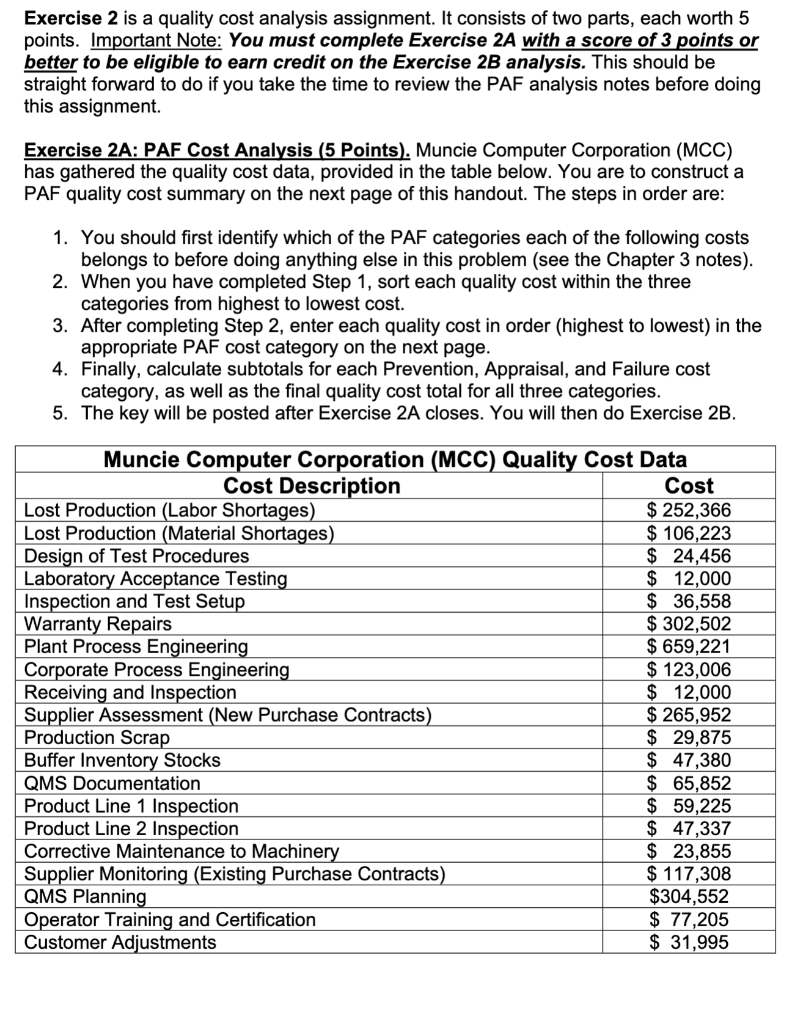

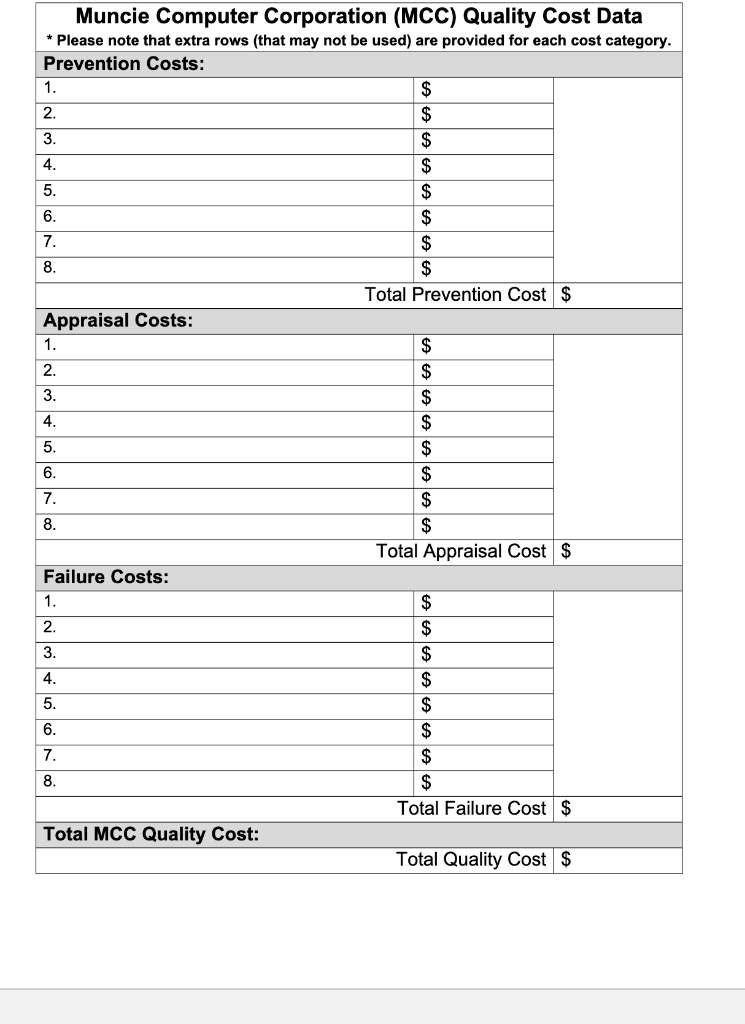

Exercise 2 is a quality cost analysis assignment. It consists of two parts, each worth 5 points. Important Note: You must complete Exercise 2A with a score of 3 points or better to be eligible to earn credit on the Exercise 2B analysis. This should be straight forward to do if you take the time to review the PAF analysis notes before doing this assignment. Exercise 2A: PAF Cost Analysis (5 Points). Muncie Computer Corporation (MCC) has gathered the quality cost data, provided in the table below. You are to construct a PAF quality cost summary on the next page of this handout. The steps in order are: 1. You should first identify which of the PAF categories each of the following costs belongs to before doing anything else in this problem (see the Chapter 3 notes). 2. When you have completed Step 1, sort each quality cost within the three categories from highest to lowest cost. 3. After completing Step 2, enter each quality cost in order (highest to lowest) in the appropriate PAF cost category on the next page. 4. Finally, calculate subtotals for each Prevention, Appraisal, and Failure cost category, as well as the final quality cost total for all three categories. 5. The key will be posted after Exercise 2A closes. You will then do Exercise 2B. Muncie Computer Corporation (MCC) Quality Cost Data Cost Description Cost Lost Production (Labor Shortages) $ 252,366 Lost Production (Material Shortages) $ 106,223 Design of Test Procedures $ 24,456 Laboratory Acceptance Testing $ 12,000 Inspection and Test Setup $ 36,558 Warranty Repairs $ 302,502 Plant Process Engineering $ 659,221 Corporate Process Engineering $ 123,006 Receiving and Inspection $ 12,000 Supplier Assessment (New Purchase Contracts) $ 265,952 Production Scrap $ 29,875 Buffer Inventory Stocks $ 47,380 QMS Documentation $ 65,852 Product Line 1 Inspection $ 59,225 Product Line 2 Inspection $ 47,337 Corrective Maintenance to Machinery $ 23,855 Supplier nitoring (Existing Purchase Contracts) $ 117,308 QMS Planning $304,552 Operator Training and Certification $ 77,205 Customer Adjustments $ 31,995 4. $ Muncie Computer Corporation (MCC) Quality Cost Data * Please note that extra rows (that may not be used) are provided for each cost category. Prevention Costs: 1. $ 2. $ 3. $ $ 5. $ 6. 7. $ 8. $ Total Prevention Cost $ Appraisal Costs: 1. $ 2. $ 3. $ 4. $ 5. $ 6. $ 7. $ 8. $ Total Appraisal Cost $ Failure Costs: 1. $ 2. $ 3. $ 4. $ 5. $ 6. $ 7. $ $ Total Failure Cost $ Total MCC Quality Cost: Total Quality Cost $