Question: Exercise 2 is a quality cost analysis assignment. It consists of two parts, each worth 5 points. Important Note: You must have completed Exercise 2A

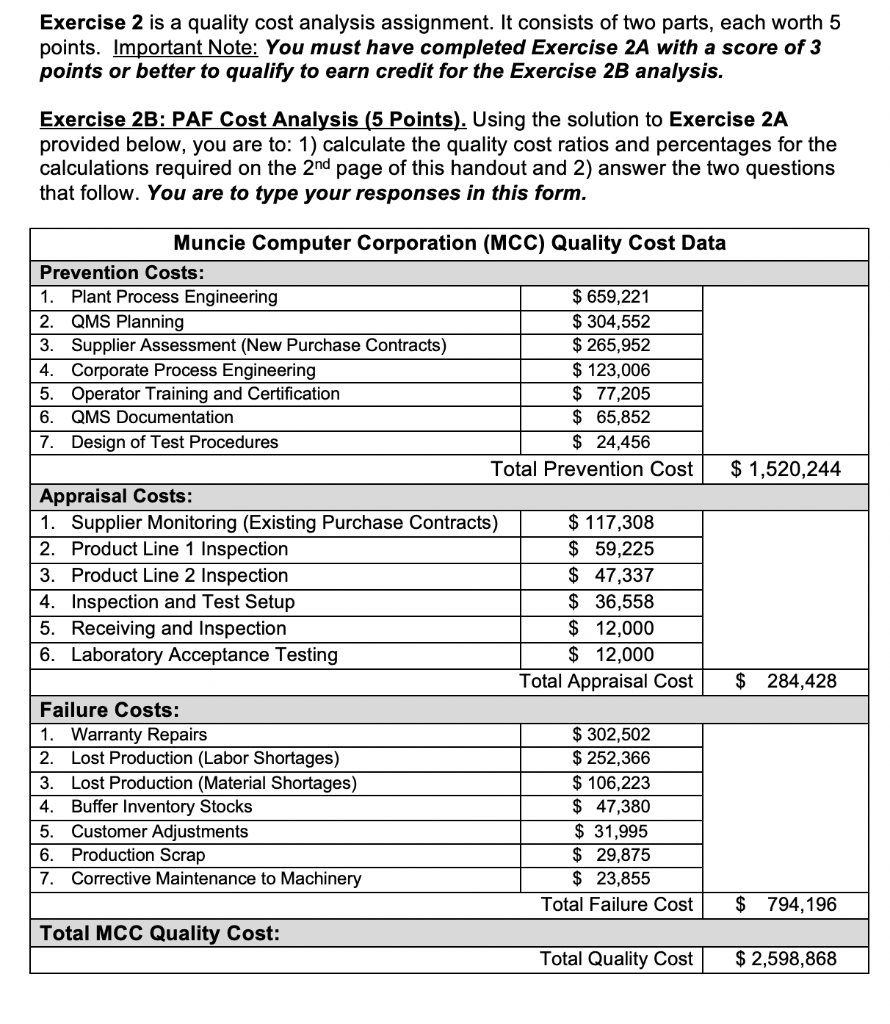

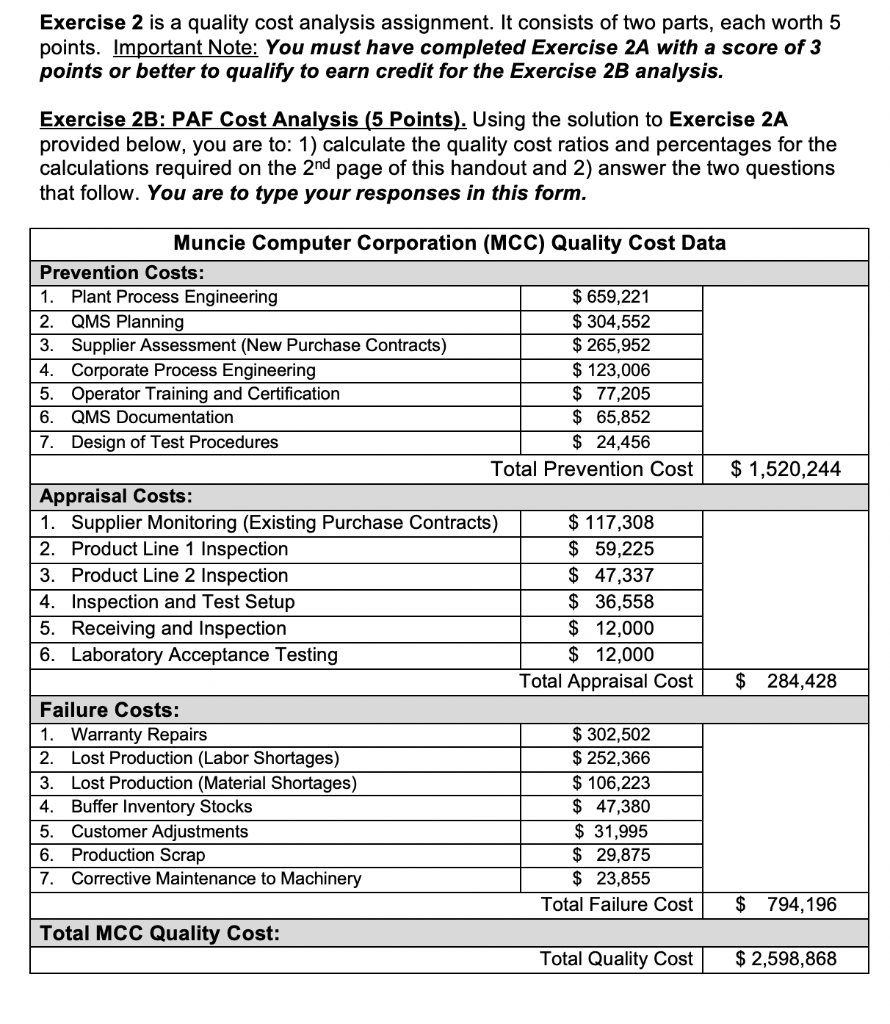

Exercise 2 is a quality cost analysis assignment. It consists of two parts, each worth 5 points. Important Note: You must have completed Exercise 2A with a score of 3 points or better to qualify to earn credit for the Exercise 2B analysis. Exercise 2B: PAF Cost Analysis (5 Points). Using the solution to Exercise 2A provided below, you are to: 1) calculate the quality cost ratios and percentages for the calculations required on the 2nd page of this handout and 2) answer the two questions that follow. You are to type your responses in this form. Muncie Computer Corporation (MCC) Quality Cost Data Prevention Costs: 1. Plant Process Engineering $ 659,221 2. QMS Planning $ 304,552 3. Supplier Assessment (New Purchase Contracts) $ 265,952 4. Corporate Process Engineering $ 123,006 5. Operator Training and Certification $ 77,205 6. QMS Documentation $ 65,852 7. Design of Test Procedures $ 24,456 Total Prevention Cost $ 1,520,244 Appraisal Costs: 1. Supplier Monitoring (Existing Purchase Contracts) $ 117,308 2. Product Line 1 Inspection $ 59,225 3. Product Line 2 Inspection $ 47,337 4. Inspection and Test Setup $ 36,558 5. Receiving and Inspection $ 12,000 6. Laboratory Acceptance Testing $ 12,000 Total Appraisal Cost $ 284,428 Failure Costs: 1. Warranty Repairs $ 302,502 2. Lost Production (Labor Shortages) $ 252,366 3. Lost Production (Material Shortages) $ 106,223 4. Buffer Inventory Stocks $ 47,380 5. Customer Adjustments $ 31,995 6. Production Scrap $ 29,875 7. Corrective Maintenance to Machinery $ 23,855 Total Failure Cost $ 794,196 Total MCC Quality Cost: Total Quality Cost $ 2,598,868 Exercise 2 is a quality cost analysis assignment. It consists of two parts, each worth 5 points. Important Note: You must have completed Exercise 2A with a score of 3 points or better to qualify to earn credit for the Exercise 2B analysis. Exercise 2B: PAF Cost Analysis (5 Points). Using the solution to Exercise 2A provided below, you are to: 1) calculate the quality cost ratios and percentages for the calculations required on the 2nd page of this handout and 2) answer the two questions that follow. You are to type your responses in this form. Muncie Computer Corporation (MCC) Quality Cost Data Prevention Costs: 1. Plant Process Engineering $ 659,221 2. QMS Planning $ 304,552 3. Supplier Assessment (New Purchase Contracts) $ 265,952 4. Corporate Process Engineering $ 123,006 5. Operator Training and Certification $ 77,205 6. QMS Documentation $ 65,852 7. Design of Test Procedures $ 24,456 Total Prevention Cost $ 1,520,244 Appraisal Costs: 1. Supplier Monitoring (Existing Purchase Contracts) $ 117,308 2. Product Line 1 Inspection $ 59,225 3. Product Line 2 Inspection $ 47,337 4. Inspection and Test Setup $ 36,558 5. Receiving and Inspection $ 12,000 6. Laboratory Acceptance Testing $ 12,000 Total Appraisal Cost $ 284,428 Failure Costs: 1. Warranty Repairs $ 302,502 2. Lost Production (Labor Shortages) $ 252,366 3. Lost Production (Material Shortages) $ 106,223 4. Buffer Inventory Stocks $ 47,380 5. Customer Adjustments $ 31,995 6. Production Scrap $ 29,875 7. Corrective Maintenance to Machinery $ 23,855 Total Failure Cost $ 794,196 Total MCC Quality Cost: Total Quality Cost $ 2,598,868