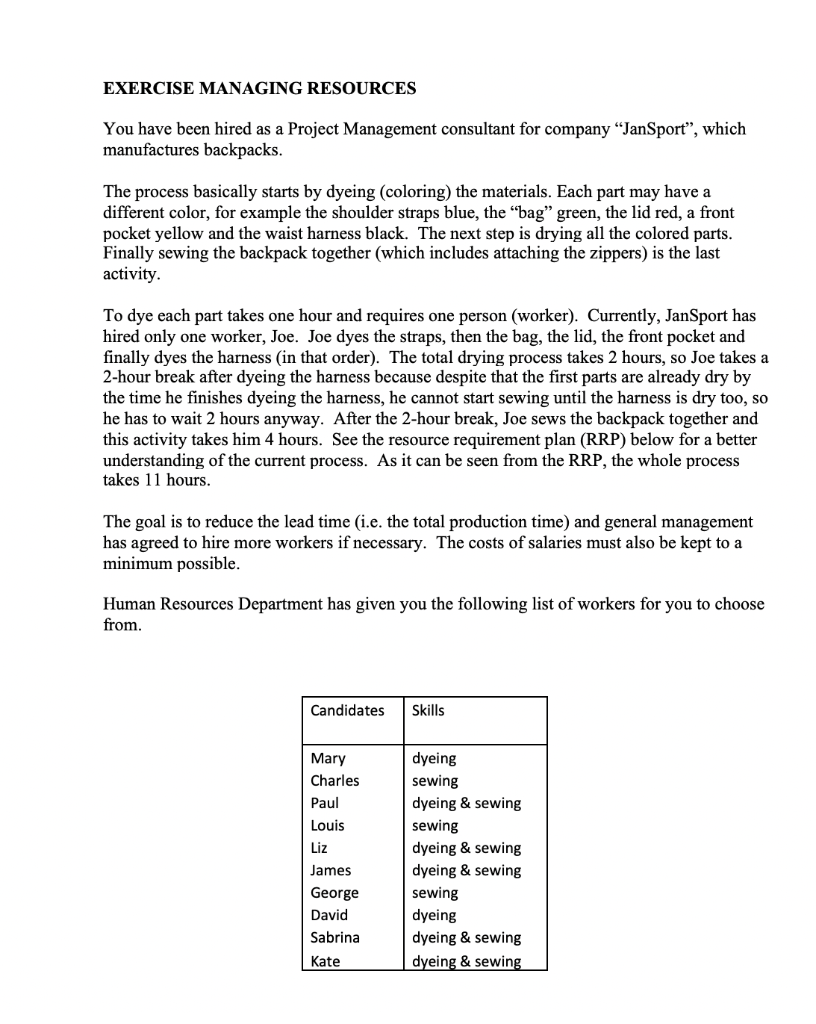

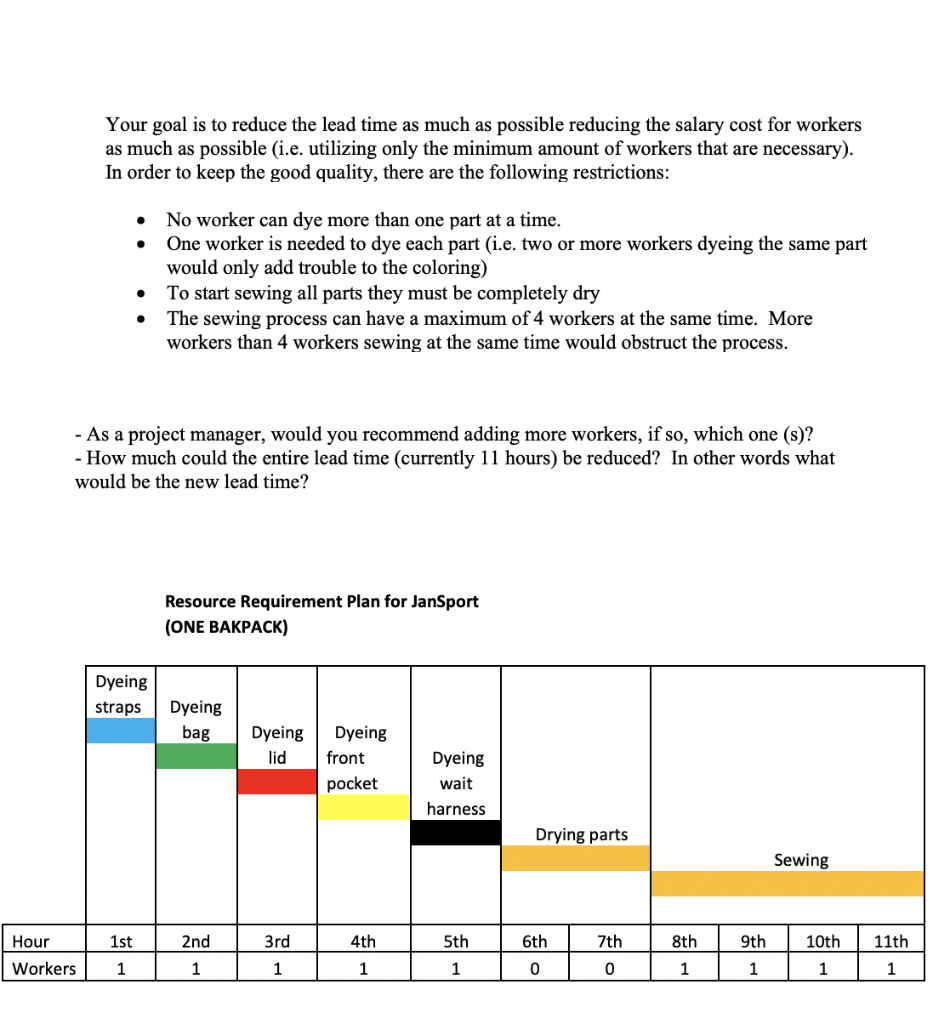

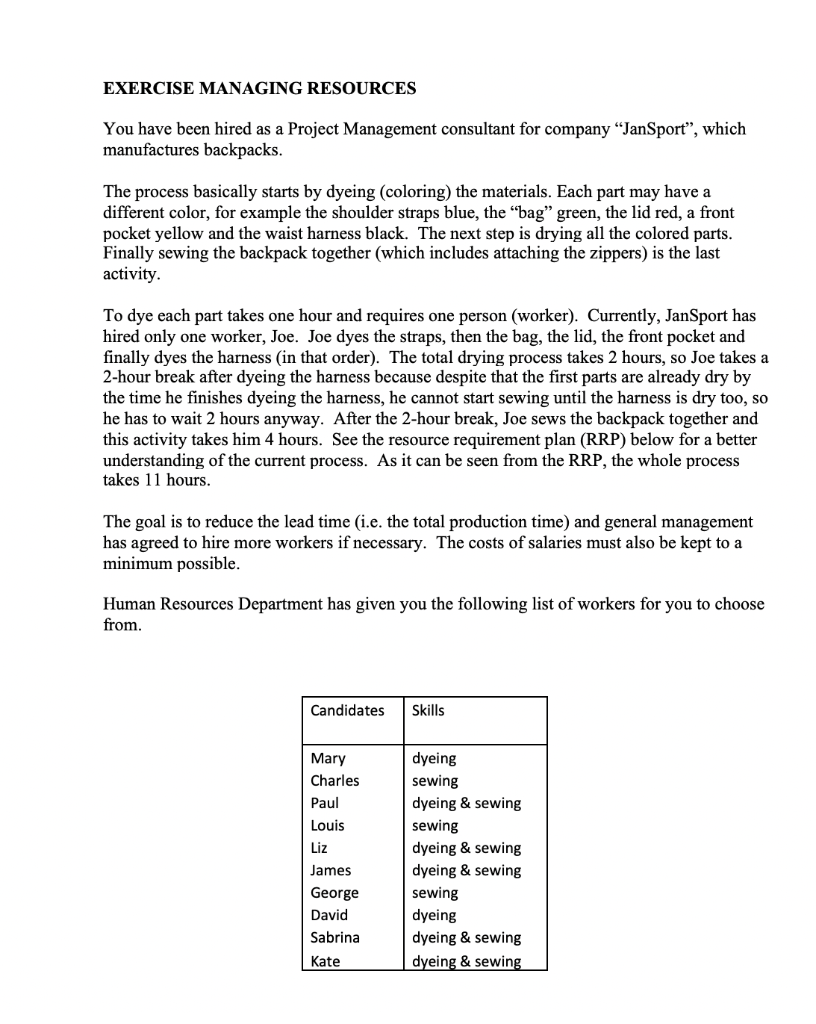

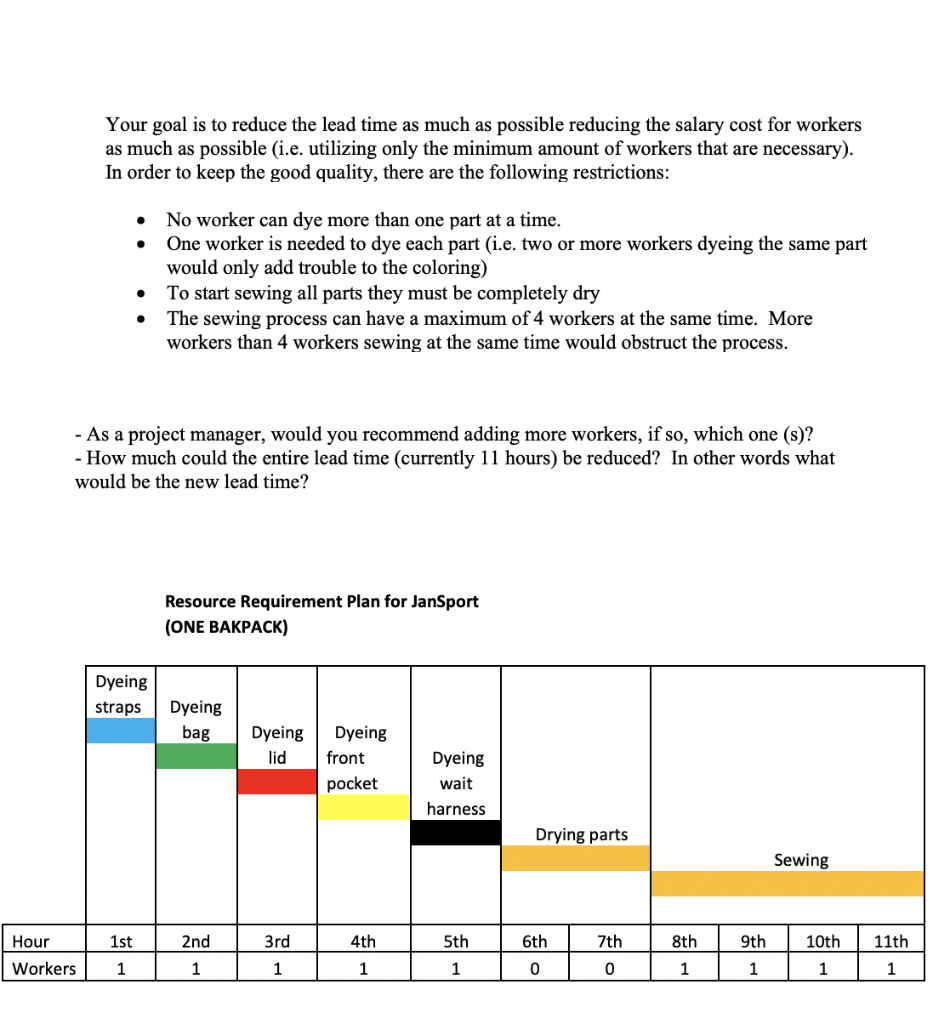

EXERCISE MANAGING RESOURCES You have been hired as a Project Management consultant for company JanSport", which manufactures backpacks. The process basically starts by dyeing (coloring) the materials. Each part may have a different color, for example the shoulder straps blue, the bag green, the lid red, a front pocket yellow and the waist harness black. The next step is drying all the colored parts. Finally sewing the backpack together (which includes attaching the zippers) is the last activity. To dye each part takes one hour and requires one person (worker). Currently, JanSport has hired only one worker, Joe. Joe dyes the straps, then the bag, the lid, the front pocket and finally dyes the harness (in that order). The total drying process takes 2 hours, so Joe takes a 2-hour break after dyeing the harness because despite that the first parts are already dry by the time he finishes dyeing the harness, he cannot start sewing until the harness is dry too, so he has to wait 2 hours anyway. After the 2-hour break, Joe sews the backpack together and this activity takes him 4 hours. See the resource requirement plan (RRP) below for a better understanding of the current process. As it can be seen from the RRP, the whole process takes 11 hours. The goal is to reduce the lead time (i.e. the total production time) and general management has agreed to hire more workers if necessary. The costs of salaries must also be kept to a minimum possible. Human Resources Department has given you the following list of workers for you to choose from. Candidates Skills Mary Charles Paul Louis Liz James George David Sabrina Kate dyeing sewing dyeing & sewing sewing dyeing & sewing dyeing & sewing sewing dyeing dyeing & sewing dyeing & sewing Your goal is to reduce the lead time as much as possible reducing the salary cost for workers as much as possible (i.e. utilizing only the minimum amount of workers that are necessary). In order to keep the good quality, there are the following restrictions: No worker can dye more than one part at a time. One worker is needed to dye each part (i.e. two or more workers dyeing the same part would only add trouble to the coloring) To start sewing all parts they must be completely dry The sewing process can have a maximum of 4 workers at the same time. More workers than 4 workers sewing at the same time would obstruct the process. - - As a project manager, would you recommend adding more workers, if so, which one (s)? - How much could the entire lead time (currently 11 hours) be reduced? In other words what would be the new lead time? Resource Requirement Plan for JanSport (ONE BAKPACK) Dyeing straps Dyeing bag Dyeing lid Dyeing front pocket Dyeing wait harness Drying parts Sewing Hour 1st 2nd 3rd 4th 5th 6th 7th 8th 9th 10th 11th Workers 1 1 1 1 1 0 0 1 1 1 1 EXERCISE MANAGING RESOURCES You have been hired as a Project Management consultant for company JanSport", which manufactures backpacks. The process basically starts by dyeing (coloring) the materials. Each part may have a different color, for example the shoulder straps blue, the bag green, the lid red, a front pocket yellow and the waist harness black. The next step is drying all the colored parts. Finally sewing the backpack together (which includes attaching the zippers) is the last activity. To dye each part takes one hour and requires one person (worker). Currently, JanSport has hired only one worker, Joe. Joe dyes the straps, then the bag, the lid, the front pocket and finally dyes the harness (in that order). The total drying process takes 2 hours, so Joe takes a 2-hour break after dyeing the harness because despite that the first parts are already dry by the time he finishes dyeing the harness, he cannot start sewing until the harness is dry too, so he has to wait 2 hours anyway. After the 2-hour break, Joe sews the backpack together and this activity takes him 4 hours. See the resource requirement plan (RRP) below for a better understanding of the current process. As it can be seen from the RRP, the whole process takes 11 hours. The goal is to reduce the lead time (i.e. the total production time) and general management has agreed to hire more workers if necessary. The costs of salaries must also be kept to a minimum possible. Human Resources Department has given you the following list of workers for you to choose from. Candidates Skills Mary Charles Paul Louis Liz James George David Sabrina Kate dyeing sewing dyeing & sewing sewing dyeing & sewing dyeing & sewing sewing dyeing dyeing & sewing dyeing & sewing Your goal is to reduce the lead time as much as possible reducing the salary cost for workers as much as possible (i.e. utilizing only the minimum amount of workers that are necessary). In order to keep the good quality, there are the following restrictions: No worker can dye more than one part at a time. One worker is needed to dye each part (i.e. two or more workers dyeing the same part would only add trouble to the coloring) To start sewing all parts they must be completely dry The sewing process can have a maximum of 4 workers at the same time. More workers than 4 workers sewing at the same time would obstruct the process. - - As a project manager, would you recommend adding more workers, if so, which one (s)? - How much could the entire lead time (currently 11 hours) be reduced? In other words what would be the new lead time? Resource Requirement Plan for JanSport (ONE BAKPACK) Dyeing straps Dyeing bag Dyeing lid Dyeing front pocket Dyeing wait harness Drying parts Sewing Hour 1st 2nd 3rd 4th 5th 6th 7th 8th 9th 10th 11th Workers 1 1 1 1 1 0 0 1 1 1 1