Question: facility planning Part A is produced on Machine 1 and then Machine 2 . One unit of Part A is assembled with two units of

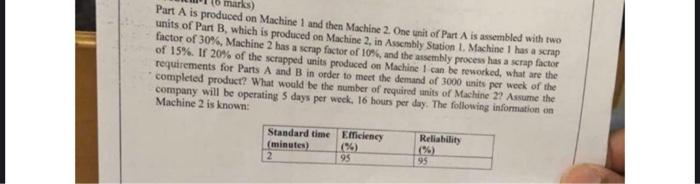

Part A is produced on Machine 1 and then Machine 2 . One unit of Part A is assembled with two units of Part B, which is produced on Machine 2 , in Assembly Station 1. Machine I has a serap factor of 30%, Machine 2 has a serap factor of 10%, and the asembly process has a serap factor of 15\%. If 20% of the scrapped units produced on Machine 1 can be reworked, what are the requirements for Parts A and B in order to meet the demand of 3000 units per week of the completed product? What would be the number of required anits of Machine 2? Asurne the company will be operating 5 days per week, 16 hours per day. The following information on Machine 2 is known

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts