Question: Part A is produced on machine 1 and then machine 2. One unit of Part A is assembled with three units of Part B,

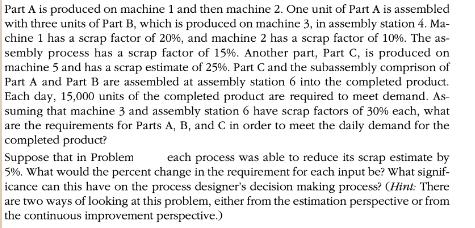

Part A is produced on machine 1 and then machine 2. One unit of Part A is assembled with three units of Part B, which is produced on machine 3, in assembly station 4. Ma- chine 1 has a scrap factor of 20%, and machine 2 has a scrap factor of 10%. The as- sembly process has a scrap factor of 15%. Another part, Part C, is produced on machine 5 and has a scrap estimate of 25%. Part C and the subassembly comprison of Part A and Part B are assembled at assembly station 6 into the completed product. Each day, 15,000 units of the completed product are required to meet demand. As- suming that machine 3 and assembly station 6 have scrap factors of 30% each, what are the requirements for Parts A, B, and C in order to meet the daily demand for the completed product? Suppose that in Problem each process was able to reduce its scrap estimate by 5%. What would the percent change in the requirement for each input be? What signif- icance can this have on the process designer's decision making process? (Hint: There are two ways of looking at this problem, either from the estimation perspective or from the continuous improvement perspective.)

Step by Step Solution

3.50 Rating (160 Votes )

There are 3 Steps involved in it

The detailed answer for the above question is provided below Here to calculate the requirement for P... View full answer

Get step-by-step solutions from verified subject matter experts