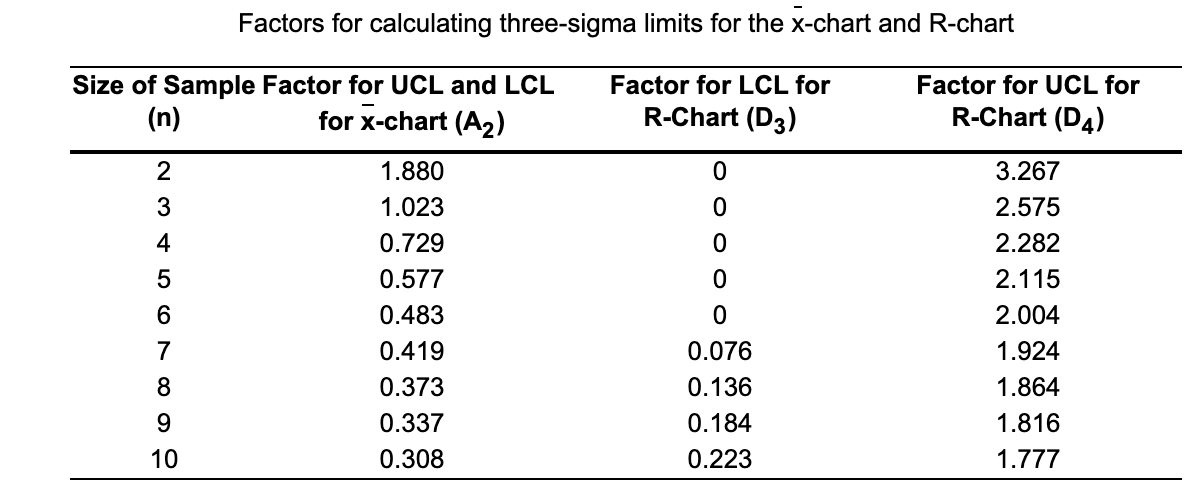

Question: Factors for calculating three-sigma limits for the X-chart and R-chart Size of Sample Factor for UCL and LCL (n) for X-chart (A2) Factor for LCL

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

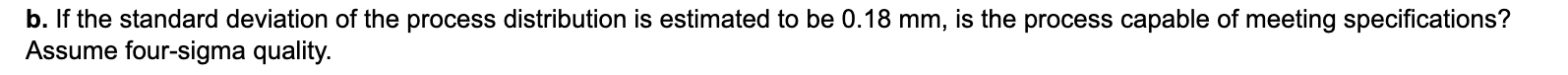

Step: 2 Unlock

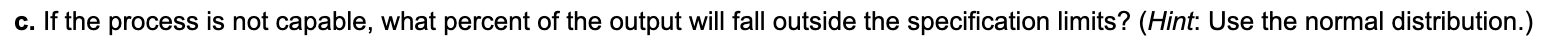

Step: 3 Unlock