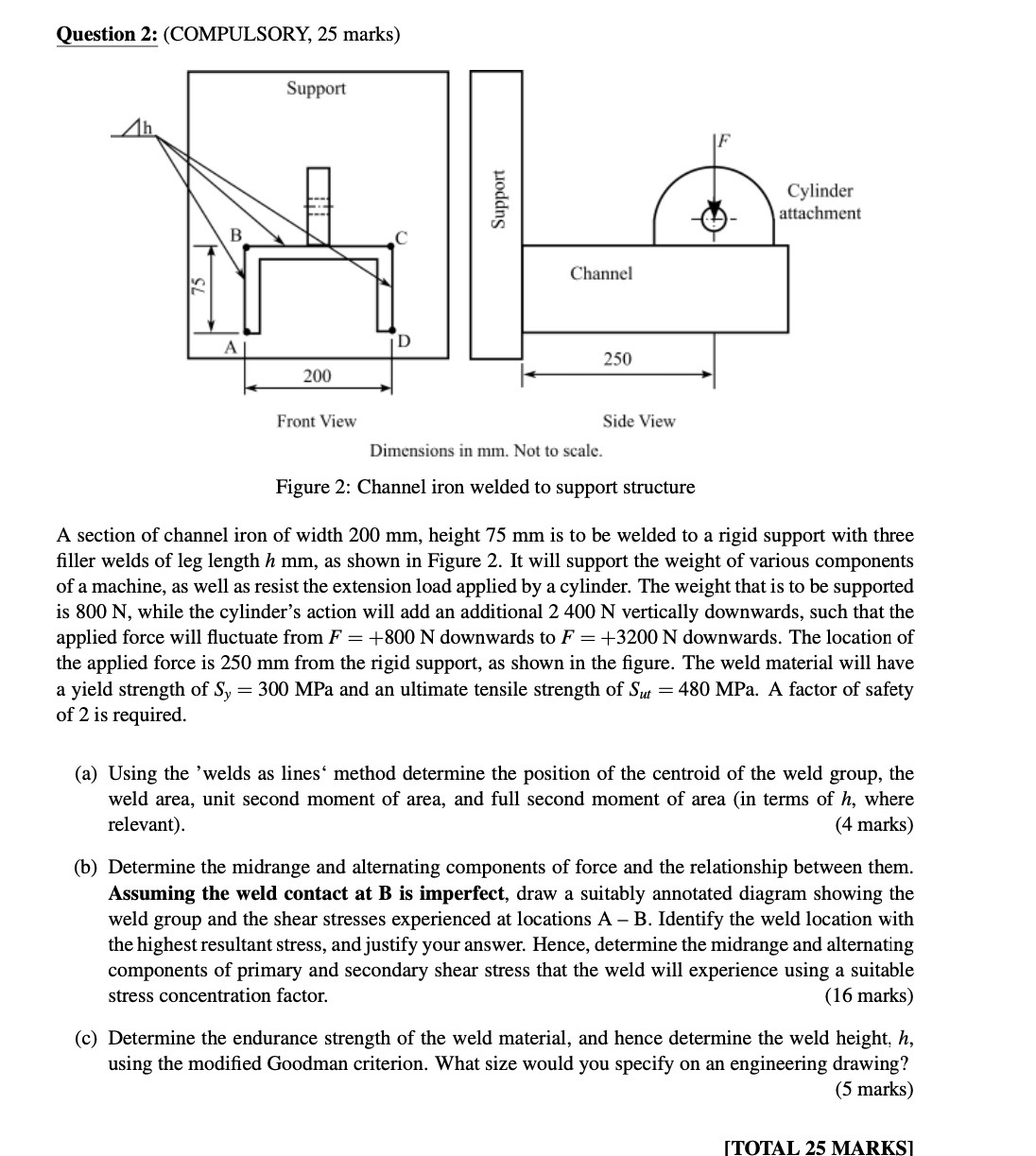

Question: Figure 2 : Channel iron welded to support structure A section of channel iron of width 2 0 0 mm , height 7 5 mm

Figure : Channel iron welded to support structure

A section of channel iron of width mm height mm is to be welded to a rigid support with three filler welds of leg length hmm, as shown in Figure It will support the weight of various components of a machine, as well as resist the extension load applied by a cylinder. The weight that is to be supported is N while the cylinder's action will add an additional N vertically downwards, such that the applied force will fluctuate from downwards to downwards. The location of the applied force is mm from the rigid support, as shown in the figure. The weld material will have a yield strength of MPa and an ultimate tensile strength of MPa. A factor of safety of is required.

a Using the 'welds as lines' method determine the position of the centroid of the weld group, the weld area, unit second moment of area, and full second moment of area in terms of where relevant

marks

b Determine the midrange and alternating components of force and the relationship between them. Assuming the weld contact at is imperfect, draw a suitably annotated diagram showing the weld group and the shear stresses experienced at locations A B Identify the weld location with the highest resultant stress, and justify your answer. Hence, determine the midrange and alternating components of primary and secondary shear stress that the weld will experience using a suitable stress concentration factor.

marks

c Determine the endurance strength of the weld material, and hence determine the weld height, using the modified Goodman criterion. What size would you specify on an engineering drawing?

marks

TOTAL MARKS

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock