Question: find the objective function (max or min) find the subject to (constraints) and non-negativity find slack and surplus variables Question 3: You work in a

find the objective function (max or min)

find the subject to (constraints) and non-negativity

find slack and surplus variables

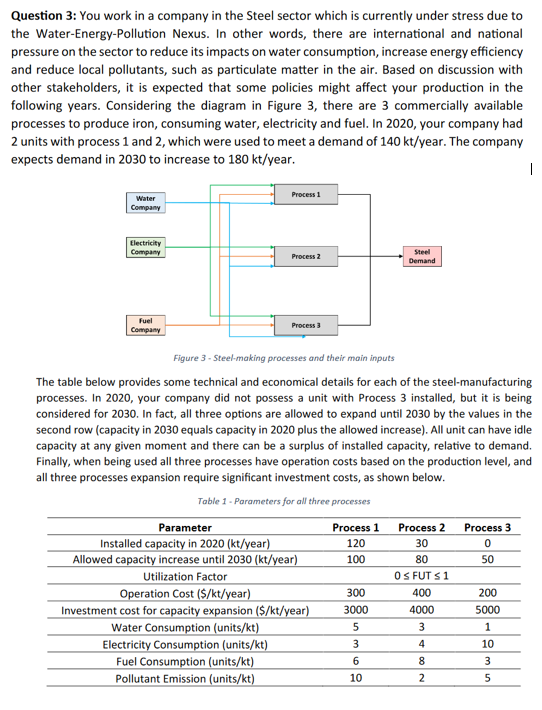

Question 3: You work in a company in the Steel sector which is currently under stress due to the Water-Energy-Pollution Nexus. In other words, there are international and national pressure on the sector to reduce its impacts on water consumption, increase energy efficiency and reduce local pollutants, such as particulate matter in the air. Based on discussion with other stakeholders, it is expected that some policies might affect your production in the following years. Considering the diagram in Figure 3, there are 3 commercially available processes to produce iron, consuming water, electricity and fuel. In 2020, your company had 2 units with process 1 and 2 , which were used to meet a demand of 140kt/year. The company expects demand in 2030 to increase to 180kt/ year. Figure 3 - Steel-making processes and their main inputs The table below provides some technical and economical details for each of the steel-manufacturing processes. In 2020, your company did not possess a unit with Process 3 installed, but it is being considered for 2030. In fact, all three options are allowed to expand until 2030 by the values in the second row (capacity in 2030 equals capacity in 2020 plus the allowed increase). All unit can have idle capacity at any given moment and there can be a surplus of installed capacity, relative to demand. Finally, when being used all three processes have operation costs based on the production level, and all three processes expansion require significant investment costs, as shown below. Table 1 - Parameters for all three processes Question 3: You work in a company in the Steel sector which is currently under stress due to the Water-Energy-Pollution Nexus. In other words, there are international and national pressure on the sector to reduce its impacts on water consumption, increase energy efficiency and reduce local pollutants, such as particulate matter in the air. Based on discussion with other stakeholders, it is expected that some policies might affect your production in the following years. Considering the diagram in Figure 3, there are 3 commercially available processes to produce iron, consuming water, electricity and fuel. In 2020, your company had 2 units with process 1 and 2 , which were used to meet a demand of 140kt/year. The company expects demand in 2030 to increase to 180kt/ year. Figure 3 - Steel-making processes and their main inputs The table below provides some technical and economical details for each of the steel-manufacturing processes. In 2020, your company did not possess a unit with Process 3 installed, but it is being considered for 2030. In fact, all three options are allowed to expand until 2030 by the values in the second row (capacity in 2030 equals capacity in 2020 plus the allowed increase). All unit can have idle capacity at any given moment and there can be a surplus of installed capacity, relative to demand. Finally, when being used all three processes have operation costs based on the production level, and all three processes expansion require significant investment costs, as shown below. Table 1 - Parameters for all three processes

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts