Question: Flexible Manufacturing System (Cost per minute) 1. Write an optimization model in general form to decide which products should be produced in the FMS to

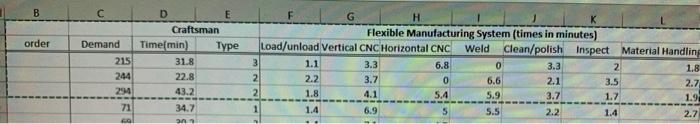

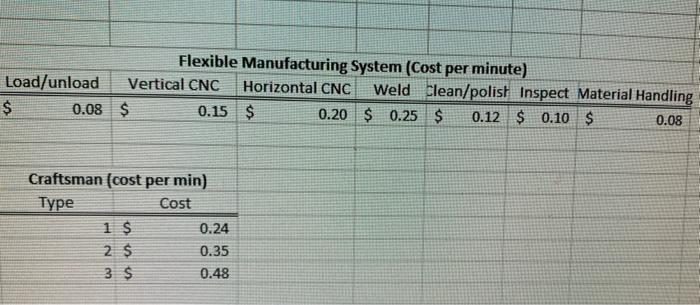

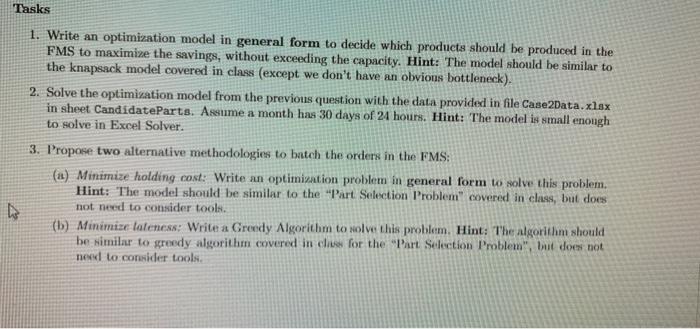

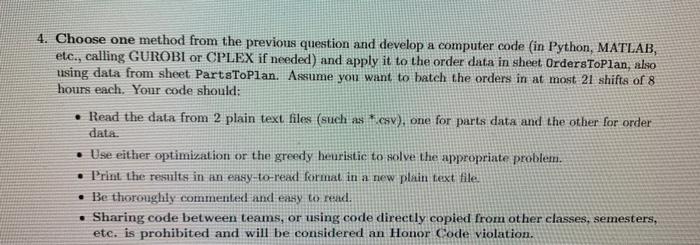

Flexible Manufacturing System (Cost per minute) 1. Write an optimization model in general form to decide which products should be produced in the FMS to maximize the savings, without exceeding the capacity. Hint: The model should be similar to the knapsack model covered in class (except we don't have an obvions bottleneck). 2. Solve the optimization model from the previous question with the data provided in file Case2Data. xlsx in sheet CandidateParts. Assume a month has 30 days of 24 hours. Hint: The model is small enough to solve in Excel Solver. 3. Propose two alternative methodologies to batch the orders in the FMS: (a) Minimize holding cost: Write an optimization problem in general form wo solve this problem. Hint: The model should be similar to the "Part Selection Problem" covered in class, but does not need to consider tools. (b) Minumize tateness: Write a Greedy Algorithm to solve this problem. Hint: The algorithm should be -rimilar to greedy atgorithm covered in chive for the "Part Selection Problem", bat does not nevi to consider tools. 4. Choose one method from the previous question and develop a computer code (in Python, MATLAB, etc., calling GUROBI or CPLEX if needed) and apply it to the order data in sheet OrdersToPlan, also using data from sheet PartsToPlan. Assume you want to batch the orders in at most 21 shifts of 8 hours each. Your code should: - Read the data from 2 plain text files (such as * csv), one for parts data and the other for order data. - Use either optimization or the greedy heuristic to solve the appropriate problem. - Print the results in an easy-to-read format in a new plain text file - Be thoroughily commented and easy to read. - Sharing code between teams, or using code directly copied from other classes, semesters, etc. is prohibited and will be considered an Honor Code violation. A manufacturing facility hus decided to purchase a new, top-of-the-line Flexible Maumufucturing System (FMS) to take over a large portion of the production of their widgets manufacturing operation. The company carrently makes all its products using a craftsman appronch, where a single worker makes each product from beginning to end. Each worker is paid for the time spent in production, and there are three different pay rates, depending on the worker's skill. The oompany has been in discuwations with geveral suppliers and have settled on a specific FMS ss the best option. This FMS has six itations, each one performing different trasks, and a materinl handing system. The supplier has estimated how much time would be required for ench widget at each station. Each station alio has an associated operating coct per minute. The attached file Cane2Data . xlax in sheet CandidateParto contains information on wach of the 80 cinclidite purts thint the cotupany bs considering to produce in the FMS. The data incladen average monthly dewand for wach part, current processing time per unit (in minutes), type of criftsman mpuimel, as well as the time required at ewch station of the FMS per unit (ako, in minutes). Separate tables in the mone shoet haw the opirating costs of each station of the FMS per minute and the nee mainule cont of evich type of criftamin. The company wints to we that information to deciele which parts to aseign to the niew FMS for production, considering they work three shifts of eight boum, seven days a week This will be the fint FMS that this manuficturer purchasies. Therefore, they are also lnterested in dewaloping a metbod for plauning production in the FMS. The company bornally plats- thelr produrtion weekly. The attadied tile Case2Data. xlix in sheec ParteToPLan eoilains information on 26 proifucts that ane represesitative of the types of parth thut the compary in likely in make in the FMS (rote, this bo not the and proment a regnirt with your lindlinge