Question: For problem #4, substitute the following values: plastic demand for 90-degree models change from 55 in year 3 to 68. This problem only focuses on

For problem #4, substitute the following values: plastic demand for 90-degree models change from 55 in year 3 to 68. This problem only focuses on the bronze and plastic machines and not the labor aspect. Comment on nay capacity shortfalls that you see. Show 'capacity' in units and capacity utilization as a percentage.

Solve #8

Solve the question below.

A retail store had sales of $46,341 in April and $56,000 in May. The store employs eight full-time workers who work a 40-hour week. In April, the store also had seven part-time workers at 10 hours per week, and in May the store had nine part-timers at 15 hours per week (assume four weeks in each month). Using sales dollars as the measure of output, what is the percentage change in productivity from Apil to May?

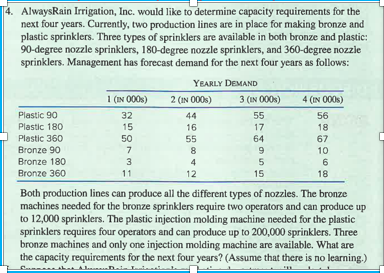

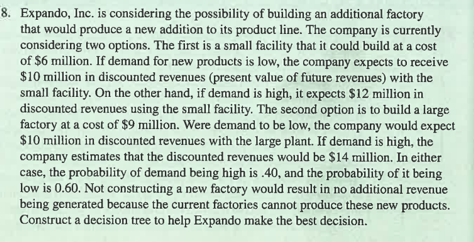

14. Always Rain Irrigation, Inc. would like to determine capacity requirements for the next four years. Currently, two production lines are in place for making bronze and plastic sprinklers. Three types of sprinklers are available in both bronze and plastic: 90-degree nozzle sprinklers, 180-degree nozzle sprinklers, and 360-degree nozzle sprinklers. Management has forecast demand for the next four years as follows: YEARLY DEMAND 1 (IN 000) 2 (IN 000) 3 (IN 000) 4 (IN 000) Plastic 90 32 44 55 56 Plastic 180 15 16 17 18 Plastic 360 50 55 64 67 Bronze 90 7 8 9 Bronze 180 3 4 5 6 Bronze 360 11 12 15 18 Both production lines can produce all the different types of nozzles. The bronze machines needed for the bronze sprinklers require two operators and can produce up to 12,000 sprinklers. The plastic injection molding machine needed for the plastic sprinklers requires four operators and can produce up to 200,000 sprinklers. Three bronze machines and only one injection molding machine are available. What are the capacity requirements for the next four years? (Assume that there is no learning.) 10 8. Expando, Inc. is considering the possibility of building an additional factory that would produce a new addition to its product line. The company is currently considering two options. The first is a small facility that it could build at a cost of $6 million. If demand for new products is low, the company expects to receive $10 million in discounted revenues (present value of future revenues) with the small facility. On the other hand, if demand is high, it expects $12 million in discounted revenues using the small facility. The second option is to build a large factory at a cost of $9 million. Were demand to be low, the company would expect $10 million in discounted revenues with the large plant. If demand is high, the company estimates that the discounted revenues would be $14 million. In either case, the probability of demand being high is .40, and the probability of it being low is 0.60. Not constructing a new factory would result in no additional revenue being generated because the current factories cannot produce these new products. Construct a decision tree to help Expando make the best decisionStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts