Question: Hello, can you please answer questions 1, a, 2, 3 ,4 Questions 1. How are the MOH costs currently calculated for the Chicago plant and

Hello, can you please answer questions 1, a, 2, 3 ,4

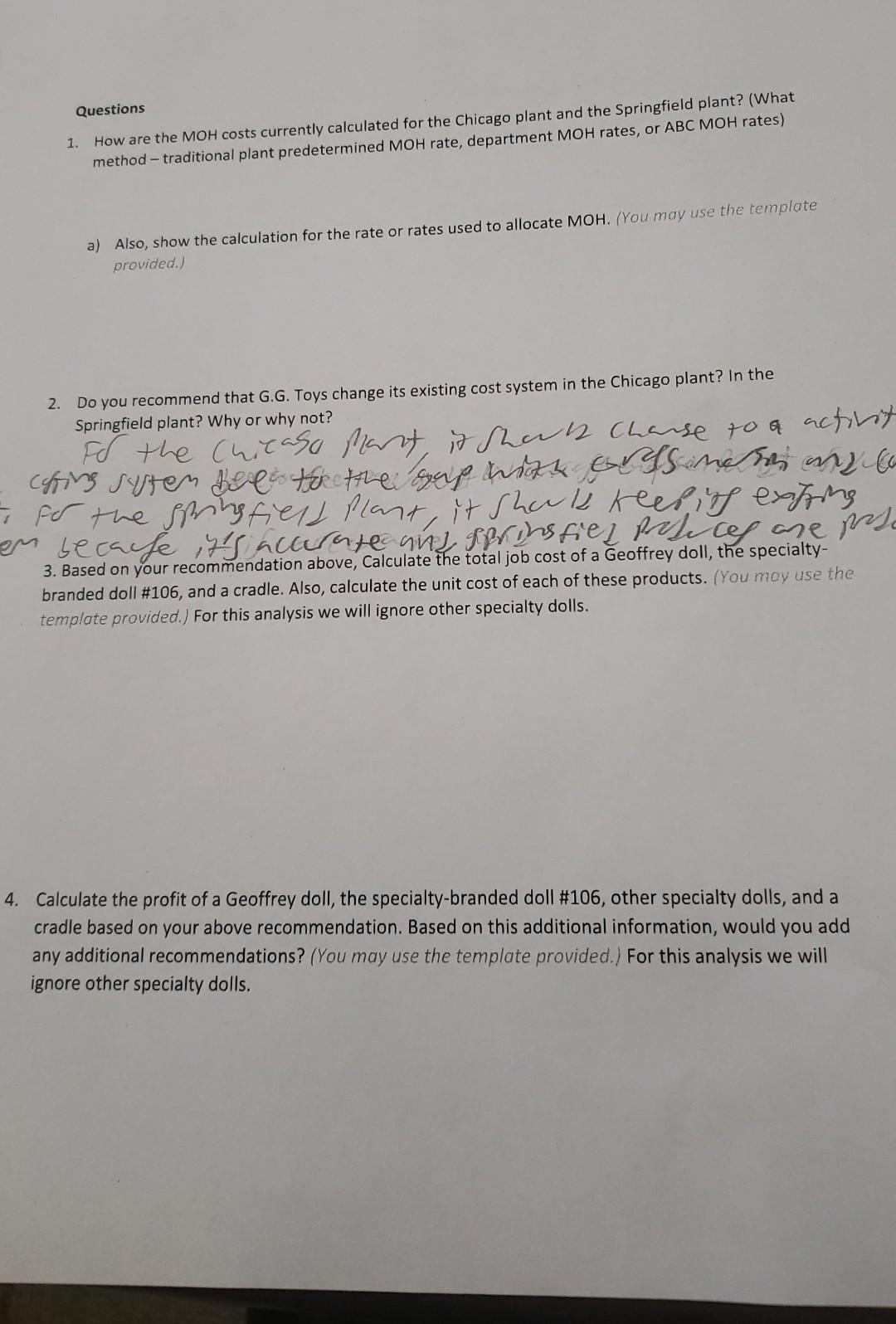

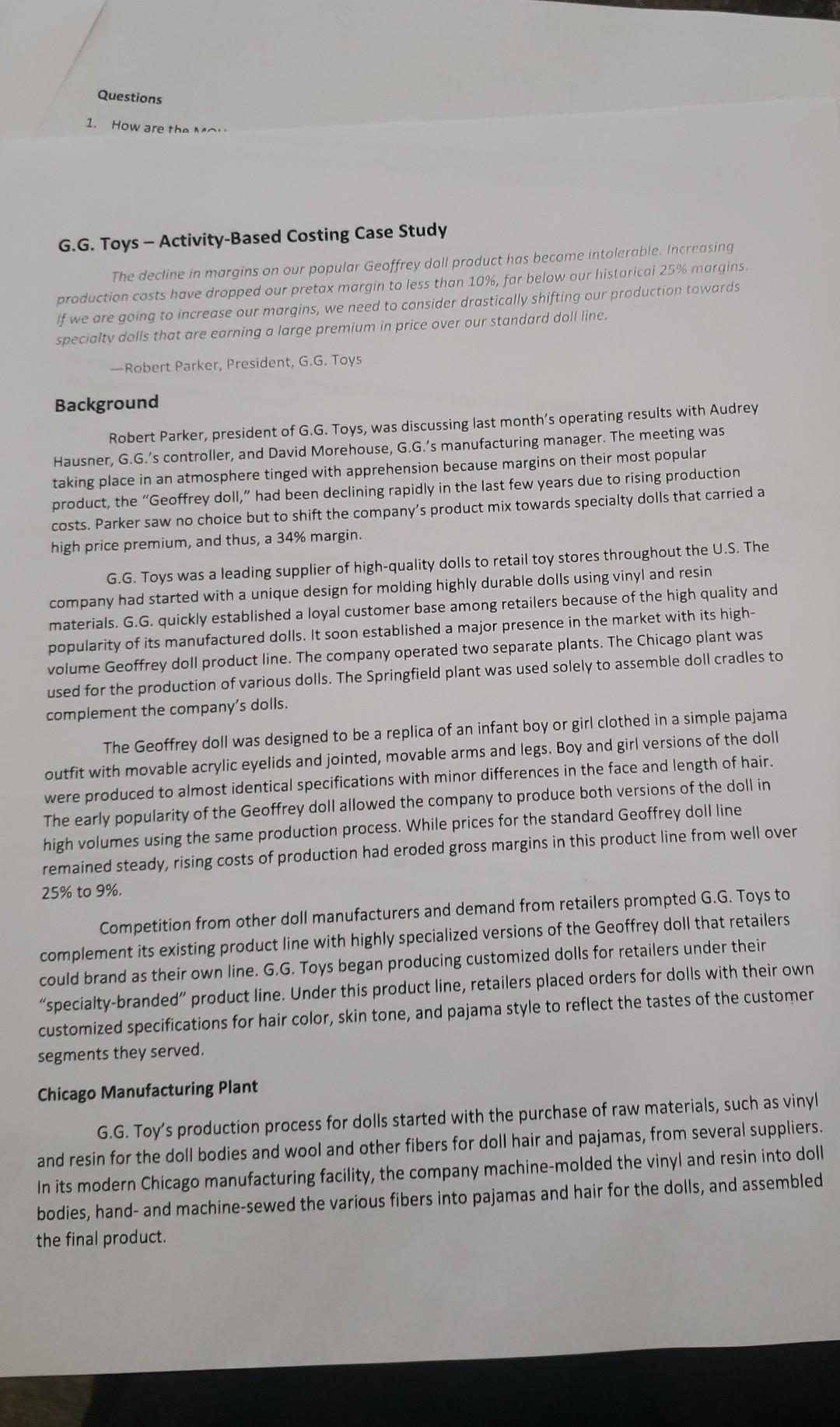

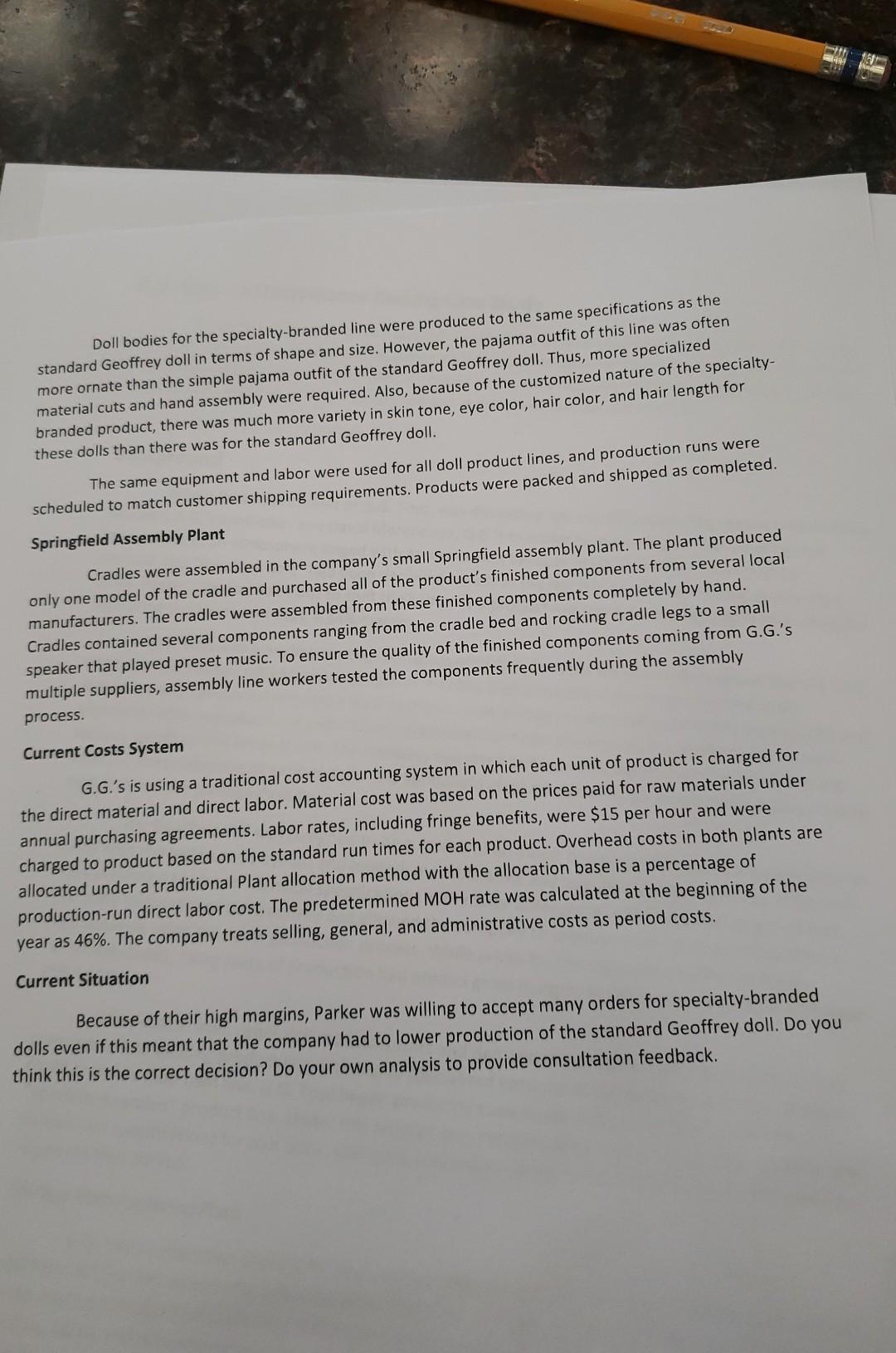

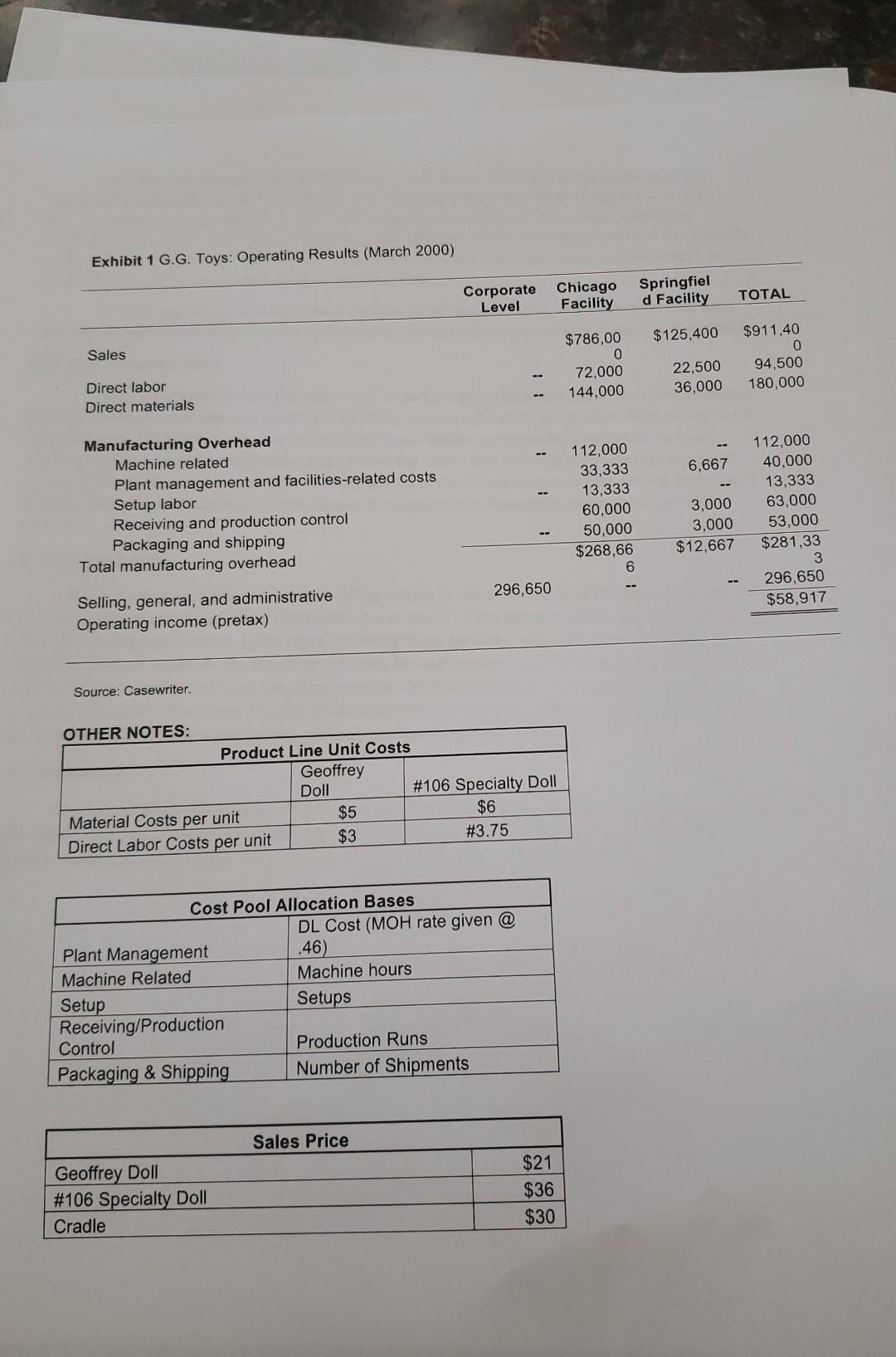

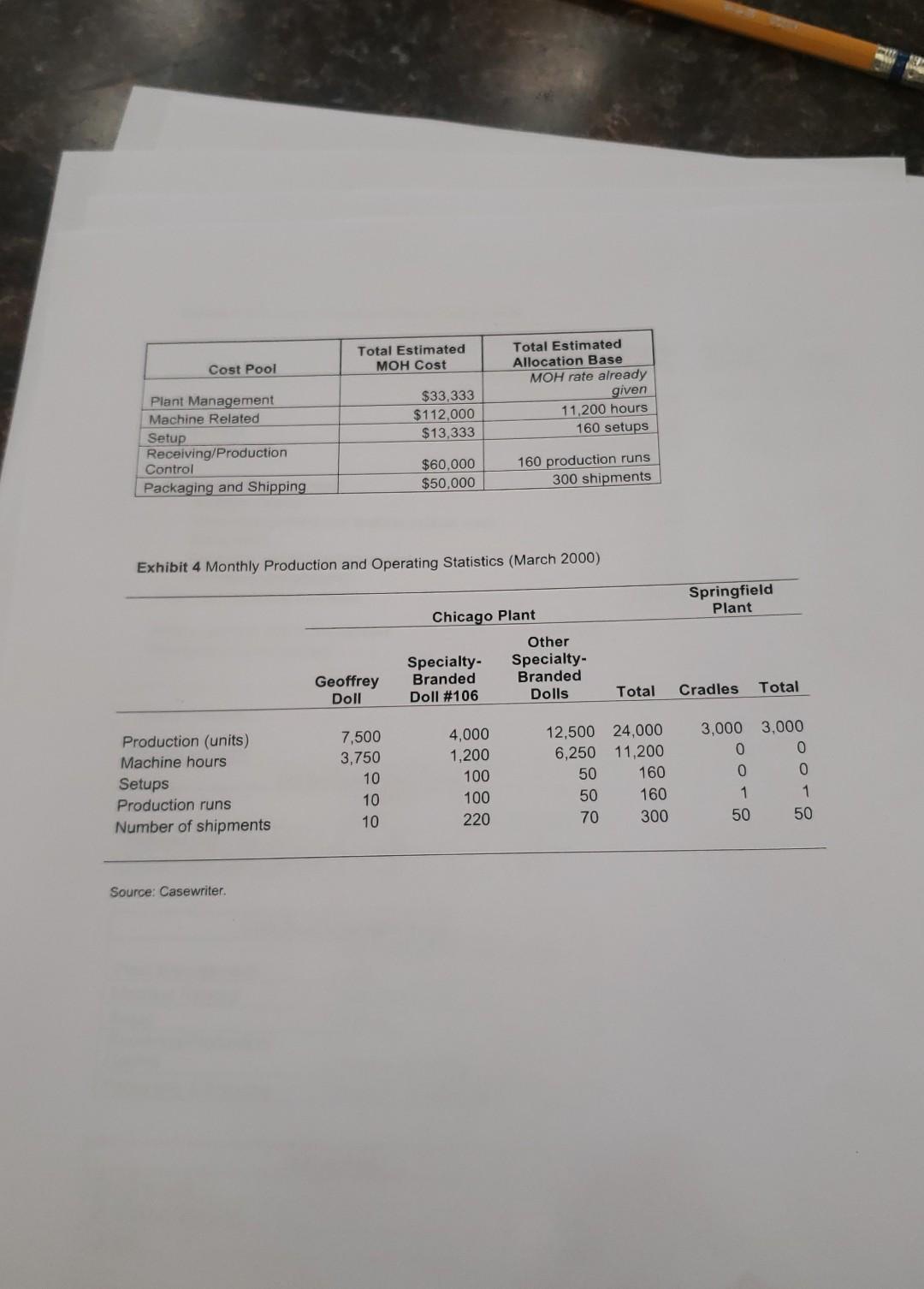

Questions 1. How are the MOH costs currently calculated for the Chicago plant and the Springfield plant? (What method - traditional plant predetermined MOH rate, department MOH rates, or ABCMOH rates) a) Also, show the calculation for the rate or rates used to allocate MOH. (You may use the template provided.) 2. Do you recommend that G.G. Toys change its existing cost system in the Chicago plant? In the Springfield plant? Why or why not? Fo the Chitaso phat it has ar charse to at ativ 3. Based on your recommendation above, Calculate the total job cost of a Geoffrey doll, the specialtybranded doll #106, and a cradle. Also, calculate the unit cost of each of these products. (You moy use the template provided.) For this analysis we will ignore other specialty dolls. 4. Calculate the profit of a Geoffrey doll, the specialty-branded doll #106, other specialty dolls, and a cradle based on your above recommendation. Based on this additional information, would you add any additional recommendations? (You may use the template provided.) For this analysis we will ignore other specialty dolls. G.G. Toys - Activity-Based Costing Case Study The decline in margins on our popular Geoffrey doll product has become intolerable. Increasing production costs have dropped our pretax margin to less than 10\%, far below our historicai 25% margins. If we are going to increase our margins, we need to consider drastically shifting our production towards specialty dolls that are earning a large premium in price over our standard doll line. Robert Parker, President, G.G. Toys Background Robert Parker, president of G.G. Toys, was discussing last month's operating results with Audrey Hausner, G.G.'s controller, and David Morehouse, G.G.'s manufacturing manager. The meeting was taking place in an atmosphere tinged with apprehension because margins on their most popular product, the "Geoffrey doll," had been declining rapidly in the last few years due to rising production costs. Parker saw no choice but to shift the company's product mix towards specialty dolls that carried a high price premium, and thus, a 34% margin. G.G. Toys was a leading supplier of high-quality dolls to retail toy stores throughout the U.S. The company had started with a unique design for molding highly durable dolls using vinyl and resin materials. G.G. quickly established a loyal customer base among retailers because of the high quality and popularity of its manufactured dolls. It soon established a major presence in the market with its highvolume Geoffrey doll product line. The company operated two separate plants. The Chicago plant was used for the production of various dolls. The Springfield plant was used solely to assemble doll cradles to complement the company's dolls. The Geoffrey doll was designed to be a replica of an infant boy or girl clothed in a simple pajama outfit with movable acrylic eyelids and jointed, movable arms and legs. Boy and girl versions of the doll were produced to almost identical specifications with minor differences in the face and length of hair. The early popularity of the Geoffrey doll allowed the company to produce both versions of the doll in high volumes using the same production process. While prices for the standard Geoffrey doll line remained steady, rising costs of production had eroded gross margins in this product line from well over 25% to 9%. Competition from other doll manufacturers and demand from retailers prompted G.G. Toys to complement its existing product line with highly specialized versions of the Geoffrey doll that retailers could brand as their own line. G.G. Toys began producing customized dolls for retailers under their "specialty-branded" product line. Under this product line, retailers placed orders for dolls with their own customized specifications for hair color, skin tone, and pajama style to reflect the tastes of the customer segments they served. Chicago Manufacturing Plant G.G. Toy's production process for dolls started with the purchase of raw materials, such as vinyl and resin for the doll bodies and wool and other fibers for doll hair and pajamas, from several suppliers. In its modern Chicago manufacturing facility, the company machine-molded the vinyl and resin into doll bodies, hand- and machine-sewed the various fibers into pajamas and hair for the dolls, and assembled the final product. Doll bodies for the specialty-branded line were produced to the same specifications as the standard Geoffrey doll in terms of shape and size. However, the pajama outfit of this line was often more ornate than the simple pajama outfit of the standard Geoffrey doll. Thus, more specialized material cuts and hand assembly were required. Also, because of the customized nature of the specialtybranded product, there was much more variety in skin tone, eye color, hair color, and hair length for these dolls than there was for the standard Geoffrey doll. The same equipment and labor were used for all doll product lines, and production runs were scheduled to match customer shipping requirements. Products were packed and shipped as completed. Springfield Assembly Plant Cradles were assembled in the company's small Springfield assembly plant. The plant produced only one model of the cradle and purchased all of the product's finished components from several local manufacturers. The cradles were assembled from these finished components completely by hand. Cradles contained several components ranging from the cradle bed and rocking cradle legs to a small speaker that played preset music. To ensure the quality of the finished components coming from G.G.'s multiple suppliers, assembly line workers tested the components frequently during the assembly process. Current Costs System G.G.'s is using a traditional cost accounting system in which each unit of product is charged for the direct material and direct labor. Material cost was based on the prices paid for raw materials under annual purchasing agreements. Labor rates, including fringe benefits, were $15 per hour and were charged to product based on the standard run times for each product. Overhead costs in both plants are allocated under a traditional Plant allocation method with the allocation base is a percentage of production-run direct labor cost. The predetermined MOH rate was calculated at the beginning of the year as 46%. The company treats selling, general, and administrative costs as period costs. Current Situation Because of their high margins, Parker was willing to accept many orders for specialty-branded dolls even if this meant that the company had to lower production of the standard Geoffrey doll. Do you think this is the correct decision? Do your own analysis to provide consultation feedback. Exhibit 1 G.G. Toys: Operating Results (March 2000) Source: Casewriter. Exhibit 4 Monthly Production and Operating Statistics (March 2000) Source: Casewriter

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts