Question: hello please can you solve it the dead line is tmorrow ! 3- The table below lists the work elements (in minutes) to be performed

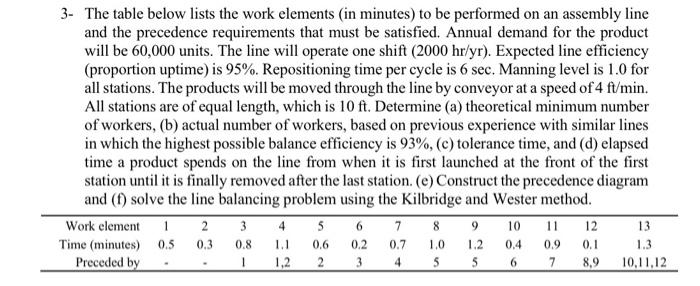

3- The table below lists the work elements (in minutes) to be performed on an assembly line and the precedence requirements that must be satisfied. Annual demand for the product will be 60,000 units. The line will operate one shift (2000hr/yr). Expected line efficiency (proportion uptime) is 95%. Repositioning time per cycle is 6 sec. Manning level is 1.0 for all stations. The products will be moved through the line by conveyor at a speed of 4ft/min. All stations are of equal length, which is 10ft. Determine (a) theoretical minimum number of workers, (b) actual number of workers, based on previous experience with similar lines in which the highest possible balance efficiency is 93%, (c) tolerance time, and (d) elapsed time a product spends on the line from when it is first launched at the front of the first station until it is finally removed after the last station. (e) Construct the precedence diagram and (f) solve the line balancing problem using the Kilbridge and Wester method

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts