Question: Help Inventory control Solve it now please I need it This information is complete This is all my homework ! Exercise 3.2 - Lot Sizing

Help

Inventory control

Solve it now please I need it

This information is complete

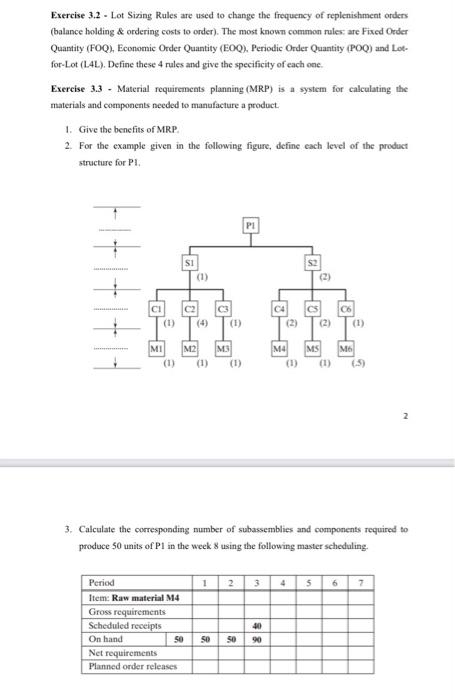

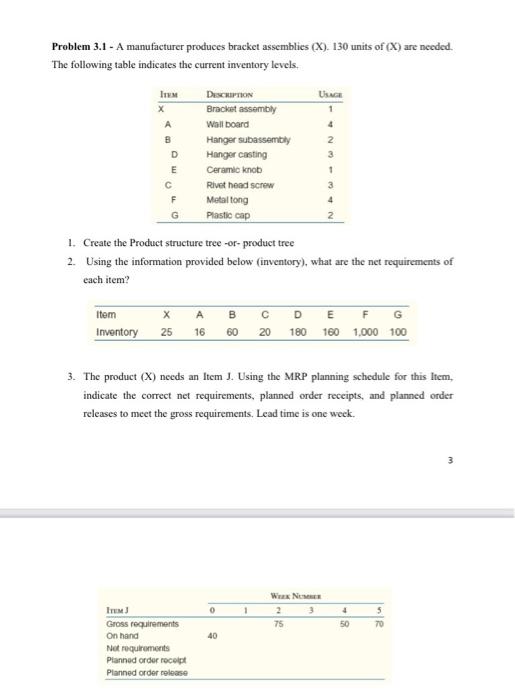

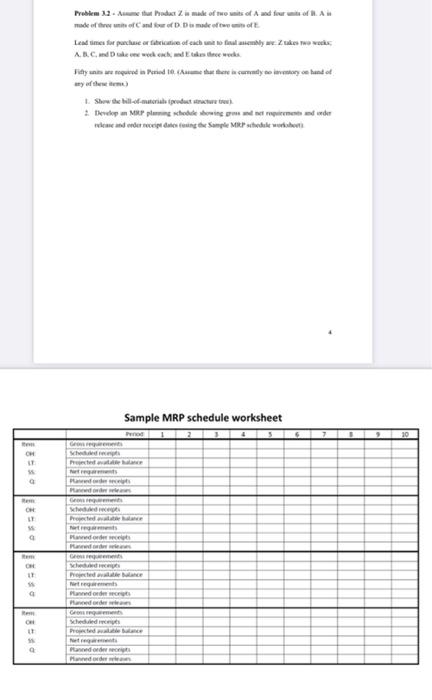

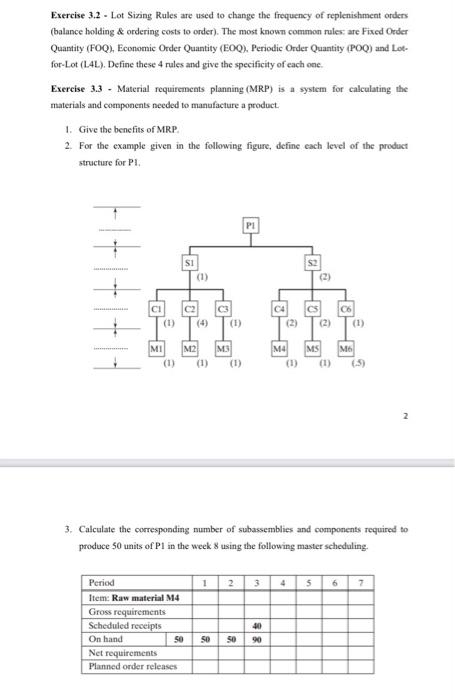

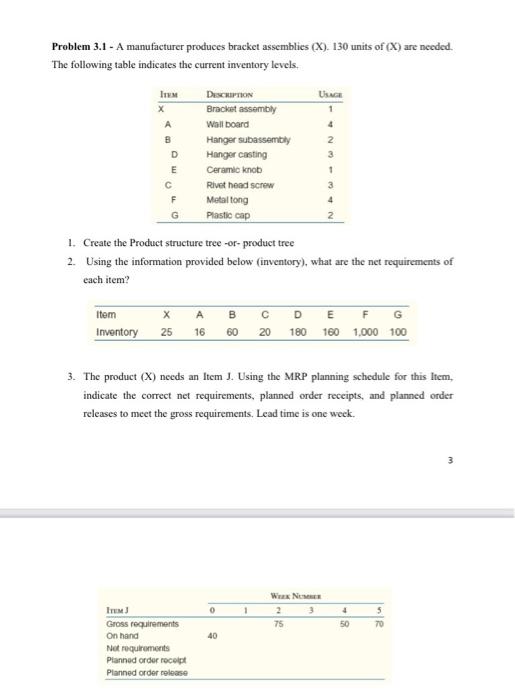

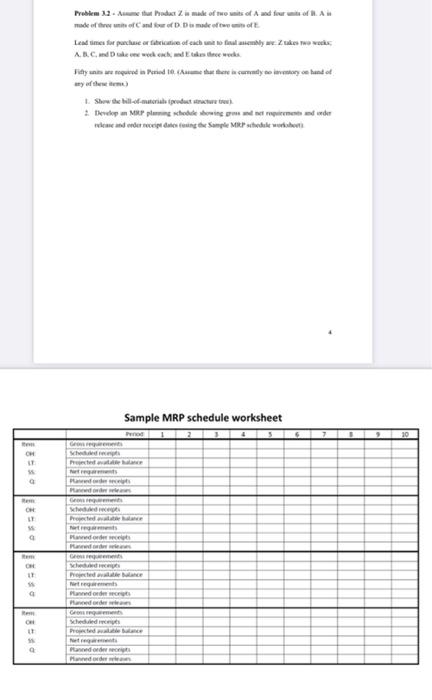

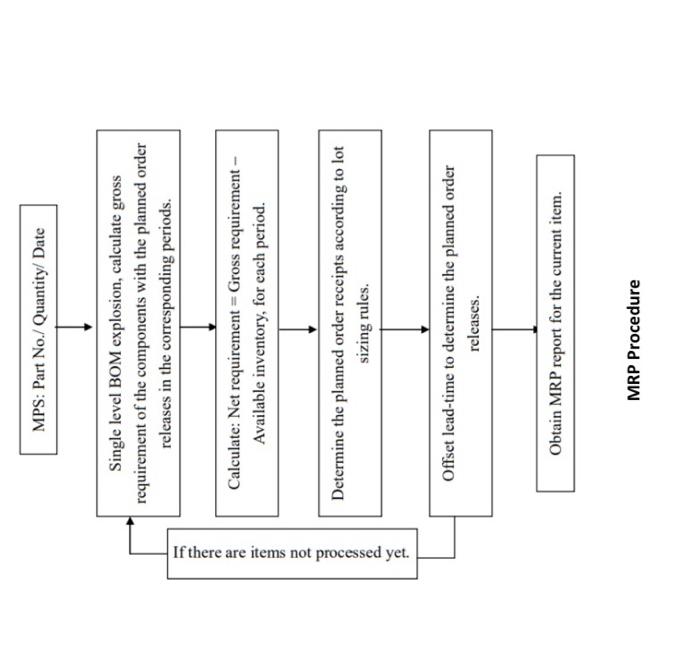

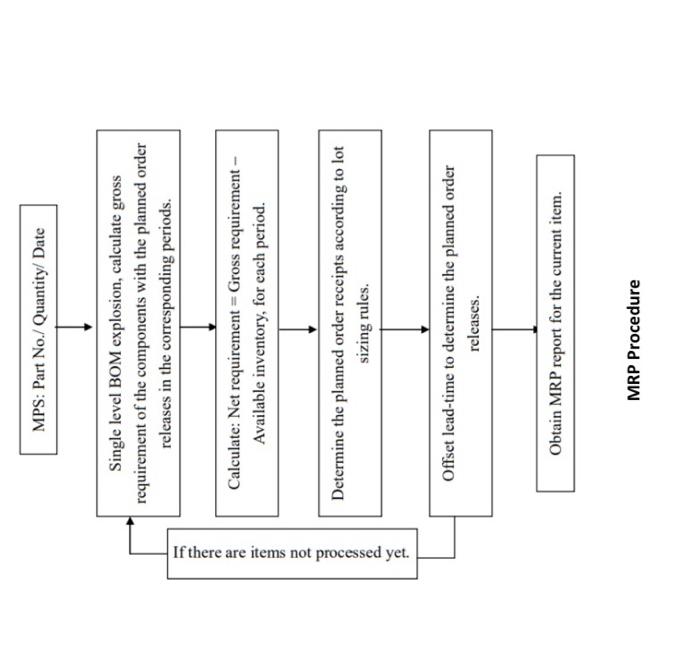

Exercise 3.2 - Lot Sizing Rules are used to change the frequency of replenishment orders (balance holding & ordering costs to order). The most known common rules: are Fixed Order Quantity (FOQ), Economic Order Quantity (EOQ), Periodic Order Quantity (POQ) and Lotfor-Lot (L4L). Define these 4 rules and give the specificity of each one. Exercise 3.3 - Material requirements planning (MRP) is a system for calculating the materials and components needed to manufacture a product. 1. Give the benefits of MRP. 2. For the example given in the following figure, define each level of the product structure for Pl. 3. Calculate the corresponding number of subassemblies and components required to produce 50 units of Pl in the week 8 using the following master scheduling. Problem 3.1 - A manufacturer produces bracket assemblies (X). 130 units of (X) are needed. The following table indicates the current inventory levels, 1. Create the Product structure tree -or-product tree 2. Using the information provided below (inventory), what are the net requirements of each item? 3. The product (X) needs an Item J. Using the MRP planning schedule for this ltem, indicate the correct net requirements, planned order reccipts, and planned order releases to meet the gross requirements. Lead time is one week. aty of then aterne.) Sample MRP schedule worksheet MPS: Part No./ Quantity/ Date MRP Procedure This is all my homework !

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock