Question: Her operations manager is considering a new plan, which begins in January with 200 units on hand and ends with zero inventory. Stockout cost of

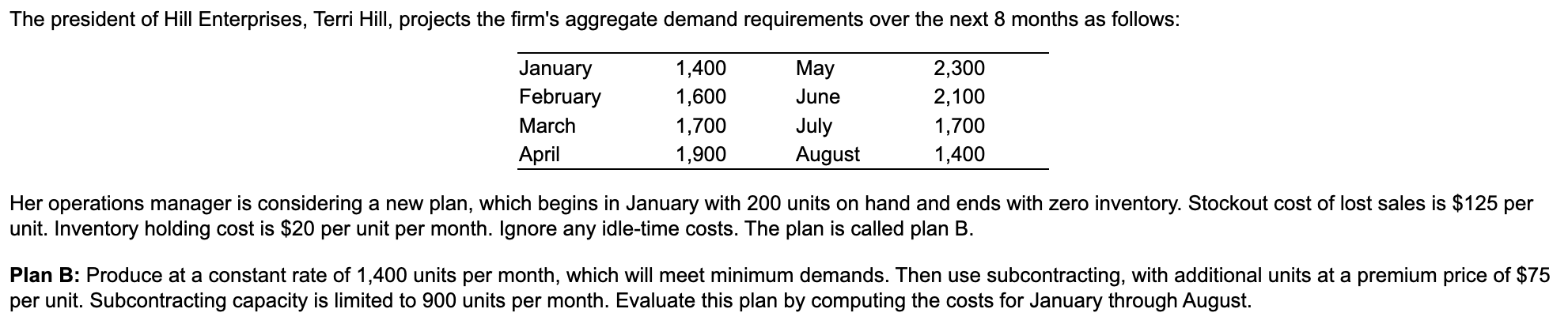

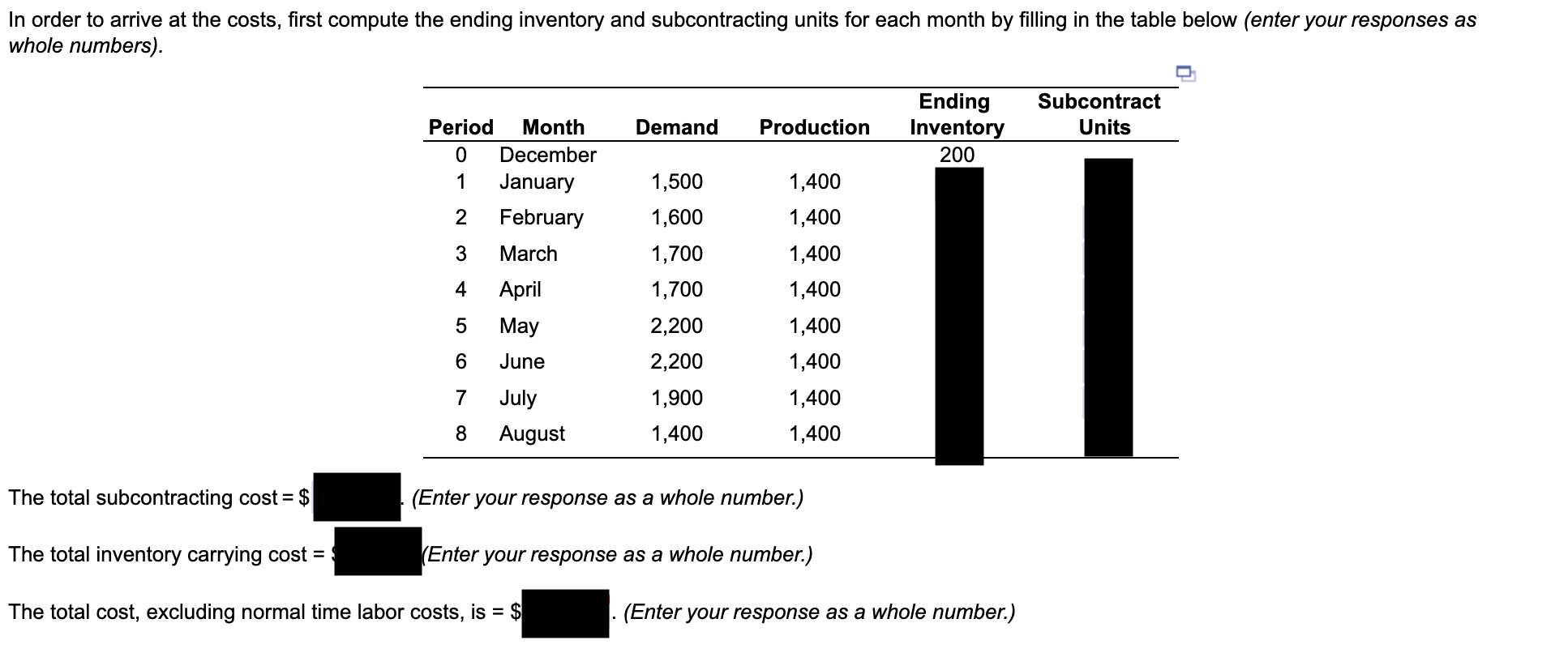

Her operations manager is considering a new plan, which begins in January with 200 units on hand and ends with zero inventory. Stockout cost of lost sales is $125 per unit. Inventory holding cost is $20 per unit per month. Ignore any idle-time costs. The plan is called plan B. Plan B: Produce at a constant rate of 1,400 units per month, which will meet minimum demands. Then use subcontracting, with additional units at a premium price of $75 per unit. Subcontracting capacity is limited to 900 units per month. Evaluate this plan by computing the costs for January through August. The total subcontracting cost =$ (Enter your response as a whole number.) The total inventory carrying cost = 'Enter your response as a whole number.) The total cost, excluding normal time labor costs, is =9 (Enter your response as a whole number.) Her operations manager is considering a new plan, which begins in January with 200 units on hand and ends with zero inventory. Stockout cost of lost sales is $125 per unit. Inventory holding cost is $20 per unit per month. Ignore any idle-time costs. The plan is called plan B. Plan B: Produce at a constant rate of 1,400 units per month, which will meet minimum demands. Then use subcontracting, with additional units at a premium price of $75 per unit. Subcontracting capacity is limited to 900 units per month. Evaluate this plan by computing the costs for January through August. The total subcontracting cost =$ (Enter your response as a whole number.) The total inventory carrying cost = 'Enter your response as a whole number.) The total cost, excluding normal time labor costs, is =9 (Enter your response as a whole number.)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts