Question: Homework 1 Question ss-1 and Question 1-1 (b, c, d, f, j), 1-4, 1-8, 1-20 in Page 41-46 Q. 1-1: Consider the following organizations. How

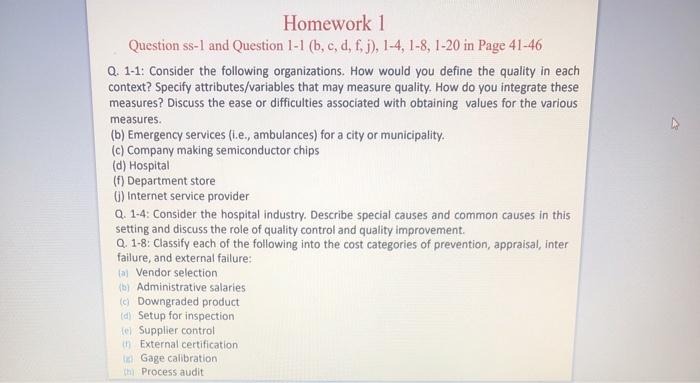

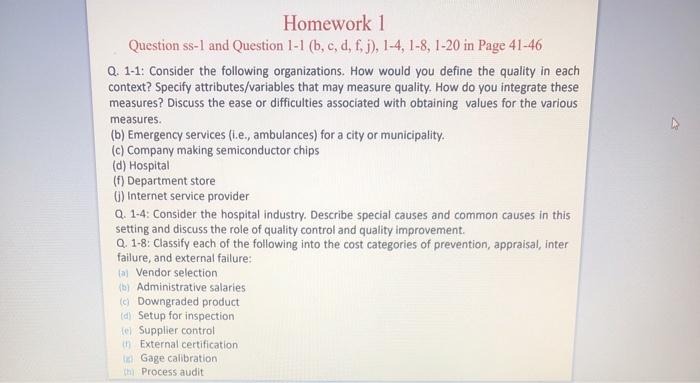

Homework 1 Question ss-1 and Question 1-1 (b, c, d, f, j), 1-4, 1-8, 1-20 in Page 41-46 Q. 1-1: Consider the following organizations. How would you define the quality in each context? Specify attributes/variables that may measure quality. How do you integrate these measures? Discuss the ease or difficulties associated with obtaining values for the various measures. (b) Emergency services (i.e., ambulances) for a city or municipality. (c) Company making semiconductor chips (d) Hospital (f) Department store (j) Internet service provider Q. 1-4: Consider the hospital industry. Describe special causes and common causes in this setting and discuss the role of quality control and quality improvement. Q. 1-8: Classify each of the following into the cost categories of prevention, appraisal, inter failure, and external failure: (a) Vendor selection (b) Administrative salaries (c) Downgraded product (d) Setup for inspection (e) Supplier control (f) External certification (g) Gage calibration (h) Process audit

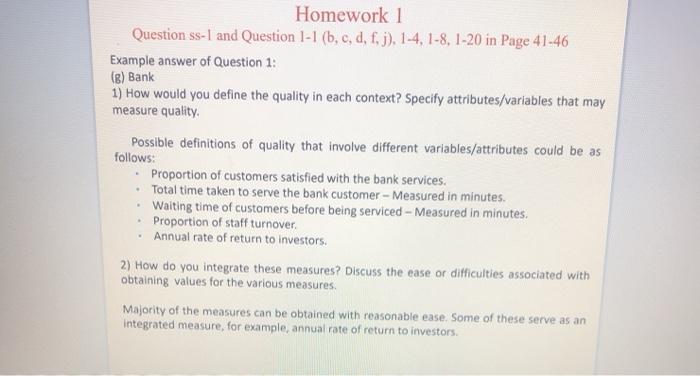

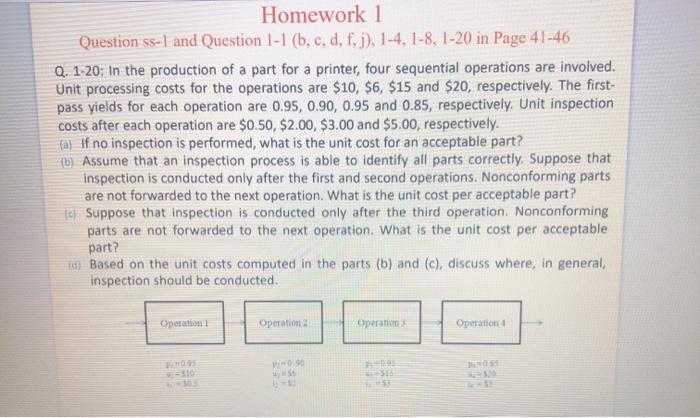

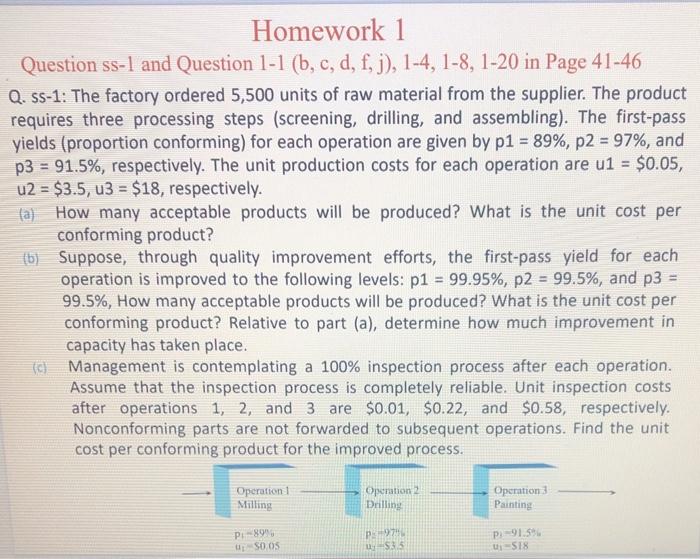

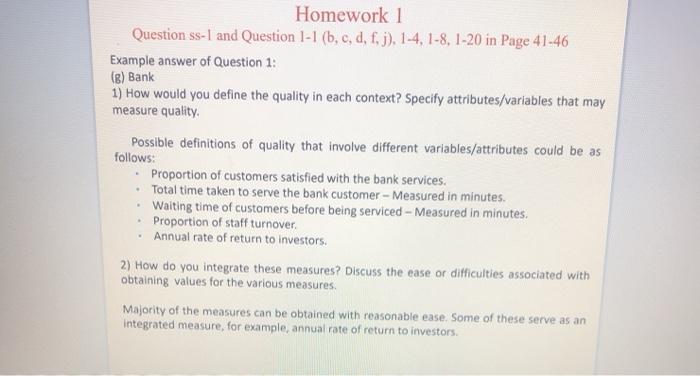

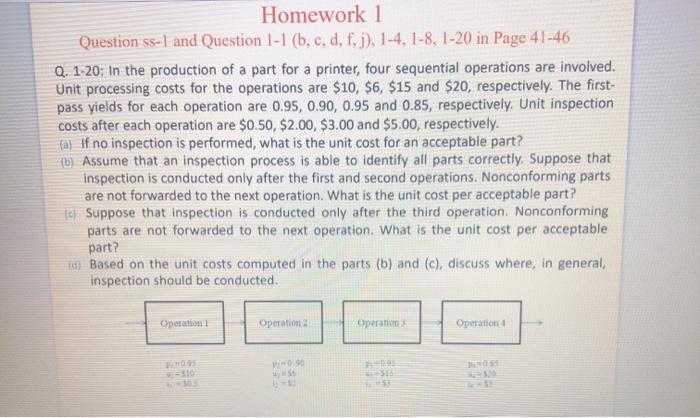

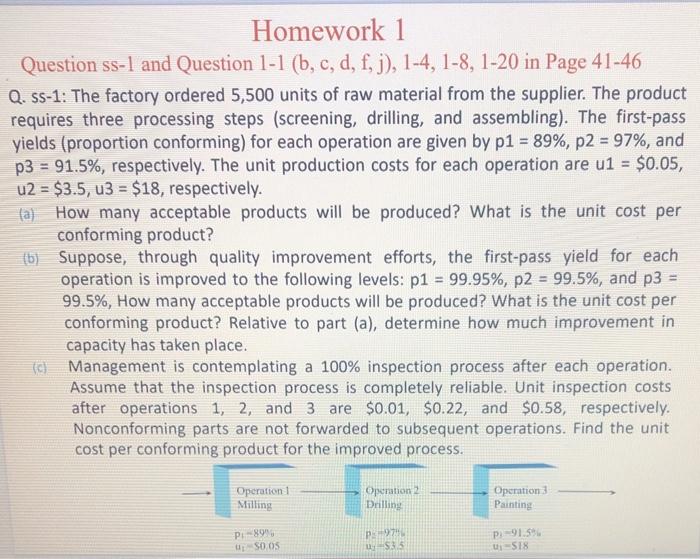

Homework 1 Question ss-I and Question 1-1 (b, c, d, f, j), 1-4, 1-8, 1-20 in Page 41-46 Q. 1-1: Consider the following organizations. How would you define the quality in each context? Specify attributes/variables that may measure quality. How do you integrate these measures? Discuss the ease or difficulties associated with obtaining values for the various measures. (b) Emergency services (i.e., ambulances) for a city or municipality. (c) Company making semiconductor chips (d) Hospital (f) Department store G) Internet service provider Q. 1-4: Consider the hospital industry. Describe special causes and common causes in this setting and discuss the role of quality control and quality improvement Q. 1-8: Classify each of the following into the cost categories of prevention, appraisal, inter failure, and external failure: a Vendor selection (b) Administrative salaries Downgraded product (d) Setup for inspection 101 Supplier control in External certification Gage calibration Process audit Homework 1 Question ss-I and Question 1-1 (b, c, d, f,j), 1-4, 1-8, 1-20 in Page 41-46 Example answer of Question 1: (B) Bank 1) How would you define the quality in each context? Specify attributes/variables that may measure quality Possible definitions of quality that involve different variables/attributes could be as follows: Proportion of customers satisfied with the bank services. Total time taken to serve the bank customer - Measured in minutes. Waiting time of customers before being serviced - Measured in minutes. Proportion of staff turnover. Annual rate of return to investors. 2) How do you integrate these measures? Discuss the ease or difficulties associated with obtaining values for the various measures . Majority of the measures can be obtained with reasonable ease. Some of these serve as an integrated measure, for example, annual rate of return to investors. Homework 1 Question ss-1 and Question 1-1 (b, c, d, f,j), 1-4, 1-8, 1-20 in Page 41-46 Q. 1-20: In the production of a part for a printer, four sequential operations are involved. Unit processing costs for the operations are $10, $6, $15 and $20, respectively. The first- pass yields for each operation are 0.95, 0.90, 0.95 and 0.85, respectively. Unit inspection costs after each operation are $0.50, $2.00, $3.00 and $5.00, respectively. (a) If no inspection is performed, what is the unit cost for an acceptable part? (b) Assume that an inspection process is able to identify all parts correctly. Suppose that inspection is conducted only after the first and second operations. Nonconforming parts are not forwarded to the next operation. What is the unit cost per acceptable part? te) Suppose that inspection is conducted only after the third operation. Nonconforming parts are not forwarded to the next operation. What is the unit cost per acceptable part? in Based on the unit costs computed in the parts (b) and (c), discuss where, in general, inspection should be conducted. Operation 1 Operation Operation Operation Homework 1 Question ss-1 and Question 1-1 (b, c, d, f,j), 1-4, 1-8, 1-20 in Page 41-46 Q. 55-1: The factory ordered 5,500 units of raw material from the supplier. The product requires three processing steps (screening, drilling, and assembling). The first-pass yields (proportion conforming) for each operation are given by p1 = 89%, p 2 = 97%, and p3 = 91.5%, respectively. The unit production costs for each operation are u1 = $0.05, u2 = $3.5, u3 = $18, respectively. How many acceptable products will be produced? What is the unit cost per conforming product? (b) Suppose, through quality improvement efforts, the first-pass yield for each operation is improved to the following levels: p1 = 99.95%, p2 = 99.5%, and p3 99.5%, How many acceptable products will be produced? What is the unit cost per conforming product? Relative to part (a), determine how much improvement in capacity has taken place. to Management is contemplating a 100% inspection process after each operation. Assume that the inspection process is completely reliable. Unit inspection costs after operations 1, 2, and 3 are $0.01, $0.22, and $0.58, respectively. Nonconforming parts are not forwarded to subsequent operations. Find the unit cost per conforming product for the improved process. Operation 1 Milling Operation 2 Drilling Operation 3 Painting PL-899 u SOOS PE 97 533 P-91.5% USIS