Question: I know this question is already solved but it's not solved like the way I wanted it to be...Can You solve it by showing the

I know this question is already solved but it's not solved like the way I wanted it to be...Can You solve it by showing the Block Flow diagram and the solutions or values for the unknowns of components and mass flowrate in all the streams? Thank you

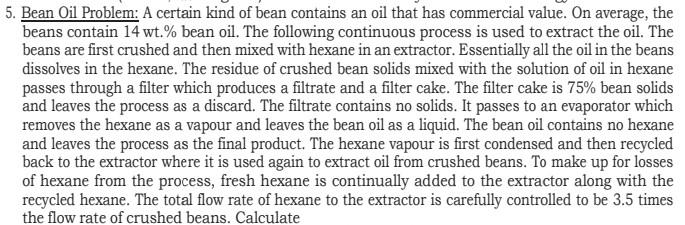

5. Bean Oil Problem: A certain kind of bean contains an oil that has commercial value. On average, the beans contain 14 wt.% bean oil. The following continuous process is used to extract the oil. The beans are first crushed and then mixed with hexane in an extractor. Essentially all the oil in the beans dissolves in the hexane. The residue of crushed bean solids mixed with the solution of oil in hexane passes through a filter which produces a filtrate and a filter cake. The filter cake is 75% bean solids and leaves the process as a discard. The filtrate contains no solids. It passes to an evaporator which removes the hexane as a vapour and leaves the bean oil as a liquid. The bean oil contains no hexane and leaves the process as the final product. The hexane vapour is first condensed and then recycled back to the extractor where it is used again to extract oil from crushed beans. To make up for losses of hexane from the process, fresh hexane is continually added to the extractor along with the recycled hexane. The total flow rate of hexane to the extractor is carefully controlled to be 3.5 times the flow rate of crushed beans. Calculate

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts