Question: I need help to answer this questions using that article, with introduction, 3 body paragraphs and conclusion. Using 2 reference from books,journal/periodical articles. What cause

I need help to answer this questions using that article, with introduction, 3 body paragraphs and conclusion. Using 2 reference from books,journal/periodical articles. What cause the defect? What allowed the defect to escape detection? What in the quality management system failed to consider this to begin with?

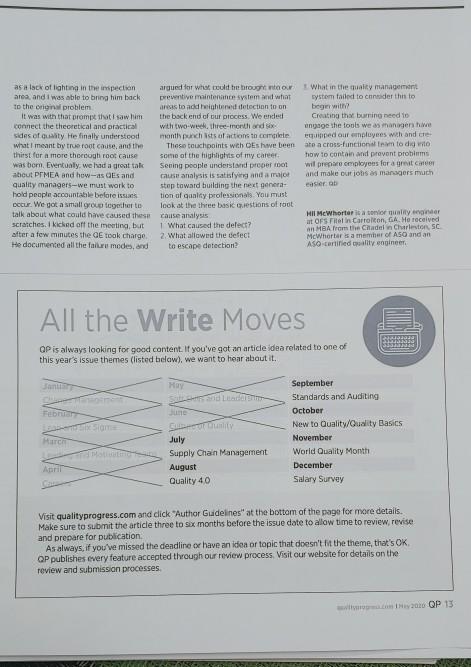

Personal stories from quality professionals MY QUALITY STORY TRAINING Training Tomorrow's Quality Professionals Help the next generation connect the thearetical and practical sides of quality by Hi Whortor After working for a cable manufacturer the cable. Upon receiving the cable, my conditions could be different between for a few years, I've learned that there junior quality engineer (OE) did his own how the customer was conducting its are more than 100 failure modes that evaluation of the product but could not analysis and what we were doing. can occur at an extruder head, which is find anything wrong. He went over every The junior OE decided to roll the cable one small part of a much larger process. inch of the cable, but couldn't pinpoint into the lab, which had more intense When my team encountered scratches a single blemish For every 10 meters ar lighting, and check it again. This time on a cable, our new process failure cable he pulled off, he convinced himself he came back ghost white, realizing he mode and effects analyses (PFMEA) inore and more of the customer's blur had almost inade a mistake. Under the showed that there are more than 600 der in sending back what appeared, to better lighting, he was able to see the possible causes for a potential straight him to be perfectly acceptable product scratches the customer was complaining line scratch. And with a line running The junior GE fully documented his about. The junior OE wrote the correc- at 800 meters per minute. it is nearly findings and had the process engineer tive action and listed his only root cause impossible to see the scratches happen look at the cable to validate that nothing ing in process was wrong with the product from our This is what happened. An interna company. He was about to email the Seeing people understand proper tional customer reported scratches customer, declaring there was nothing root cause analysis is satisfying on a cable. The customer took pic wrong, when I asked him why the cus- and a major step toward building tures, which showed the cuts were in tomer would see scratches but we would the next generation of quality a perfectly straight line and returned not. We hypothesized about how the professionals 12 OP 200 m as a lack of lighting in the inspection argued for what could be brougWhat in the quality management area, and I was able to bring him back preventive maintenance system and what system failed to consider this to to the original problem areas to add heightened detection to on bege mit It was with that prompt that saw him the backend of our process. We ended Creating that burning need to connect the theoretical and practical with two-wech, three month and six engage the foot we as managers the sides of quality He finally understood monthpuchists of actions to comete equipped our employees with and the What meant by true root cause, and the These touchpoints with Es have been ato a cross-functional to dow thirst for a more thorough root cause Some of the highlights of my career how to contain and provont problems was born. Eventually, we had a great tok Sening people understand proper tot wil omployees for a great about PIMEA and how-as Qes and Cause analysis is satisfying and a major and make out jobs as managers much quality managers-we must work to step toward building the next genera easier hold people accountable before it's tion of anlity professionals. You must occur. We got a small group together to look at the three bask Guestions of root talk about what could have caused these cause analysis Hll Me Whorteris oor my onder scratches. I kicked off the meeting, but 1 What caused the defect? at OFS Fittin Carrolcon, GA He received after a few minutes the took charge an MBA from the Chadeln Charleston, SC 2. What allowed the defect McWhorter is a member of ASO and an He documented all the failure modes, and to escape detection? ASO certified ality engineer All the Write Moves QP is always looking for good content. If you've got an artide idea related to one of this year's issue themes (listed below), we want to hear about it. an Sune ES September Standards and Auditing October New to Quality/Quality Basics November World Quality Month December Salary Survey March July Supply Chain Management August Quality 40 Visit qualityprogress.com and click "Author Guidelines" at the bottom of the page for more details. Make sure to submit the article three to six months before the issue date to allow time to review revise and prepare for publication As always, if you ve missed the deadline or have an idea or topic that doesn't fit the theme, that's OK QP publishes every feature accepted through our review process. Visit our website for details on the review and submission processes 2010 QP 13Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts