Question: I need help with the assignments for Problems 1&2 please. Thanks in advance! Sample-Size Considerations PART 1 WT Corporation manufactures crankshafts for 2-L auto- motive

I need help with the assignments for Problems 1&2 please. Thanks in advance!

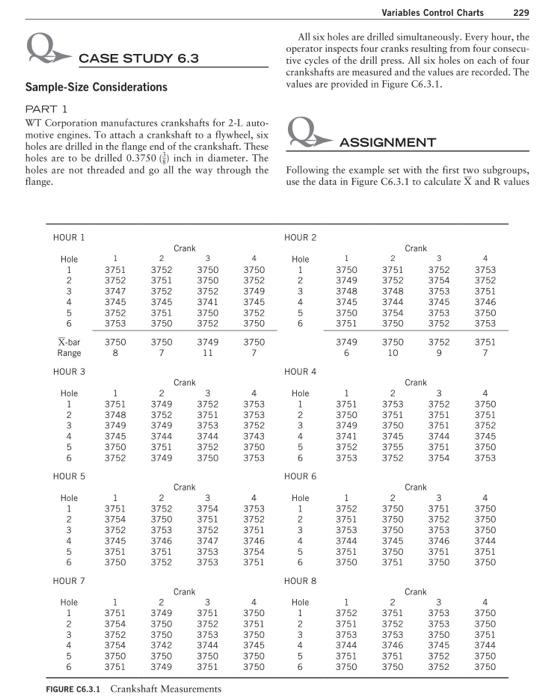

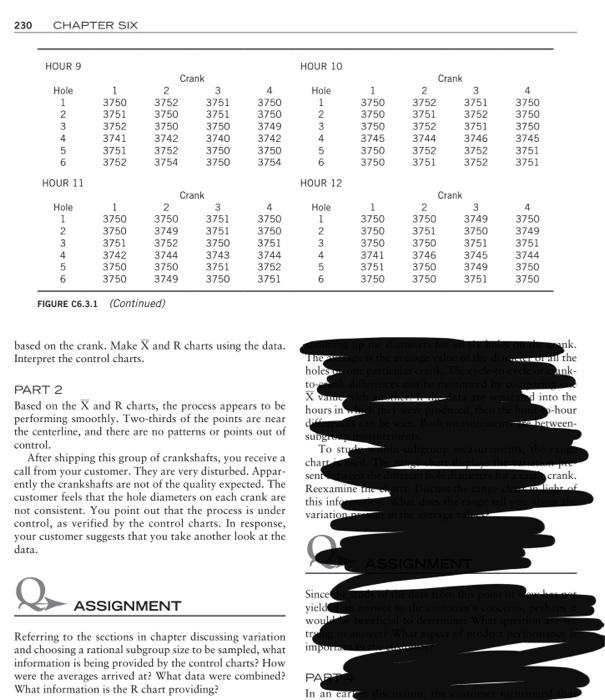

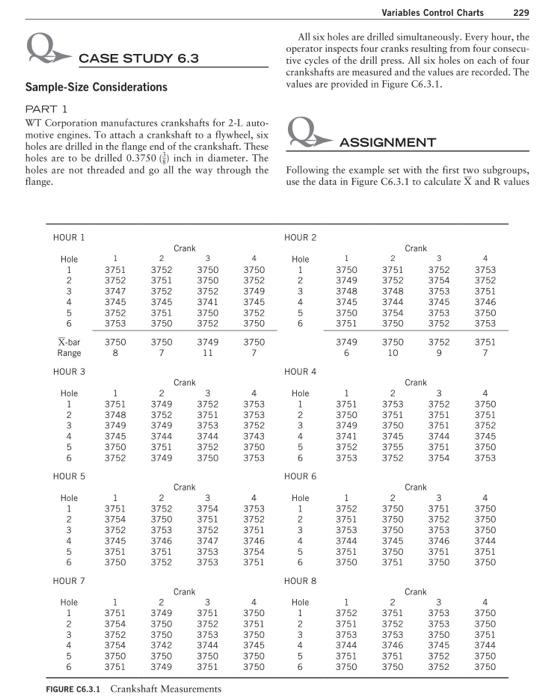

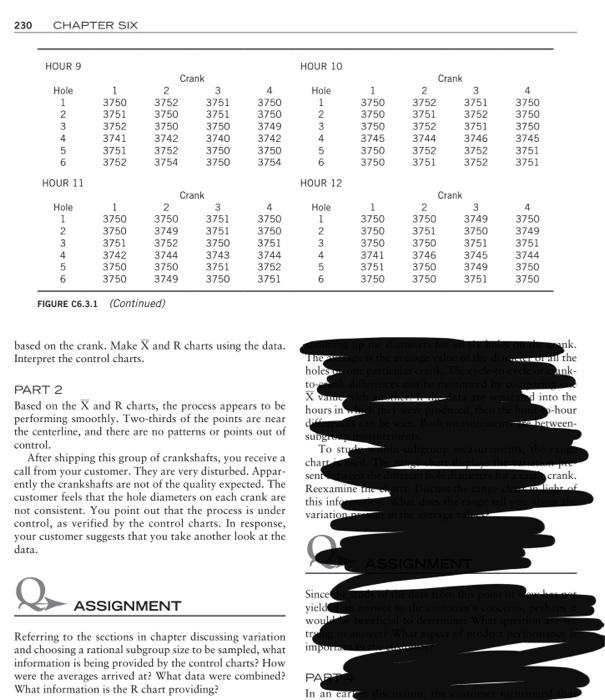

Sample-Size Considerations PART 1 WT Corporation manufactures crankshafts for 2-L auto- motive engines. To attach a crankshaft to a flywheel, six holes are drilled in the flange end of the crankshaft. These holes are to be drilled 0.3750 () inch in diameter. The holes are not threaded and go all the way through the flange. HOUR 1 Hole 1 2 3 4 5 6 CASE STUDY 6.3 X-bar Range HOUR 3 Hole 1 23456 HOUR 5 Hole 1 123456 HOUR 7 Hole 1 2 3 4 5 1 3751 3752 3747 3745 3752 3753 3750 8 1 3751 3748 3749 3745 3750 2 3 3752 3750 3751 3750 3752 3752 3745 3741 3751 3750 3750 3752 Crank 3750 7 3744 3751 3752 3749 2 3749 3752 3749 1 2 3751 3752 3754 3750 3752 3753 3745 3746 3751 3751 3750 3752 2 3749 Crank Crank 3749 11 3 3752 3751 3753 3744 3752 3750 3 3754 3751 3752 Crank 3747 3753 3753 4 3750 3752 FIGURE C6.3.1 Crankshaft Measurements 3749 3745 3752 3750 3750 7 4 3753 3753 3752 3743 3750 3753 4 3753 3752 3751 3746 1 3 4 3751 3750 3751 3752 3751 3754 3750 3752 3750 3753 3750 3754 3745 3742 3744 3750 3750 3750 3751 3749 3751 3750 3750 3754 3751 Variables Control Charts All six holes are drilled simultaneously. Every hour, the operator inspects four cranks resulting from four consecu- tive cycles of the drill press. All six holes on each of four crankshafts are measured and the values are recorded. The values are provided in Figure C6.3.1. b ASSIGNMENT Following the example set with the first two subgroups, use the data in Figure C6.3.1 to calculate X and R values HOUR 2 Hole 1 2 3 4 5 6 HOUR 4 Hole 1 2 3 4 5 6 HOUR 6 Hole 1 2 3 4 5 6 HOUR 8 Hole 1 2 3 3 10 10 4 5 6 1 3750 3749 3748 3745 3750 3751 3749 6 1 3751 3750 3752 3753 1 3752 3751 3753 3744 2 3753 3751 3749 3750 3741 3745 3755 3752 2 3751 3752 3748 3744 3754 3750 3750 10 1 3752 3751 3753 3744 3751 3750 Crank 3751 3750 3750 3751 Crank 2 3750 3750 3750 3745 3751 3750 Crank 3 3752 3754 3753 3745 3753 3752 3752 9 3 3752 3751 3751 3744 3751 3754 3 3751 3752 3753 3746 3751 3750 Crank 2 3 3751 3753 3752 3753 3746 3753 3750 3745 3752 3752 3753 3752 3751 3746 3750 3753 3751 7 4 3750 3751 3752 3745 3750 3753 4 3750 3750 3750 3744 3751 3750 4 3750 3750 3751 3744 229 3750 3750 230 CHAPTER SIX HOUR 9 Hole 1 2 3 4 5 6 HOUR 11 Hole 1 2 3 4 5 6 1 3750 3751 3752 3741 3751 3752 2 3752 3750 3750 3742 3752 3754 Crank FIGURE C6.3.1 (Continued) Crank 3 3751 3751 3750 1 2 3 3750 3750 3751 3750 3749 3751 3751 3752 3750 3742 3744 3743 3750 3750 3751 3749 3750 3740 3750 3750 4 3750 3750 3749 3742 ASSIGNMENT 3750 3754 4 3750 375 3751 3744 3752 3750 3751 based on the crank. Make X and R charts using the data. Interpret the control charts. PART 2 Based on the X and R charts, the process appears to be performing smoothly. Two-thirds of the points are near the centerline, and there are no patterns or points out of control. After shipping this group of crankshafts, you receive a call from your customer. They are very disturbed. Appar- ently the crankshafts are not of the quality expected. The customer feels that the hole diameters on each crank are not consistent. You point out that the process is under control, as verified by the control charts. In response, your customer suggests that you take another look at the data. Referring to the sections in chapter discussing variation and choosing a rational subgroup size to be sampled, what information is being provided by the control charts? How were the averages arrived at? What data were combined? What information is the R chart providing? HOUR 10 Hole 1 23456 HOUR 12 Hole 1 2 3 4 5 6 to X Vanue hours in dice subgr The holesom To stud char sent 1 3750 3750 3750 3745 3750 3750 Since yield woul tra import 3751 3750 Crank 2 3 3752 3751 3751 3752 3752 3751 3744 3746 3752 3751 Reexamine the this info variation in the 1 2 3 3750 3750 3749 3750 3751 3750 3750 3750 3751 3741 3746 3745 3750 3749 3750 3751 Crank 3752 3752 ASSIGNMENT PAP In an care discilkun, the costiline 4 3750 3750 3750 3745 3751 3751 4 3750 3749 3751 3744 3750 3750 ank. en the ank- d into the -hour on between- crank. light of

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock