Question: I only need letter c, please help. Case Study: Badger Meter The Badger Meter Company manufactures and distributes meters used to measure electric consumption. The

I only need letter c, please help.

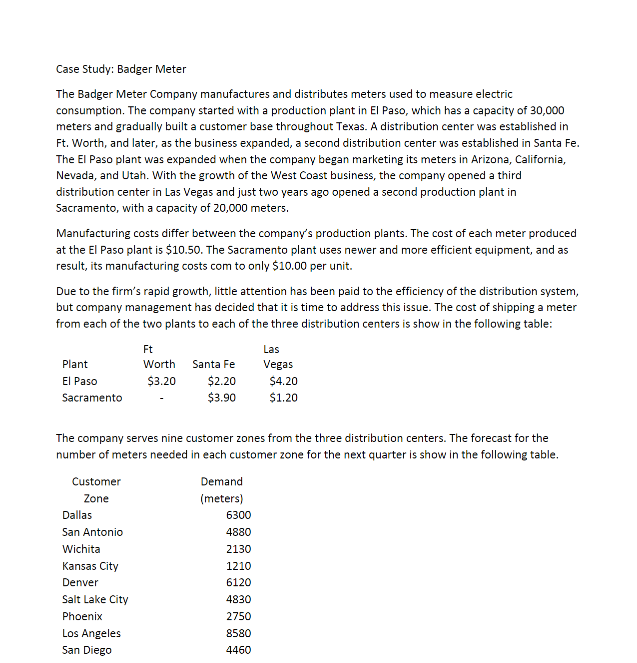

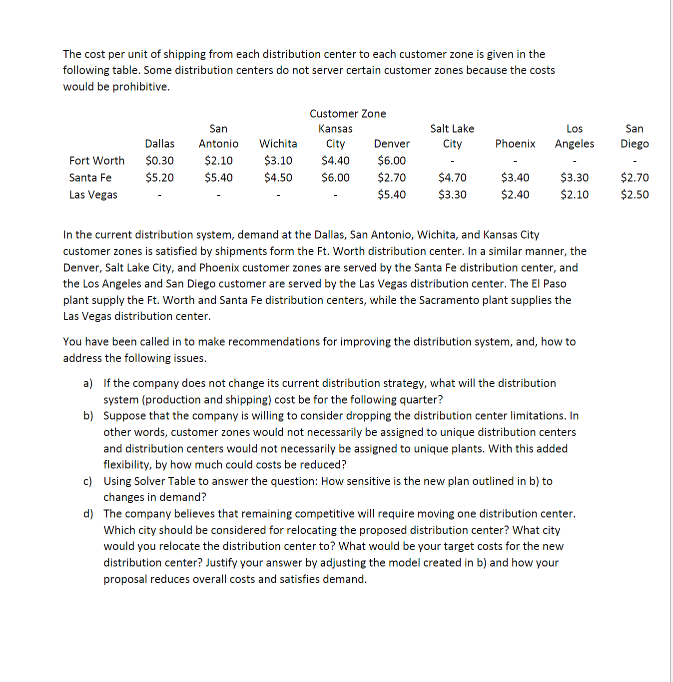

Case Study: Badger Meter The Badger Meter Company manufactures and distributes meters used to measure electric consumption. The company started with a production plant in El Paso, which has a capacity of 30,000 meters and gradually built a customer base throughout Texas. A distribution center was established in Ft. Worth, and later, as the business expanded, a second distribution center was established in Santa Fe. The El Paso plant was expanded when the company began marketing its meters in Arizona, California, Nevada, and Utah. With the growth of the West Coast business, the company opened a third distribution center in Las Vegas and just two years ago opened a second production plant in Sacramento, with a capacity of 20,000 meters. Manufacturing costs differ between the company's production plants. The cost of each meter produced at the El Paso plant is $10.50. The Sacramento plant uses newer and more efficient equipment, and as result, its manufacturing costs com to only $10.00 per unit. Due to the firm's rapid growth, little attention has been paid to the efficiency of the distribution system, but company management has decided that it is time to address this issue. The cost of shipping a meter from each of the two plants to each of the three distribution centers is show in the following table: The company serves nine customer zones from the three distribution centers. The forecast for the number of meters needed in each customer zone for the next quarter is show in the following table. The cost per unit of shipping from each distribution center to each customer zone is given in the following table. Some distribution centers do not server certain customer zones because the costs would be prohibitive. In the current distribution system, demand at the Dallas, San Antonio, Wichita, and Kansas City customer zones is satisfied by shipments form the Ft. Worth distribution center. In a similar manner, the Denver, Salt Lake City, and Phoenix customer zones are served by the Santa Fe distribution center, and the Los Angeles and San Diego customer are served by the Las Vegas distribution center. The El Paso plant supply the Ft. Worth and Santa Fe distribution centers, while the Sacramento plant supplies the Las Vegas distribution center. You have been called in to make recommendations for improving the distribution system, and, how to address the following issues. a) If the company does not change its current distribution strategy, what will the distribution system (production and shipping) cost be for the following quarter? b) Suppose that the company is willing to consider dropping the distribution center limitations. In other words, customer zones would not necessarily be assigned to unique distribution centers and distribution centers would not necessarily be assigned to unique plants. With this added flexibility, by how much could costs be reduced? c) Using Solver Table to answer the question: How sensitive is the new plan outlined in b) to changes in demand? d) The company believes that remaining competitive will require moving one distribution center. Which city should be considered for relocating the proposed distribution center? What city would you relocate the distribution center to? What would be your target costs for the new distribution center? Justify your answer by adjusting the model created in b) and how your proposal reduces overall costs and satisfies demand

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts