Question: Ideally the flash length should be T = 12 mm, but an acceptable range for this length is given by USL = 14 mm and

Ideally the flash length should be T = 12 mm, but an acceptable range for this length is given by USL = 14 mm and LSL = 10 mm.

To try and meet these requirements, the friction welding process is operating at a condition such that the process variables on average have values of 1.3mm, 38Hz, 75MPa and 1.3mm for amplitude, frequency, pressure and burn-off respectively. These process variables are therefore noise variables and they have been shown to follow normal distributions with standard deviations of 0.2mm, 3Hz, 9MPa and 0.1mm for the distributions of amplitude, frequency, pressure and burn-off respectively - not matter what the values are for these variables on average. (Note these are the conditions that generate the 30 flash lengths given to you in part B of the assignment).

From this starting point you must search for a better set of operating conditions by searching over the following range of conditions using a Genetic Algorithm:

Amplitude: 1-2mm

Frequency: 30-60Hz

Pressure: 70-90 MPa

Burn-off: 1-2 mm

Further, pressure and frequency must be integer values, whilst burn-off and amplitude can take on any value within the above ranges.

The objective of this search is to minimise the value for scrap costs over half a days production of welds (assuming the company operates at maximum capacity over a year). For this search, use a population size of 100 and run the genetic algorithm for exactly 1500 generations or trials. When generating scenarios within the population used the Monte Carlo technique with an initial seed of 555. Leave all other setting within the Genetic algorithm unchanged at their default values. For this optimisation, simulate the process for half a day assuming operating at maximum capacity

->What value for the mean frequency minimises the annual scrap cost assuming the company operates at maximum capacity?

->What value for the mean weld amplitude minimises the annual scrap cost assuming the company operates at maximum capacity?

->What value for the mean forge pressure minimizes the annual scrap cost assuming the company operates at maximum capacity?

->What value for the mean burn - off minimizes the annual scrap cost assuming the company operates at maximum capacity?

->What is the minimised value for the annual scrap cost (to the nearest whole number)?

->Which of the following statement(s) is a false description of your optimised process?

.When control engineers manage to minimise the standard deviations for all the process variables, the scrap cost will be minimised.

.When control engineers manage to set the standard deviations for all the process variables at zero, the scrap cost will be minimised.

.When control engineers manage to set all the process variables at the values you supplied in questions 1 to 4 above (assuming you supplied the correct answers), the scrap cost will be minimised.

.When control engineers manage to set all the process variables on average at the values you supplied in questions 1 to 4 above (assuming you supplied the correct answers), the scrap cost will be minimised.

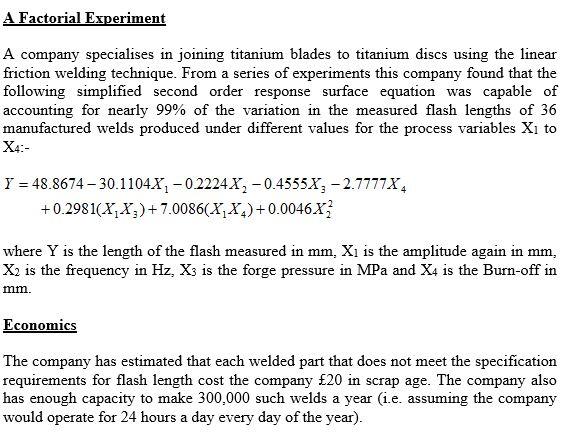

A Factorial Experiment A company specialises in joining titanium blades to titanium discs using the linear friction welding technique. From a series of experiments this company found that the following simplified second order response surface equation was capable of accounting for nearly 99% of the variation in the measured flash lengths of 36 manufactured welds produced under different values for the process variables X to X4:- Y = 48.8674-30.1104x; -02224x2 -0.4555X; -2.7777X. +0.2981(x,x)+7.0086(XX) +0.0046X3 where Y is the length of the flash measured in mm. Xi is the amplitude again in mm, X2 is the frequency in Hz, X3 is the forge pressure in MPa and X4 is the Burn-off in mm. Economics The company has estimated that each welded part that does not meet the specification requirements for flash length cost the company 20 in scrap age. The company also has enough capacity to make 300,000 such welds a year (i.e. assuming the company would operate for 24 hours a day every day of the year)Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts