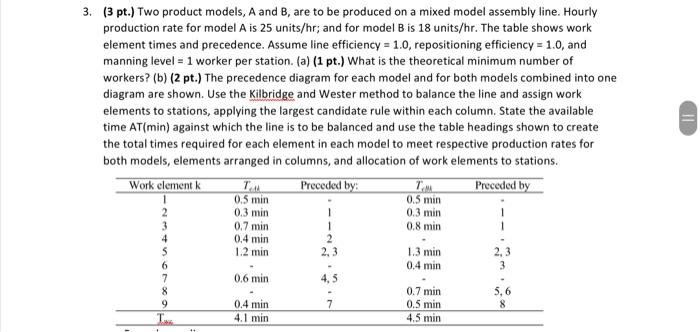

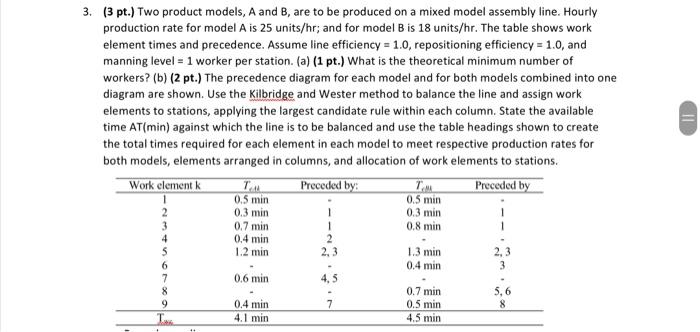

Question: Il 3. (3 pt.) Two product models, A and B, are to be produced on a mixed model assembly line. Hourly production rate for model

Il 3. (3 pt.) Two product models, A and B, are to be produced on a mixed model assembly line. Hourly production rate for model A is 25 units/hr; and for model B is 18 units/hr. The table shows work element times and precedence. Assume line efficiency = 1.0, repositioning efficiency = 1.0, and manning level = 1 worker per station. (a) (1 pt.) What is the theoretical minimum number of workers? (b) (2 pt.) The precedence diagram for each model and for both models combined into one diagram are shown. Use the Kilbridge and Wester method to balance the line and assign work elements to stations, applying the largest candidate rule within each column. State the available time AT(min) against which the line is to be balanced and use the table headings shown to create the total times required for each element in each model to meet respective production rates for both models, elements arranged in columns, and allocation of work elements to stations. Work clement k T. Preceded by: Preceded by 0.5 min 0.5 min 0.3 min 1 0.3 min 3 0.7 min 0.8 min 0.4 min 1.2 min 2,3 1.3 min 2,3 0.4 min 3 0.6 min 4,5 0.7 min 5,6 0.4 min 0.5 min 4.1 min 4.5 min 1 2 8 9 7 8 Il 3. (3 pt.) Two product models, A and B, are to be produced on a mixed model assembly line. Hourly production rate for model A is 25 units/hr; and for model B is 18 units/hr. The table shows work element times and precedence. Assume line efficiency = 1.0, repositioning efficiency = 1.0, and manning level = 1 worker per station. (a) (1 pt.) What is the theoretical minimum number of workers? (b) (2 pt.) The precedence diagram for each model and for both models combined into one diagram are shown. Use the Kilbridge and Wester method to balance the line and assign work elements to stations, applying the largest candidate rule within each column. State the available time AT(min) against which the line is to be balanced and use the table headings shown to create the total times required for each element in each model to meet respective production rates for both models, elements arranged in columns, and allocation of work elements to stations. Work clement k T. Preceded by: Preceded by 0.5 min 0.5 min 0.3 min 1 0.3 min 3 0.7 min 0.8 min 0.4 min 1.2 min 2,3 1.3 min 2,3 0.4 min 3 0.6 min 4,5 0.7 min 5,6 0.4 min 0.5 min 4.1 min 4.5 min 1 2 8 9 7 8