Question: In EDM, the cutting tool is actually: a . contacting the work b . an electrode c . non - consumable d . hardened to

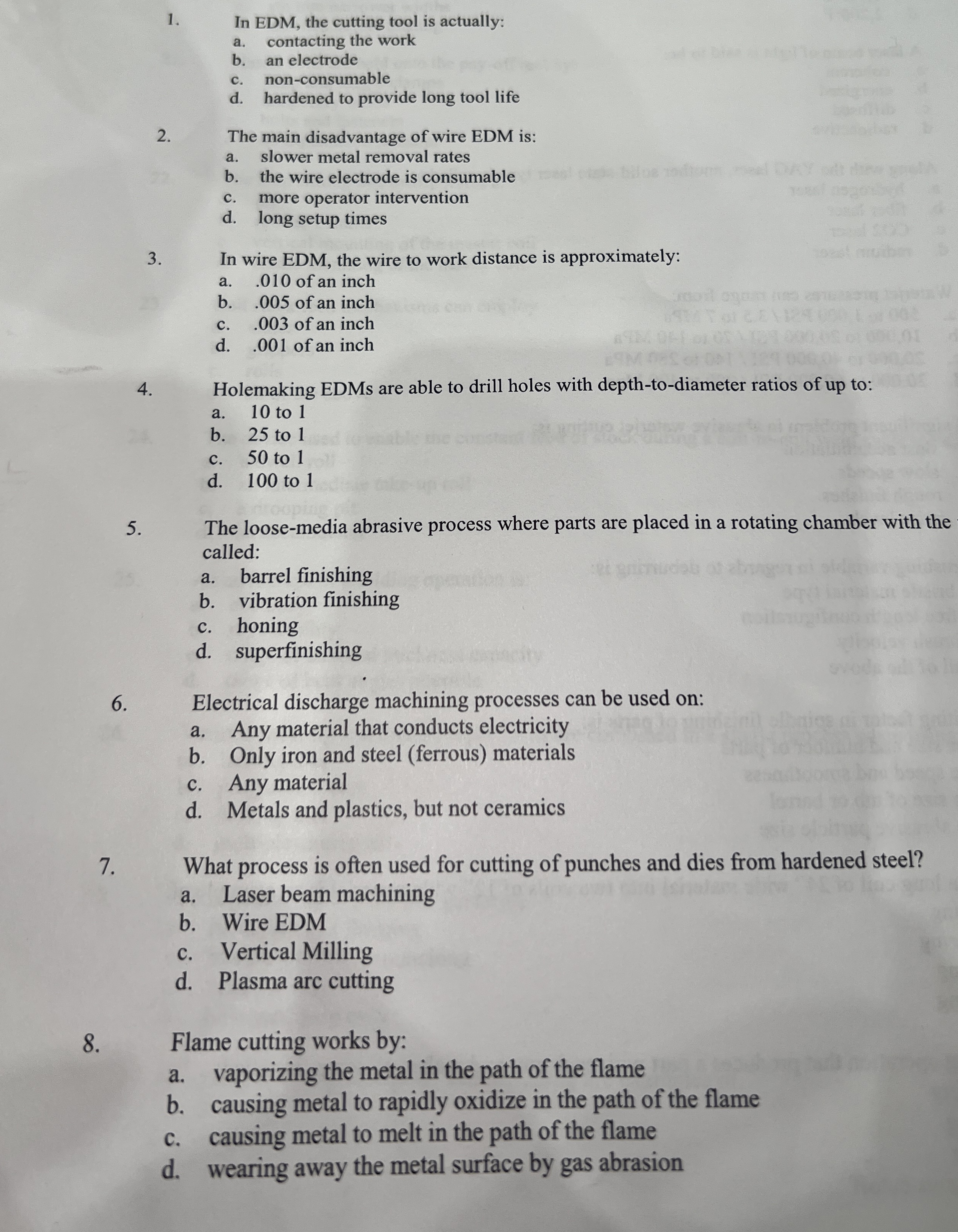

In EDM, the cutting tool is actually:

a contacting the work

b an electrode

c nonconsumable

d hardened to provide long tool life

The main disadvantage of wire EDM is:

a slower metal removal rates

b the wire electrode is consumable

c more operator intervention

d long setup times

In wire EDM, the wire to work distance is approximately:

a of an inch

b of an inch

c of an inch

d of an inch

Holemaking EDMs are able to drill holes with depthtodiameter ratios of up to:

a to

b to

c to

d to

The loosemedia abrasive process where parts are placed in a rotating chamber with the called:

a barrel finishing

b vibration finishing

c honing

d superfinishing

Electrical discharge machining processes can be used on:

a Any material that conducts electricity

b Only iron and steel ferrous materials

c Any material

d Metals and plastics, but not ceramics

What process is often used for cutting of punches and dies from hardened steel?

a Laser beam machining

b Wire EDM

c Vertical Milling

d Plasma arc cutting

Flame cutting works by:

a vaporizing the metal in the path of the flame

b causing metal to rapidly oxidize in the path of the flame

c causing metal to melt in the path of the flame

d wearing away the metal surface by gas abrasion

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock