Question: In the hand simulation of the simple processing system, suppose the drill press is taken down for burn-in maintenance at time 4 minutes, and it

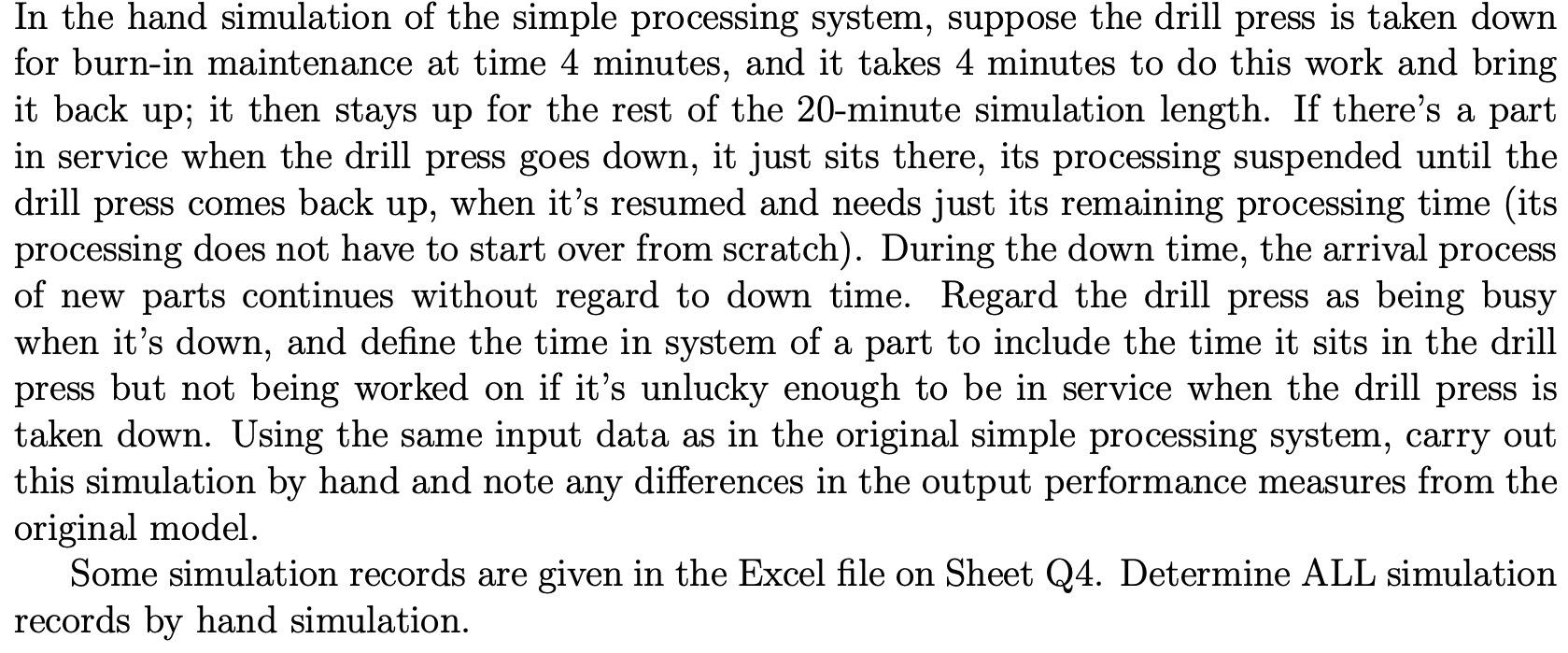

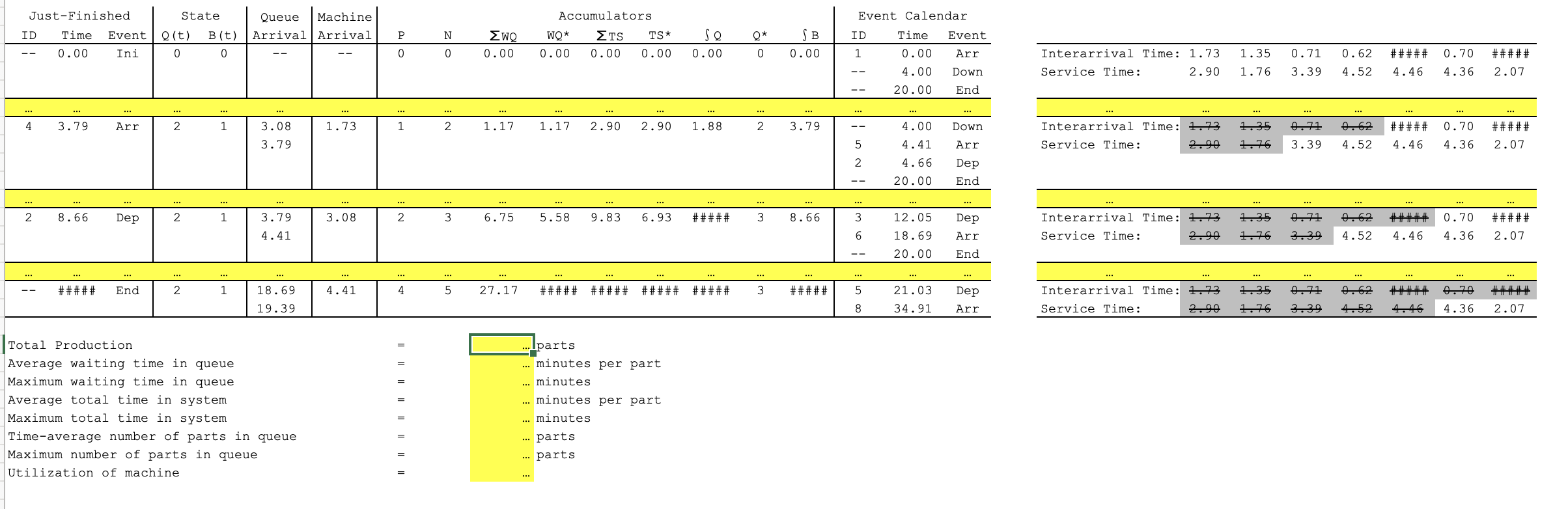

In the hand simulation of the simple processing system, suppose the drill press is taken down for burn-in maintenance at time 4 minutes, and it takes 4 minutes to do this work and bring it back up; it then stays up for the rest of the 20-minute simulation length. If there's a part in service when the drill press goes down, it just sits there, its processing suspended until the drill press comes back up, when it's resumed and needs just its remaining processing time (its processing does not have to start over from scratch). During the down time, the arrival process of new parts continues without regard to down time. Regard the drill press as being busy when it's down, and define the time in system of a part to include the time it sits in the drill press but not being worked on if it's unlucky enough to be in service when the drill press is taken down. Using the same input data as in the original simple processing system, carry out this simulation by hand and note any differences in the output performance measures from the original model. Some simulation records are given in the Excel file on Sheet Q4. Determine ALL simulation records by hand simulation

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts