Question: kindly assit with this question on workshop safety after reading the case study provided above we are supposed to answer questions 1 to 4 it's

kindly assit with this question on workshop safety

after reading the case study provided above we are supposed to answer questions 1 to 4 it's based on workshop safety

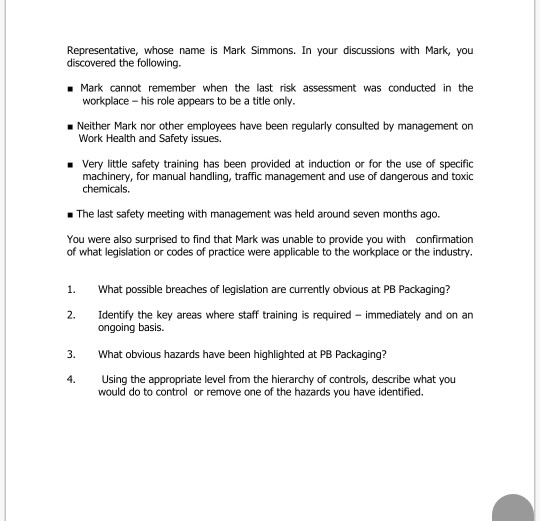

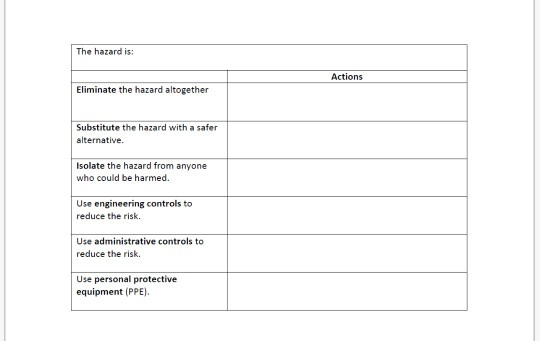

WORKSHOP ACTIVITY CASE STUDY: PB PACKAGING PTY LTD You have accepted an interstate transfer to take on the role of Operations Supervisor at PB Packaging Pty Ltd. The organisation you work for manufacturers cans from rolled steel and tubing. Coatings, labels and other finishing and packaging processes are applied to the products before they are despatched to customers. 115 people work at your new site. 80 work in the manufacturing area, 20 in management and administration, and 15 work in stores and despatch. A key responsibility of your new role is to review all site WHS strategies, policies and processes to improve overall safety standards. Your manager has set you very clear KPIs relating to WHS training, hazard and incident reporting, risk assessments, safe work procedures, lost time injuries and Workers Compensation claims. There are many types of specialist machinery used at the site. These include cupping, seaming, flanging, wrapping and packing machines, presses, dyes and stamps. All machines require trained, experienced employees who have developed the specific skill sets needed to operate them effectively and safely. HR records show that there are 45 people employed as machine operators at the site. Additional training is also required when machinery is changed or reengineered. In the last 12 months several pieces of new equipment have been purchased so that production levels could be increased to meet customer demand. Operators that you have spoken to have stated that there has been an increase in workplace injuries since the new machines began operating. Team leaders have indicated that they were unhappy they were not consulted prior to the new machinery being purchased. Little or no training was provided to employees on how to safely operate the new equipment. The operating manuals for two of the new machines were only provided in German language. The HR department has told you that there has been an increase in absenteeism since the new machinery was implemented. Additionally, you have been informed that several employees have indicated they are concerned about the safe operation of some of the old machinery, Workers who are operating these have been reporting minor injuries to their team leaders on a regular basis. Some existing safety guards are faulty and the emergency stop buttons on two of the machines are not working. Further investigations you have undertaken have shown that there is no site hazard register or formal incident reporting system in place. From what you can see there seems to be minimal risk control measures and practices being applied or implemented in any part of the workplace. Evacuation diagrams are out of date or not visible. Apparently there is no site induction process in place for contractors and suppliers. You were also surprised to find out that there was no active safety committee in place either. You have however, been able to identify an employee Workplace Safety Representative, whose name is Mark Simmons. In your discussions with Mark, you discovered the following. Mark cannot remember when the last risk assessment was conducted in the workplace - his role appears to be a title only. . Neither Mark nor other employees have been regularly consulted by management on Work Health and Safety issues. Very little safety training has been provided at induction or for the use of specific machinery, for manual handling, traffic management and use of dangerous and toxic chemicals. The last safety meeting with management was held around seven months ago You were also surprised to find that Mark was unable to provide you with confirmation of what legislation or codes of practice were applicable to the workplace or the industry. 1. 2. What possible breaches of legislation are currently obvious at PB Packaging? Identify the key areas where staff training is required - immediately and on an ongoing basis. What obvious hazards have been highlighted at PB Packaging? Using the appropriate level from the hierarchy of controls, describe what you would do to control or remove one of the hazards you have identified. 3. 4. The hazard is: Actions Eliminate the hazard altogether Substitute the hazard with a safer alternative. Isolate the hazard from anyone who could be harmed. Use engineering controls to reduce the risk. Use administrative controls to reduce the risk. Use personal protective equipment (PPE)Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock