Question: Lean Operations at Alaska Airlines Video Case Applying to identify aircraft ground equipment and its location on the tarmac Improving preparation for and synchronization of

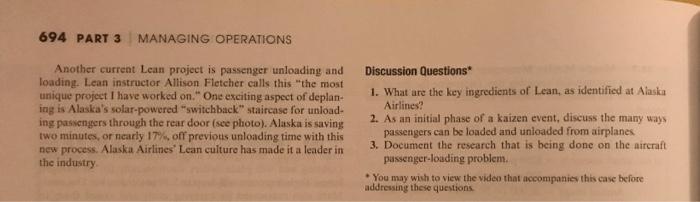

Lean Operations at Alaska Airlines Video Case Applying to identify aircraft ground equipment and its location on the tarmac Improving preparation for and synchronization of the arrival and departure sequences, time to open the front door after amval has been reduced from 4.5 to 1 min. Redefining the disconnect procedure for tow bars used to "push hack aircraft at departure time; planes now depart 2 3 minutes faster Revising the deicing process, meaning less time for the plane to be on the tarmac Improving pilot staffing, making Alaska's pilot productivity the highest in the industry. Every 19. improvement in pro- ductivity leads to a 35 million savings on a recurring basis Alaska Airlines has achieved a productivity improvement over the last five years . Als Airlines operates in a land of rugged beauty. crystal clear Miss spectacular glaciers majestic mountains, and bright blue But equally awesome is its operating performance Alaska Aines consistently provides the industry's number one overall ning and best on-time performance. A key ingredient of this callest performance is Alaska Airlines' Lean initiative with an aggressive implementation of Lean, Ben Minicucci, Executhe VP for Operations, is finding ever-increasing levels of performance. He pushes this initiative throughout the company with: (1) a focus on continuous improvement, (2) metrics that mature performance against targets, and (3) making perfor mance relevant to Alaska Airlines' empowered employees With leadership training that includes a strong focus on participative management, Minicucci has created a seven-person Luan Department. The department provides extensive train ingin Lean via one week courses, participative workshops, and Torock classes that train employees to become a Six Sigma Groen Belt Some employees even pursue the next step, Black Belt rition A huge part of any airline's operations is fuel cost, but capital utilization and much of the remaining cost is dependent upon pround equipment and crews that handle aircraft turnaround and maintenance, in-flight services, and customer service As John Ladner, Director of Scattle Airport Operations, has herved, "Lean eliminates waste, exposes non-standard work, and is forcing a focus on variations in documented best practices and work time Lean is now part of the Alaska Airlines corporate culture, with ongoing projects. Kaizen events (called "Accelerated laprovement Workshops" at Alaska Airlines, Gemba Walks called We walks by Alaska Airlines, and are now a part of every de conversation at Alaska Airlines. Lean projects have included: 694 PART 3 MANAGING OPERATIONS Another current Lean project is passenger unloading and loading. Lean instructor Allison Fletcher calls this the most unique project I have worked on." One exciting aspect of deplan ing is Alaska's solar-powered "switchback" staircase for unload- ing passengers through the rear door (see photo). Alasku is saving two minutes, or nearly 17% off previous unloading time with this new process. Alaska Airlines Lean culture has made it a leader in the industry Discussion Questions 1. What are the key ingredients of Lean, as identified at Alaska Airlines? 2. As an initial phase of a kaizen event, discuss the many ways passengers can be loaded and unloaded from airplanes 3. Document the research that is being done on the aircraft passenger-loading problem. You may wish to view the video that accompanies this case before addressing these questions