Question: Logistics Management Homework #3 Problem 1. (Chapter 4: Logistics/Supply Chain Customer Service) A food company is attempting to set the customer service level (in-stock probability

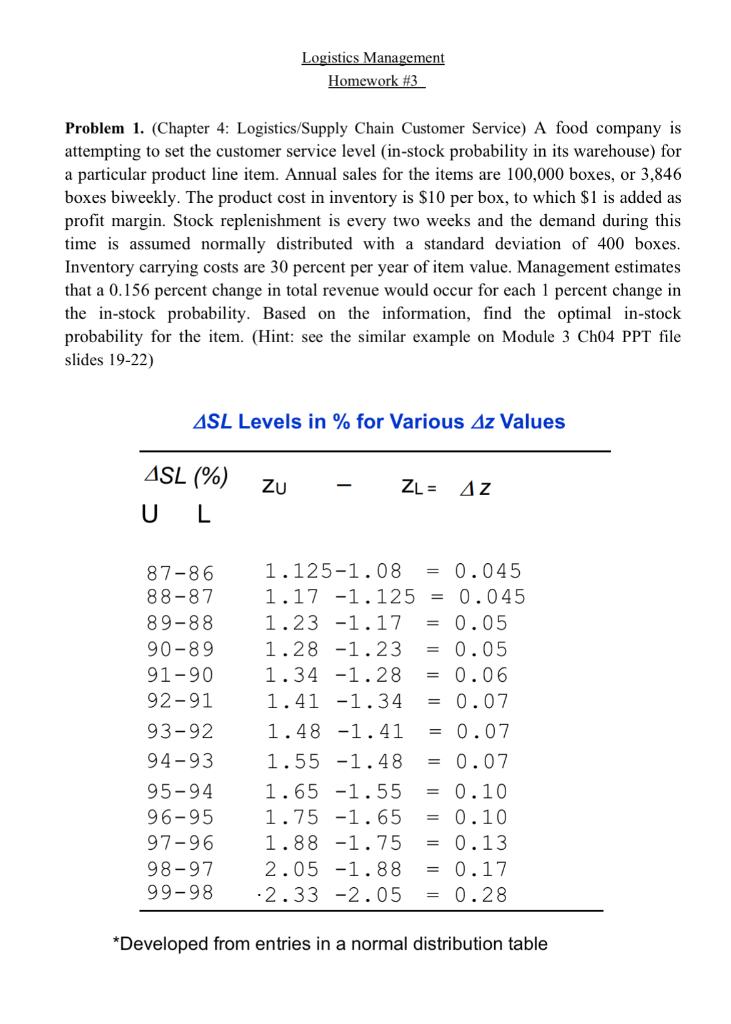

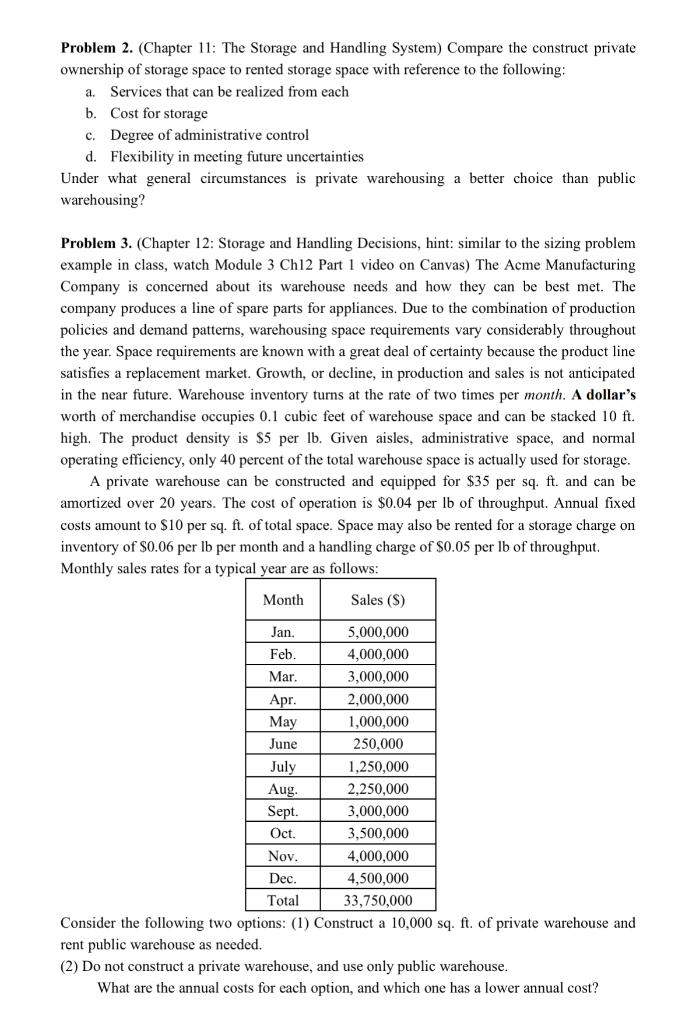

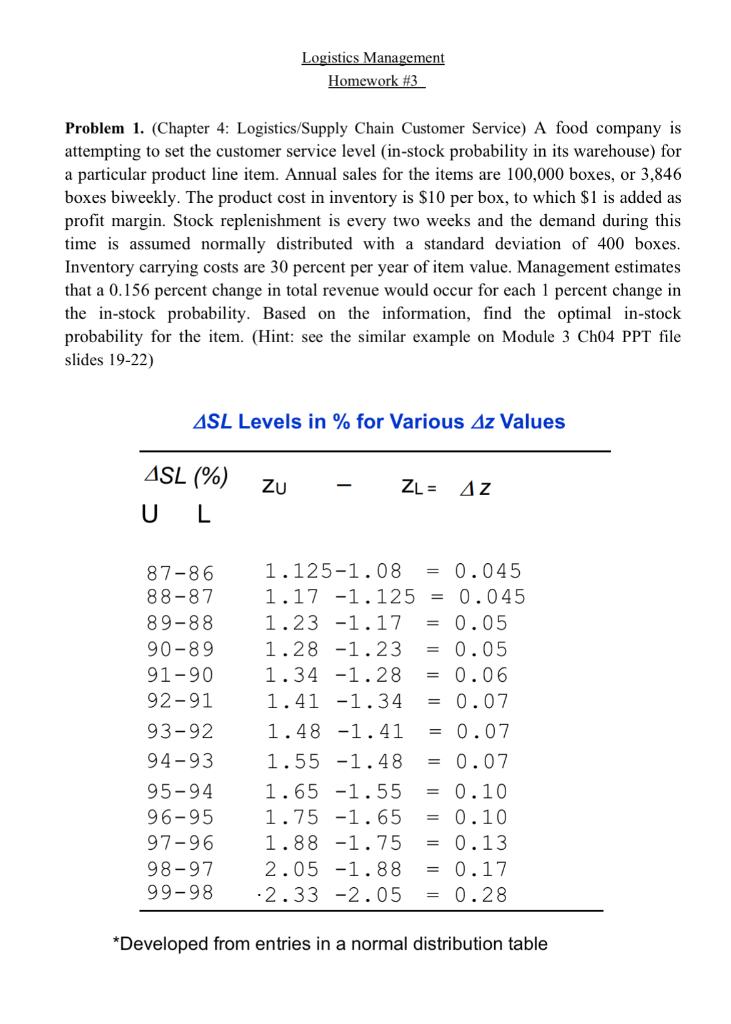

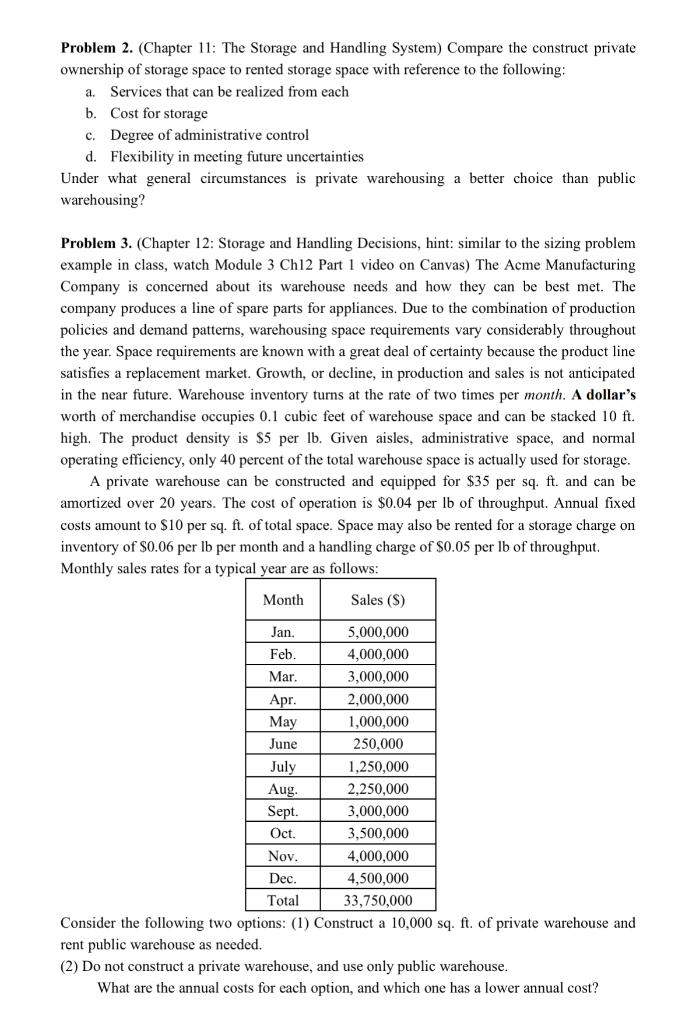

Logistics Management Homework #3 Problem 1. (Chapter 4: Logistics/Supply Chain Customer Service) A food company is attempting to set the customer service level (in-stock probability in its warehouse) for a particular product line item. Annual sales for the items are 100,000 boxes, or 3,846 boxes biweekly. The product cost in inventory is $10 per box, to which $1 is added as profit margin. Stock replenishment is every two weeks and the demand during this time is assumed normally distributed with a standard deviation of 400 boxes. Inventory carrying costs are 30 percent per year of item value. Management estimates that a 0.156 percent change in total revenue would occur for each 1 percent change in the in-stock probability. Based on the information, find the optimal in-stock probability for the item. (Hint: see the similar example on Module 3 Ch04 PPT file slides 19-22) ASL Levels in % for Various Az Values ASL (%) U L ZU ZL = AZ = 87-86 88-87 89-88 90-89 91-90 92-91 93-92 94-93 95-94 96-95 97-96 98-97 99-98 1.125-1.08 0.045 1.17 -1.125 = 0.045 1.23 -1.17 0.05 1.28 -1.23 0.05 1.34 -1.28 = 0.06 1.41 -1.34 0.07 1.48 -1.41 = 0.07 1.55 -1.48 0.07 1.65 -1.55 = 0.10 1.75 -1.65 = 0.10 1.88 -1.75 = 0.13 2.05 -1.88 = 0.17 -2.33 -2.05 = 0.28 *Developed from entries in a normal distribution table Problem 2. (Chapter 11: The Storage and Handling System) Compare the construct private ownership of storage space to rented storage space with reference to the following: a. Services that can be realized from each b. Cost for storage C. Degree of administrative control d. Flexibility in meeting future uncertainties Under what general circumstances is private warehousing a better choice than public warehousing? Problem 3. (Chapter 12: Storage and Handling Decisions, hint: similar to the sizing problem example in class, watch Module 3 Ch12 Part 1 video on Canvas) The Acme Manufacturing Company is concerned about its warehouse needs and how they can be best met. The company produces a line of spare parts for appliances. Due to the combination of production policies and demand patterns, warehousing space requirements vary considerably throughout the year. Space requirements are known with a great deal of certainty because the product line satisfies a replacement market. Growth, or decline, in production and sales is not anticipated in the near future. Warehouse inventory turns at the rate of two times per month. A dollar's worth of merchandise occupies 0.1 cubic feet of warehouse space and can be stacked 10 ft. high. The product density is $5 per lb. Given aisles, administrative space, and normal operating efficiency, only 40 percent of the total warehouse space is actually used for storage. A private warehouse can be constructed and equipped for $35 per sq. ft. and can be amortized over 20 years. The cost of operation is $0.04 per lb of throughput. Annual fixed costs amount to $10 per sq. ft. of total space. Space may also be rented for a storage charge on inventory of $0.06 per lb per month and a handling charge of $0.05 per lb of throughput. Monthly sales rates for a typical year are as follows: Month Sales (S) Jan. 5,000,000 Feb. 4,000,000 Mar. 3,000,000 Apr. 2,000,000 May 1,000,000 June 250,000 July 1,250,000 Aug. 2,250,000 Sept. 3,000,000 Oct. 3,500,000 Nov 4,000,000 Dec. 4,500,000 Total 33,750,000 Consider the following two options: (1) Construct a 10,000 sq. ft. of private warehouse and rent public warehouse as needed. (2) Do not construct a private warehouse, and use only public warehouse. What are the annual costs for each option, and which one has a lower annual cost