Question: m3n (a) How long it will take to perform cach activity is estimated (h) In order to locate the critical path, calculation is performed (the

m3n

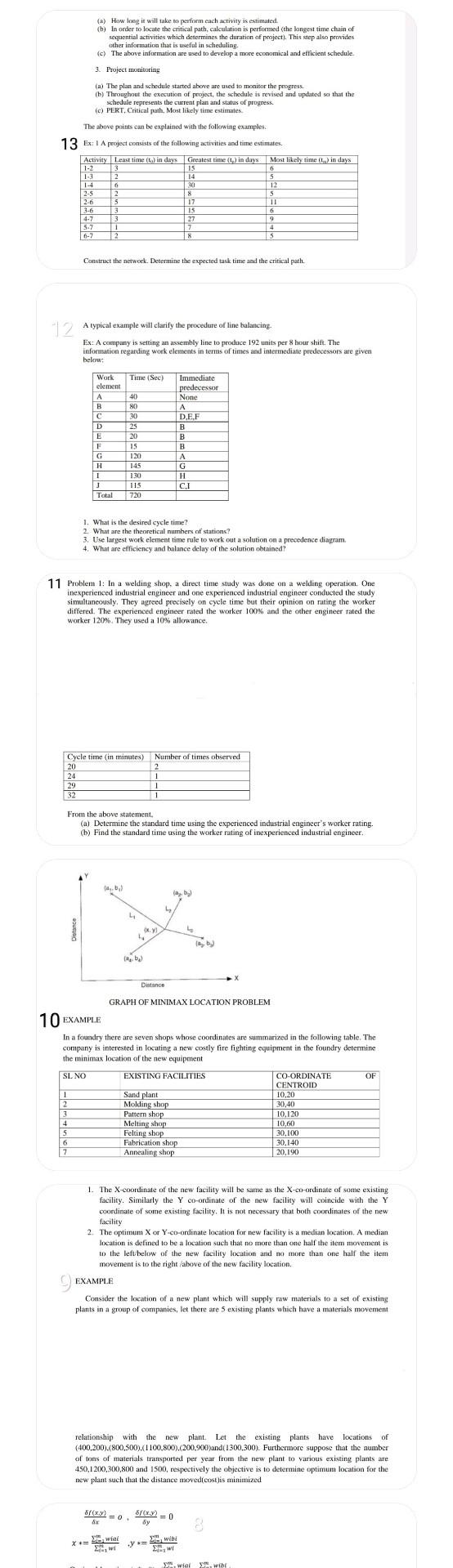

(a) How long it will take to perform cach activity is estimated (h) In order to locate the critical path, calculation is performed (the longest time chain of sequential activities which determines the duration of project). This step also provides other information that is useful in scheduling. (c) The above information are used to develop a more economical and efficient schedule. 3. Project monitoring (a) The plan and schedule started above are used in monitor the progress (b) Throughout the execution of project, the schedule is revised and updated so that the schedule represents the current plan and status of progress. (c) PERT, Critical path, Most likely time estimates The above points can be explained with the following examples 13 Ex 1 A project consists of the following activities and time estimates. Activity Least time (t) in days Greatest time() in days Most likely time (t) in days 1-2 3 15 16 1-3 2 14 5 1-4 6 30 12 2-5 2 18 5 26 5 17 11 3-6 3 15 6 4-7 3 27 9 5.7 1 7 4 6-7 2 18 15 Construct the network. Determine the expected task time and the critical path. 12 A typical example will clarify the procedure of line buluneing. Ex: A company is setting an assembly line to produce 192 units per 8 hour shift. The information regarding work elements in terms of times and intermediate predecessors are given below: Time (Sec) Work clement A B D E F G H 1 J Total 40) 8) 30) 25 20 15 120 145 130 115 720 Immediate predecessor None A DEF . B B A G H CI 1. What is the desired cycle time? 2. What are the theoretical numbers of stations? 3. Use largest work element time rule to work out a solution on a precedence diagram 4. What are efficiency and balance delay of the solution obtained? 11 Problem 1: In a welding shop, a direct time study was done on a welding operation. One inexperienced industrial engineer and one experienced industrial engineer conducted the study simultaneously. They agreed precisely on cycle time but their opinion on rating the worker differed. The experienced engineer rated the worker 100% and the other engineer rated the worker 120%. They used a 10% allowance. Cycle time in minutes) 20 24 29 32 Number of times ohserved 2 1 1 1 From the above statement (a) Determine the standard time using the experienced industrial engineer's worker rating. (h) Find the standard time using the worker rating of inexperienced industrial engineer b) aby L . YI 4 Distance GRAPH OF MINIMAX LOCATION PROBLEM 10 EXAMPLE In a foundry there are seven shops whose coordinates are summarized in the following table. The company is interested in lexcuting a new costly fire fighting equipment in the foundry determine the minimax location of the new equipment SL NO EXISTING FACILITIES CO-ORDINATE OF CENTROID 1 Sand plant 10.20 Molding shop 30,40 Pattern shop 10,120 Melting shop 10,60 5 Felting shop 30,100 Fabrication shop 30.140 7 Annealing shop 20,190 2 3 4 0 1. The X-coordinate of the new facility will be same as the X-co-ordinate of some existing facility. Similarly the Y co-ordinate of the new facility will coincide with the Y Coordinate of some existing facility. It is not necessary that both coordinates of the new facility 2. The optimum Xor Y-co-ordinate location for new facility is a median location. A median location is defined to be a location such that no more than one half the item movement is to the left below of the new facility location and no more than one half the item movement is to the right abone of the new facility location EXAMPLE Consider the location of a new plant which will supply raw materials to a set of existing plants in a group of companies, let there are 5 existing plants which have a materials movement relationship with the new plant. Let the existing plants have locations of (400,200).(800,500).(1100,800).(200,600and (1300,300). Furthermore suppose that the number of tons of materials transported per year from the new plant to various existing plants are 450,1200,300,800 and 1500, respectively the objective is to determine optimum location for the new plant such that the distance movedi costis minimized 87() = 0 86x) =o. &x By X, Wiel y* 2W wi , w wiel wibStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock