Question: Managing Quality: Westover Electric Case Study Westover Dectrical Components, le is a small-stasie Based manufacturer of wire windings used in electric motors Ralph Stanley, VP

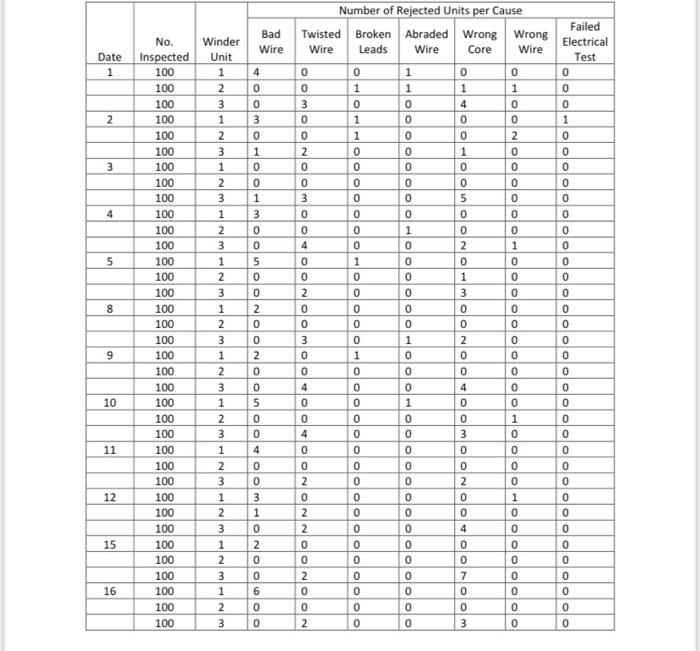

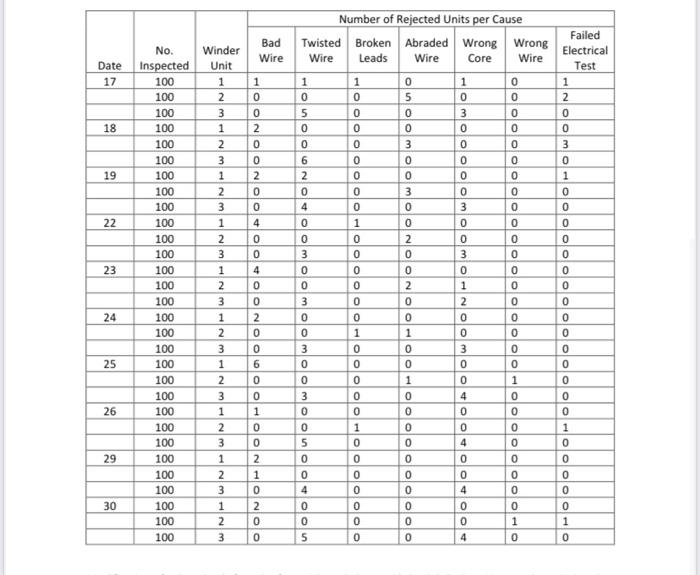

Managing Quality: Westover Electric Case Study Westover Dectrical Components, le is a small-stasie Based manufacturer of wire windings used in electric motors Ralph Stanley, VP operation has been an increasing problem with rejected product found during the manufacturing operation *I'm not sure where to begin, admitted Ralph at the weekly meeting with his boss. "Rejects in the Winding Department have been killing us the past two months Nobody in operations has an idea why. Thave just brought in a consultant, Arthel Watson, to take a look at the situation and make recommendations about how we can find out what is going on. I didn't ask Arthel to make technical recommendations - just see if he can points in the direction of our problem Watson's first stop later that day was the production for discussions with the production supervisors in the Winding Department indicated that they had no real grasp of what the problem was or what to do to correct it. A tour of the winding operation indicated that there were three machines that wound wire onto plastic cores to produce the primary and secondary electric motor windings. After Inspection by quality control these winding the wee to the Packaging Department Packaging personnel, Watson found, inspect their own work and make corrections on the spot Raapparent to Watson that the problem lies in that too many windingswed to be defective and require reworking before they can be packaged, rather than in the Packaging Dept Watson's next stop was the Quality Control Department where he obtained the records for the past month's Winding Department rejects (see table below ASSIGNMENT DIRECTIONS AND QUESTIONS: 1. Prepare Aethel Watson's recommendation, with justification, on one page Write it up as a memo/letter - be concise-one page of text with your recommendation and information backing up your conclusion 2. What charts, graphs, computer printouts, and so forth be included in the report to support your recommendation? You don't have to prepare all of the charts, grah, et just provide a description of what you would include as added to your letter 3. Prepare the detail necessary to supplemet wate's recommendation and justification so that Ralph Stanley will understand how Watson arrived at his recommendations and be able to present them to his management so they can correct the issue. ENVM 540 Fall 2020 Clarification: . I do want you to prepare some kind of condensed data presentation . One table and one crashtest-whatever you think will do the best job of conveying your findings quickly to management Include it as an addendum to your mem - t does not count toward your one page of material . Be aware that you may have to manipulate the data normalise, erar, etc.) to fully capture what is going on and before you put in a table chart, etc. Note: Assume each defective unit was rejected because of one single defect. Bad Wire a Date 1 4 lo 0 3 Nu ololo 2 1 0 Old 3 nN ololo mlolololololo ON 1 3 4 WN OC in 5 Holo 00 No. Inspected 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 8 Number of Rejected Units per Cause Twisted Broken Abraded Failed Wrong Wrong Electrical Wire Leads Wire Core Wire Test 0 1 0 0 1 1 1 1 0 0 0 4 0 0 1 0 0 0 1 1 0 0 2 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 5 0 0 0 0 0 0 0 0 1 0 0 0 0 2 1 0 1 0 0 0 0 0 0 1 0 0 0 3 0 0 0 0 0 0 0 0 0 0 0 0 0 1 2 0 0 1 0 0 0 0 0 0 0 0 0 4 0 0 1 0 0 0 1 0 0 3 0 0 0 0 0 0 0 2 0 0 1 0 0 0 0 4 0 0 0 0 0 0 0 0 7 0 0 0 0 Winder Unit 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 2 0 0 2 OOMOONOOMOOOONOOMOOOOOONONNOONOON 9 0 0 10 11 Tool OONOOWOO WN OO 12 3 ooOOONO WOO DOS NH OOO 15 2 16 nmnm wlolololo OOOOO olololo 0 OO 3 0 3 Bad Wire Number of Rejected Units per Cause Twisted Broken Abraded Wrong Wrong Wire Leads Wire Core Wire Date 17 1 0 0 0 0 0 0 0 18 0 0 0 0 0 0 19 1 0 0 2 0 0 2 0 0 4 0 0 4 0 0 2 0 1 0 5 0 0 6 2 0 4 0 0 3 0 0 3 0 0 No. Inspected 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 0 0 1 0 0 0 0 22 Failed Electrical Test 1 2 0 0 3 0 1 0 0 0 0 0 0 0 0 Winder Unit 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 0 5 0 0 3 0 0 3 0 0 2 0 0 2 0 0 1 0 0 0 0 0 0 0 23 1 0 3 0 0 0 0 0 3 0 0 3 0 1 2 0 0 3 0 0 4 0 0 4 0 0 4 0 0 0 24 0 0 0 0 0 0 0 0 25 0 1 0 0 0 0 0 0 6 0 0 1 3 0 0 3 0 0 0 1 0 0 1 0 0 0 0 0 26 0 5 0 1 0 0 0 0 0 2 1 0 0 0 1 0 29 0 0 0 0 0 0 0 0 0 30 HONOo 0 0 0 1 2 Oolon 0 0 0 0 0 OS 0 1 0 4 0 0