Question: MEM553 Problem Based Learning/ Complex Eingineering Problem GROUP ASSIGNMENT Commence Date: 4 rd Jan 2023 Dateline: 27ih Jan 2023 (Before 5 pm) Course Outcomes This

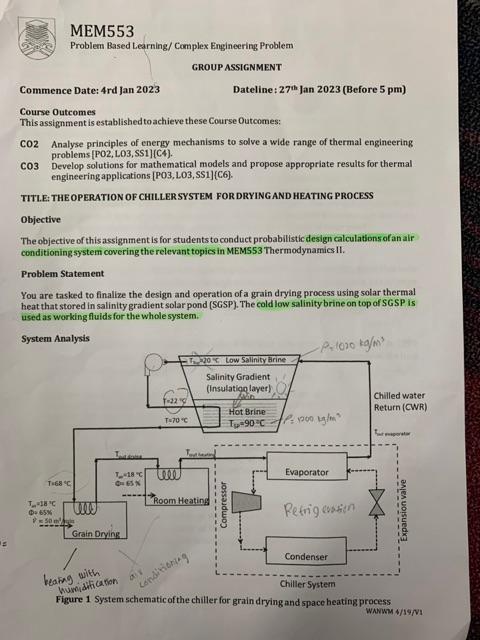

MEM553 Problem Based Learning/ Complex Eingineering Problem GROUP ASSIGNMENT Commence Date: 4 rd Jan 2023 Dateline: 27ih Jan 2023 (Before 5 pm) Course Outcomes This assignment is established to achieve these Course Outcomes: CO2 Analyse principles of energy mechanisms to solve a wide range of thermal engineering problems [PO2, LO3, SS1][C4]. CO3 Develop solutions for mathematical models and propose appropriate results for thermal engineering applications [P03, L03, SS1] {C6}. TITI.E: THE OPERATION OF CHIL.LER SYSTEM FOR DRYING AND HEATING PROCESS Objective The objective of this assignment is for students to conduct probabilistic design calculations of an alr conditioningsystem covering the relevant topics in MEMS53 Thermodynamics II. Problem Statement You are tasked to finalize the design and operation of a grain drying process using solar thermal heat that stored in salinity gradient solar pond (SGSP). The cold low salinity brine on top of SGSP is used as working fluids for the whole system. 7. If the surface temperature of the pipe carrying the chilled water return (CWR) is assumed steady along the pipe length, plot the heat transfer rate profile at the outer surface of the CWR pipe under surrounding conditions of natural convection current effect and wind effect of 2ms1,4ms1 and 6ms1 velocities. The effectlve CWR pipe length is 20 meters. [C03] 8. For one chosen case of chilled water inlet temperature from Q4, determine the mass flow rate (in kg/s ) of the refrigerant of R134a and calculate the Coefficient of Performance for the chiller system. Also assume the refrigerant exits the condenser as saturated liquid. [C02] For all cases, the surrounding temperature can be assumed at 25C Report (technical writing) Your team (max 4 members) must prepare a technical written report that is presented as according to the course outcome for each part. Assignment Guidelines and Requirements QMPORTANT) - Each group MUST have MAXIMUM of three (3) persons or MINIMUM of two (2) persons. - Provide a justification/proof of works regarding all the parameters, values and design decisions that you have made. - The final design solution must be presented in a HARDCOPY technical report using the EVALUATION SHEET as a COVER PAGE and to be submitted before OR on the stated deadline. - The technical report MUST includethe following elements/evidences: - Introduction to the problem. - Methodology/Solution to the problem. - Concluston or summary that details your solution in ONE paragraph. - List of references or supporting materials. - The evidence of Student EXIT Survey for every group member REMINDER: Plagiarism is DIS-HONEST and totally UN-ACCEPTABLE. A salinity gradient solar pond (SGSP) is a simple concept of using salt water as solar collector and heat storage producing low grade temperature below 100C at the bottom layer (Poitton =1200 kg/m3) while the top layer (hog=1020kg/m3) temperature is close toambient. The middle layer acts as a transparent insulator, that has density and temperature gradient increasing with depth. Heat from SGSP can be utilised for direct heating process. Figure 1 illustrates the schematic diagram of the grain drying process using thermal heat from solar pond. The working fluids of cold low salinity brine on top layer of solar pond is pumped to extract the stored thermal heat in SGSP. The heat is channelled to dry the grain in the drying room. It involves a heating process that exposing grain to hot air with low relative humidity (RH) which will lead to evaporation of the moisture in the grain. The remaining heat is to heat up the workers pantry room that could accommodate maximum 10 persons at one time. The chiller system operates based on the vapour compression refrigeration cycle with a single stage compression. The isentropic efficiency of the compressor is assumed at 87%. The evaporator design is based on counter flow of the shell-and-tube heat exchanger. The refrigerant enters and exits through the shellat its saturation temperature, while the salinewater flows through the tube and exits the evaporator as a Chilled Water Return (CWR) tothe top layer of solar pond. For this lyeating process system: 1. Choose and justify the suitable tube specification for the 20 mmonninal diameter that to be used to transport the working fluids throughout the system. Perform a thermal resistance heat transfer analysis to determine the rate of heat extracted from solar pond in a unit length. At the same time, determine the temperature of the external sarface of the tube. [Co2] LQ= ? T0=? 2. Find the required surface area of the tube if the heat that need to be extracted is 1200 kW/m2. Then, determine the mass flow rate required in kg/s if the efficiency of the heat extraction system is 90%. [CO2] A= ? if Q=1200kdomu2Q=h.AC 3. In the dryer, the desired temperature must be in the range of 3545)C with relative humidity less than 40% to achieve a quality seed grain. If the heat adted by the heating coil is 600kW, determine the temperature of working fluids leaving the dryer and the final desired dryer temperature and Relatiye Humidity (RH). [CO2] 4. Assume that 20kW from remaining supplied thermal heat is lost prior to space heating process. Hence, determine the temperature of working fluids leaving the room as a saturated liquid and evaluate the minimum volume flow rate in m3/min to achieve the room's thermal comfort. [CO3] 5. Identify a specific multipass heat exchanger for the system. For one chosen case of chilled water inlet temperature from Q4, as well as using the LMTD method, discuss the overall heat transfer coefficient, U, profile of the evaporator if the effective surface area changes from 2m2 to 20m2, Choose the plot intervals accordingly. [CO3] 6. Based on Q5, determine the outlet temperature from the evaporator and plot the graph outlet temperature against the surface area. Justify the suitable outlet temperature as a CWR of the system. [CO2]

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts