Question: Need help question (2-a. to 2-d). Thank you Question 2. Using the following information: DEMAND AND WORKING DAYS JANUARY FEBRUARY MARCH API. MAY JUNE TOTALS

Need help question (2-a. to 2-d). Thank you

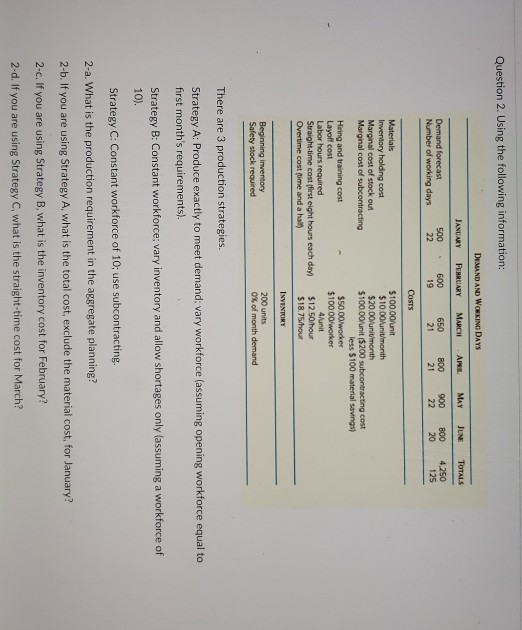

Question 2. Using the following information: DEMAND AND WORKING DAYS JANUARY FEBRUARY MARCH API. MAY JUNE TOTALS Demand forecast Number of working days 500 22 600 19 650 21 800 21 900 22 800 20 4.250 125 COSTS Materials Inventory holding cost Marginal cost of stock out Marginal cost of subcontracting $100,00/unit $10.00/unit/month $20.00/unit/month $100.00/unit ($200 subcontracting cost less $ 100 material savings) $50.00/worker $100,00/worker 4/unit $1250/hour $18.75/hour Hiring and training cost Layoff cost Labor hours required Straight-time cost first eight hours each day Overtime cost (time and a hal INVENTORY Beginning inventory Safety stock required 200 units 0% of month demand There are 3 production strategies. Strategy A: Produce exactly to meet demand; vary workforce (assuming opening workforce equal to first month's requirements). Strategy B: Constant workforce; vary inventory and allow shortages only (assuming a workforce of 10). Strategy C: Constant workforce of 10; use subcontracting. 2-a. What is the production requirement in the aggregate planning? 2-b. If you are using Strategy A, what is the total cost, exclude the material cost, for January? 2-c. If you are using Strategy B. what is the inventory cost for February? 2-d. If you are using Strategy C, what is the straight-time cost for MarchStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock