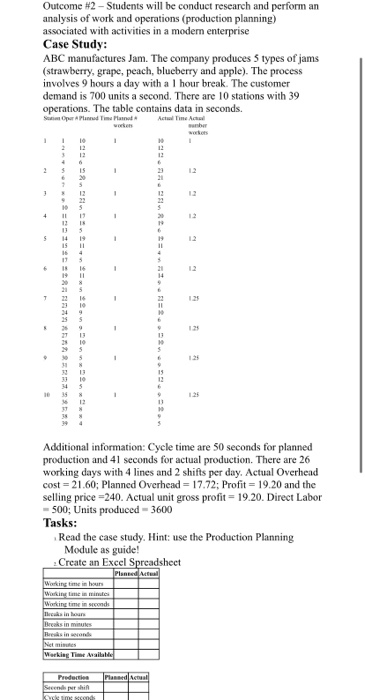

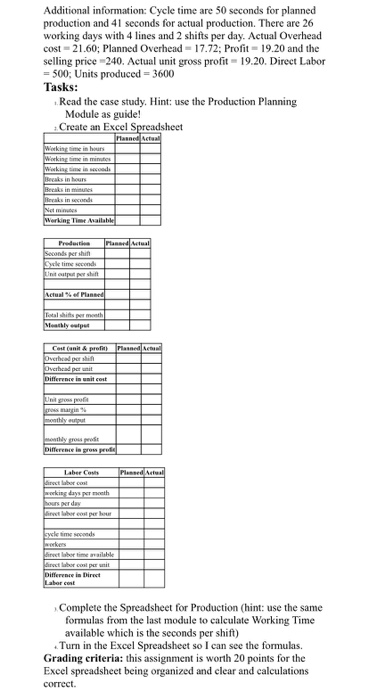

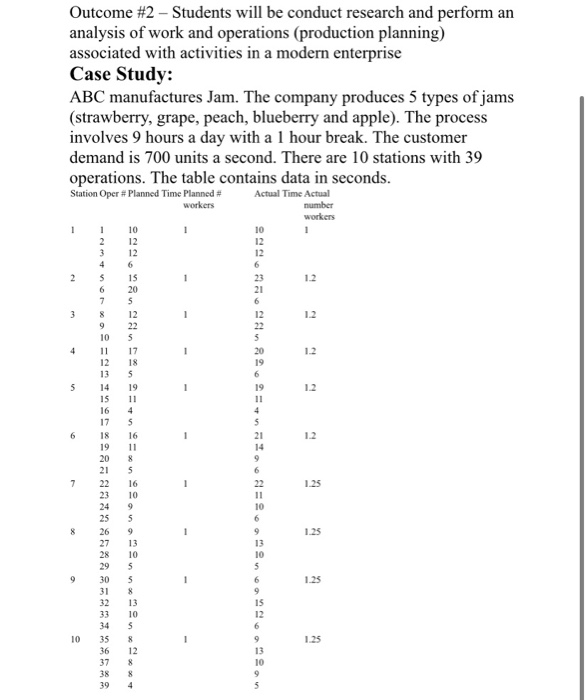

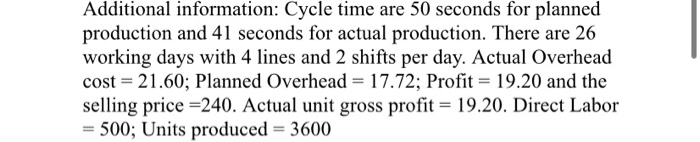

Question: Outcome #2 - Students will be conduct research and perform an analysis of work and operations (production planning) associated with activities in a modern enterprise

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock