Question: (strawberry, grape, peach, blueberry and apple). The process involves 8 hours a day with a 30 minute break. The customer demand is 500 units a

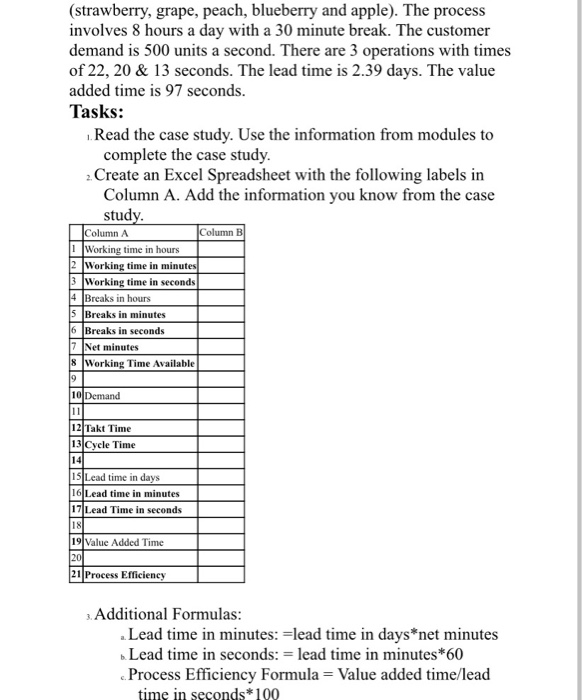

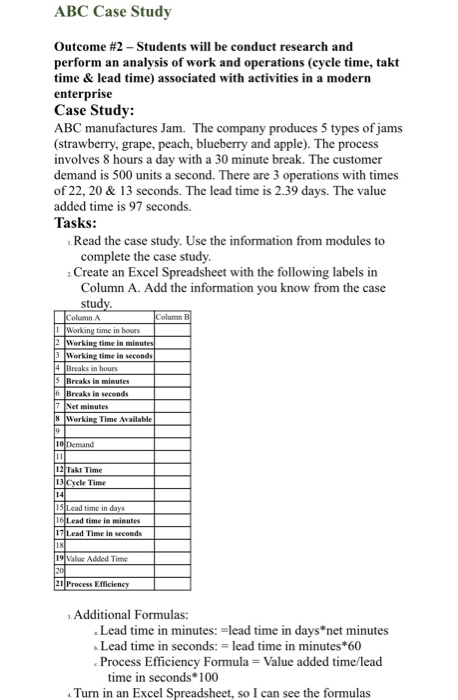

(strawberry, grape, peach, blueberry and apple). The process involves 8 hours a day with a 30 minute break. The customer demand is 500 units a second. There are 3 operations with times of 22, 20 & 13 seconds. The lead time is 2.39 days. The value added time is 97 seconds. Tasks: Read the case study. Use the information from modules to complete the case study. 2. Create an Excel Spreadsheet with the following labels in Column A. Add the information you know from the case study. Column A Column B 1 Working time in hours 2 Working time in minutes 3 Working time in seconds 14 Breaks in hours 5 Breaks in minutes 16 Breaks in seconds 17 Net minutes 8 Working Time Available 10 Demand 12 Takt Time 13|Cycle Time ISLead time in days 16 Lead time in minutes 17 Lead Time in seconds 19 Value Added Time 21 Process Efficiency Additional Formulas: .Lead time in minutes: lead time in days*net minutes Lead time in seconds: = lead time in minutes*60 Process Efficiency Formula = Value added time/lead time in seconds 100 ABC Case Study Outcome #2 - Students will be conduct research and perform an analysis of work and operations (cycle time, takt time & lead time) associated with activities in a modern enterprise Case Study: ABC manufactures Jam. The company produces 5 types of jams (strawberry, grape, peach, blueberry and apple). The process involves 8 hours a day with a 30 minute break. The customer demand is 500 units a second. There are 3 operations with times of 22, 20 & 13 seconds. The lead time is 2.39 days. The value added time is 97 seconds. Tasks: Read the case study. Use the information from modules to complete the case study. Create an Excel Spreadsheet with the following labels in Column A. Add the information you know from the case study. Column Column B 1 Working time in hours 2 Working time in minutes 3 Working time in seconds 4 Breaks in hours s Breaks in minutes 16 Breaks in seconds 7 Net minutes 8 Working Time Available 10 Demand 110 12 Takt Time 13 Cycle Time 15 Lead time in days 16 Lead time in minutes 17 Lead Time in seconds 18 19 Value Added Time 21 Process Efficiency Additional Formulas: Lead time in minutes: lead time in days net minutes Lead time in seconds: = lead time in minutes*60 Process Efficiency Formula = Value added time/lead time in seconds 100 Turn in an Excel Spreadsheet, so I can see the formulas (strawberry, grape, peach, blueberry and apple). The process involves 8 hours a day with a 30 minute break. The customer demand is 500 units a second. There are 3 operations with times of 22, 20 & 13 seconds. The lead time is 2.39 days. The value added time is 97 seconds. Tasks: Read the case study. Use the information from modules to complete the case study. 2. Create an Excel Spreadsheet with the following labels in Column A. Add the information you know from the case study. Column A Column B 1 Working time in hours 2 Working time in minutes 3 Working time in seconds 14 Breaks in hours 5 Breaks in minutes 16 Breaks in seconds 17 Net minutes 8 Working Time Available 10 Demand 12 Takt Time 13|Cycle Time ISLead time in days 16 Lead time in minutes 17 Lead Time in seconds 19 Value Added Time 21 Process Efficiency Additional Formulas: .Lead time in minutes: lead time in days*net minutes Lead time in seconds: = lead time in minutes*60 Process Efficiency Formula = Value added time/lead time in seconds 100 ABC Case Study Outcome #2 - Students will be conduct research and perform an analysis of work and operations (cycle time, takt time & lead time) associated with activities in a modern enterprise Case Study: ABC manufactures Jam. The company produces 5 types of jams (strawberry, grape, peach, blueberry and apple). The process involves 8 hours a day with a 30 minute break. The customer demand is 500 units a second. There are 3 operations with times of 22, 20 & 13 seconds. The lead time is 2.39 days. The value added time is 97 seconds. Tasks: Read the case study. Use the information from modules to complete the case study. Create an Excel Spreadsheet with the following labels in Column A. Add the information you know from the case study. Column Column B 1 Working time in hours 2 Working time in minutes 3 Working time in seconds 4 Breaks in hours s Breaks in minutes 16 Breaks in seconds 7 Net minutes 8 Working Time Available 10 Demand 110 12 Takt Time 13 Cycle Time 15 Lead time in days 16 Lead time in minutes 17 Lead Time in seconds 18 19 Value Added Time 21 Process Efficiency Additional Formulas: Lead time in minutes: lead time in days net minutes Lead time in seconds: = lead time in minutes*60 Process Efficiency Formula = Value added time/lead time in seconds 100 Turn in an Excel Spreadsheet, so I can see the formulas