Question: PART E AND F PLEASE P4-5: The liquid-phase reaction A+B-C follows an elementary rate law and is carried out isothermally in a flow sys- tem.

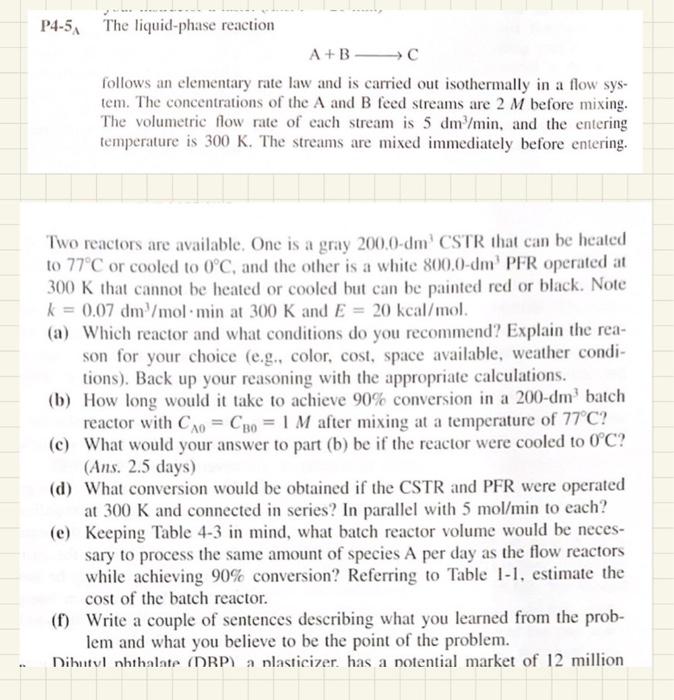

P4-5: The liquid-phase reaction A+B-C follows an elementary rate law and is carried out isothermally in a flow sys- tem. The concentrations of the A and B feed streams are 2 M before mixing. The volumetric flow rate of each stream is 5 dm /min, and the entering temperature is 300 K. The streams are mixed immediately before entering. Two reactors are available. One is a gray 200.0-dm CSTR that can be heated to 77C or cooled to 0C, and the other is a white 800.0-um PFR operated at 300 K that cannot be heated or cooled but can be painted red or black. Note K = 0.07 dm /mol min at 300 K and E = 20 kcal/mol. (a) Which reactor and what conditions do you recommend? Explain the rea- son for your choice (e.g., color, cost, space available, weather condi- Lions). Back up your reasoning with the appropriate calculations. (b) How long would it take to achieve 90% conversion in a 200-dm batch reactor with CA = CBo = 1 M after mixing at a temperature of 77C? (c) What would your answer to part (b) be if the reactor were cooled to 0C? (Ans. 2.5 days) (d) What conversion would be obtained if the CSTR and PFR were operated at 300 K and connected in series? In parallel with 5 mol/min to each? (e) Keeping Table 4-3 in mind, what batch reactor volume would be neces- sary to process the same amount of species A per day as the flow reactors while achieving 90% conversion? Referring to Table 1-1, estimate the cost of the batch reactor. (1) Write a couple of sentences describing what you learned from the prob- lem and what you believe to be the point of the problem. Dibutul nhthalate (DBP) a plasticizer. has a potential market of 12 million

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts