Question: Please answer a-d. Consider a small production system for manufacturing two products, X and Y as shown below. Manufacturing X requires two raw materials (RM

Please answer a-d.

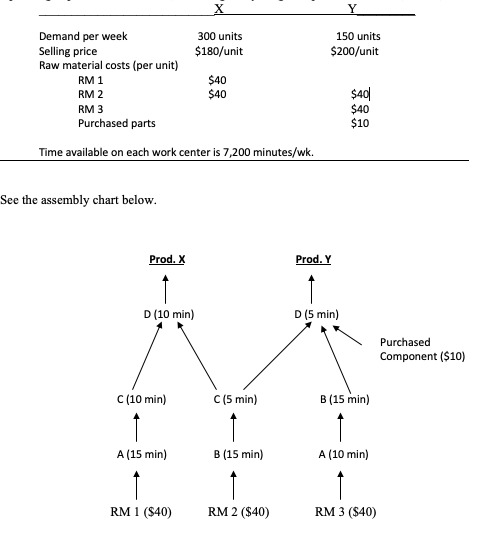

Consider a small production system for manufacturing two products, X and Y as shown below. Manufacturing X requires two raw materials (RM 1 and 2). Manufacturing Y also requires two raw materials (RM 2 and 3). In addition, Y uses a purchased component that costs $10 per unit. Four work centers (A, B, C, and D) are used to manufacture the products. Each has 7,200 minutes (120 hours; 3 eight-hour shifts) available each week. Operating expenses for the week, including everything except materials costs, is $12,000.

a. What is the maximum potential profit of the production system?

- Find the bottleneck work center. Show why it is a constraint.

- What is the maximum feasible amount of profit subject to the constraint?

- The manager plans to purchase a new technology at $750,000 to reduce the processing time on both RM 2 and RM 3 at the bottleneck workstation by half. What would you say about his plan? Discuss.

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts