Question: Please answer both A and B... 4.11 Dimethyl malonate is produced by the following chemistry: ClmonochloracticacidCH2COOH+sodiummonochlorascetaleNaOHClCCH2COONa+H2O sodiummonochloroacceateClCH2COONa+sodiumcyanoacetaleNaCNNCCH Monochloroacetic acid in water is mixed with cracked

Please answer both A and B...

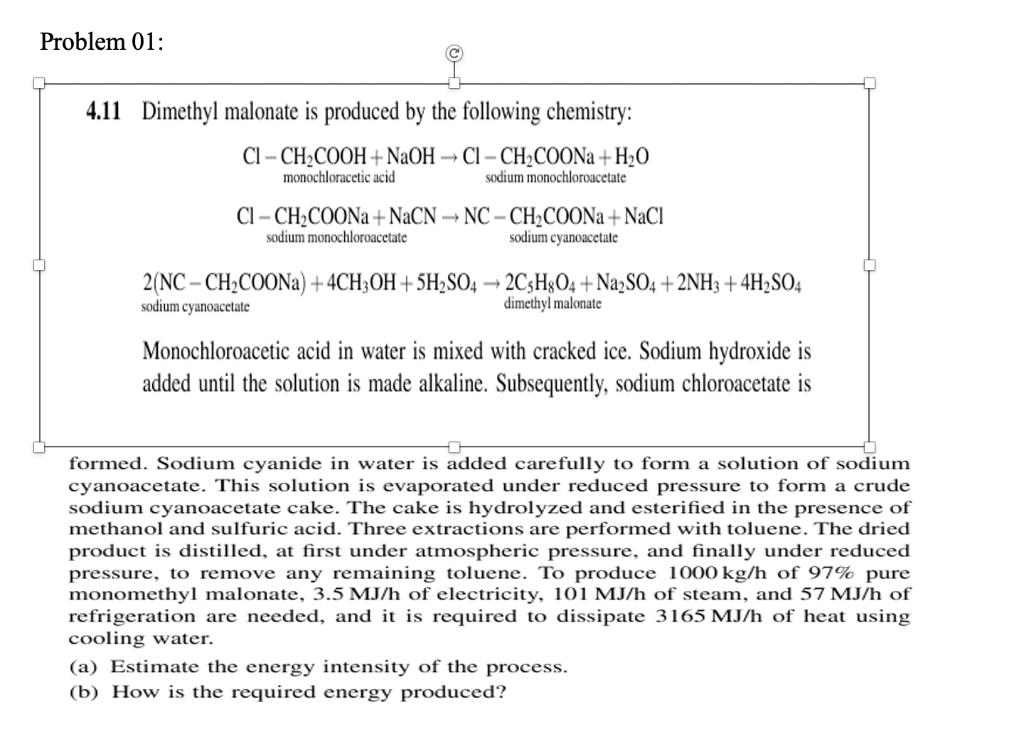

4.11 Dimethyl malonate is produced by the following chemistry: ClmonochloracticacidCH2COOH+sodiummonochlorascetaleNaOHClCCH2COONa+H2O sodiummonochloroacceateClCH2COONa+sodiumcyanoacetaleNaCNNCCH Monochloroacetic acid in water is mixed with cracked ice. Sodium hydroxide is added until the solution is made alkaline. Subsequently, sodium chloroacetate is formed. Sodium cyanide in water is added carefully to form a solution of sodium cyanoacetate. This solution is evaporated under reduced pressure to form a crude sodium cyanoacetate cake. The cake is hydrolyzed and esterified in the presence of methanol and sulfuric acid. Three extractions are performed with toluene. The dried product is distilled, at first under atmospheric pressure, and finally under reduced pressure, to remove any remaining toluene. To produce 1000kg/h of 97% pure monomethyl malonate, 3.5MJ/h of electricity, 101MJ/h of steam, and 57MJ/h of refrigeration are needed, and it is required to dissipate 3165MJ/h of heat using cooling water. (a) Estimate the energy intensity of the process. (b) How is the required energy produced

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts